Walther Valve Controller WVC

The Walther Valve Controller (WVC) is a compact and versatile control unit for spray, pulse, and dosing valves. It combines comprehensive control functions with sophisticated process monitoring, making the controller ideally suited to the requirements of Industry 4.0.

Customised control options for stable dosing processes: The WVC Valve Controller individually controls the parameters relevant to the process. Preconfigured process settings are available for each dosing type – pulsing, spraying, dosing. The respective parameters, such as valve opening and closing times, can be optimally adjusted and precisely repeated to match the required process. A wide range of freely configurable connections within the device allows additional components and functions to be integrated at any time. Versatile connectivity enables integration of process sensors – such as temperature and pressure sensors, stroke monitoring, and volumetric flow meters – as well as actuators (e.g., directional control valves) within a single device, eliminating the need for additional control units.

Extended process monitoring and analysis for optimal quality: The integrated monitoring function of the WVC enables real-time documentation and analysis of the set process parameters. Alerts can be triggered based on predefined threshold values. This ensures targeted monitoring of the process, evaluation of deviations, and immediate transmission of notifications. This results in a wide range of opportunities to improve product quality, process capability, and overall equipment effectiveness (OEE).

User-friendly interface for efficient parameterisation and remote diagnostics: The central tool for configuring and adjusting the WVC is the password-protected web dashboard, which enables direct access via PC, tablet, or smartphone for control and process monitoring. Thanks to its intuitive graphical interface, the dashboard offers a highly intuitive process visualisation. Additionally, the most important process parameters can be accessed and adjusted directly via the HMI on the device. No expert knowledge or programming experience is required for parameterisation!

Centralised control and seamless integration: With its available interfaces, the WVC offers various integration options into higher-level control systems. For example, it can be easily integrated into existing automation systems via freely configurable digital I/Os or Modbus TCP.

The WVC represents a newly conceived control and process monitoring solution for application processes, helping to integrate them safely, easily, and conveniently. To meet different user requirements, the WVC is available in three expansion stages:

- BASIC: Control unit for precise timing of spray, pulse, and dosing valves, including heating control.

- ADVANCED: Increased process reliability through additional sensor and process evaluation options (e.g., pressure sensor, valve needle stroke, light barrier).

- PROFESSIONAL: Capability to implement closed-loop control with a volumetric flow sensor and additional process monitoring.

Optional software add-ons such as Modbus and Multi-Parameter Set can be activated at any time using an activation code to flexibly adapt the controller to changing requirements.

Additional information on the WVC-PROFESSIONAL can be found here >>

- compatible with most conventional valves; also outside the Walther product portfolio

- cost- and time-saving integration without additional control technology, software, or programming, allowing easy commissioning and direct control via a web interface

- reduce rejects and enhance process quality through continuous process monitoring

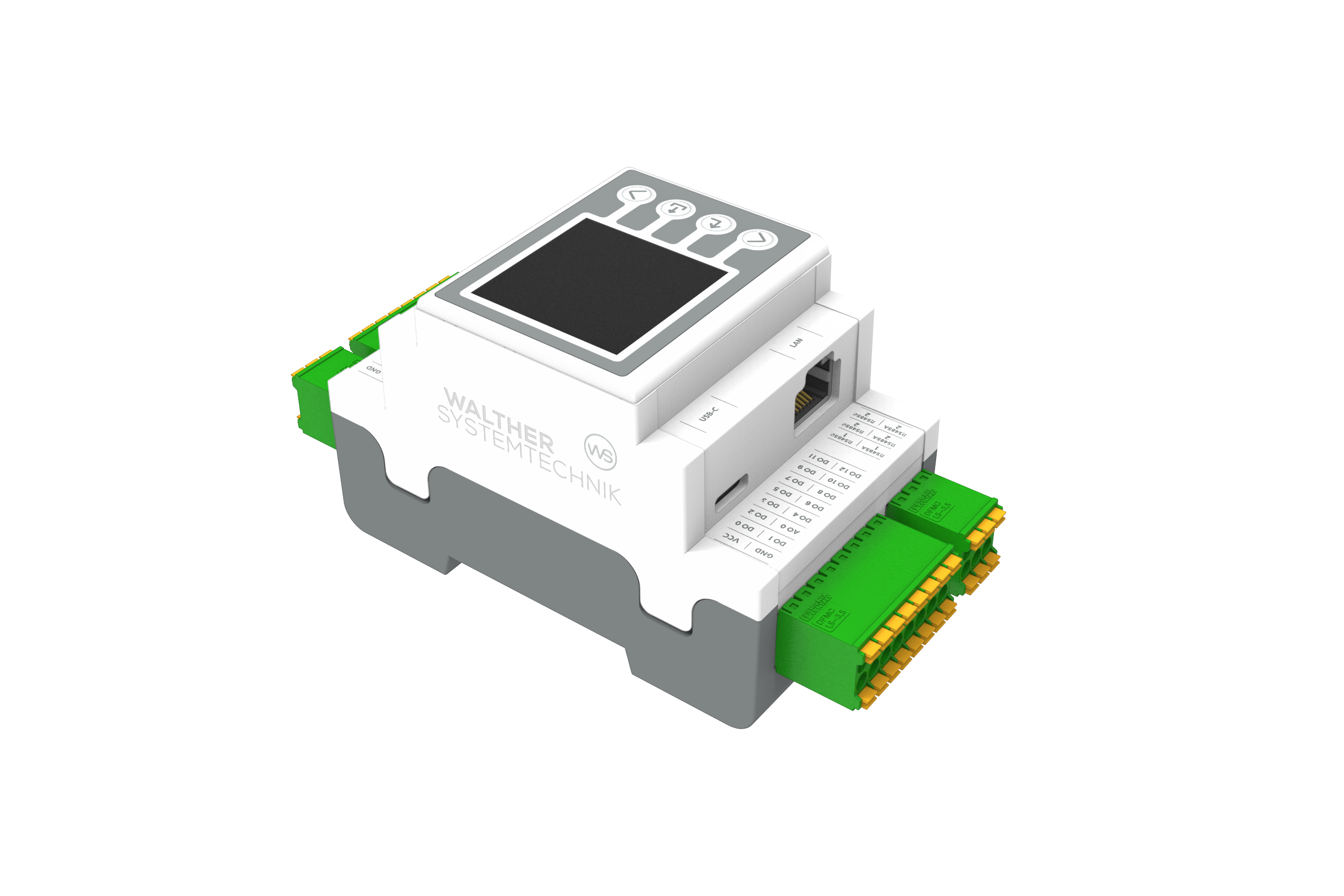

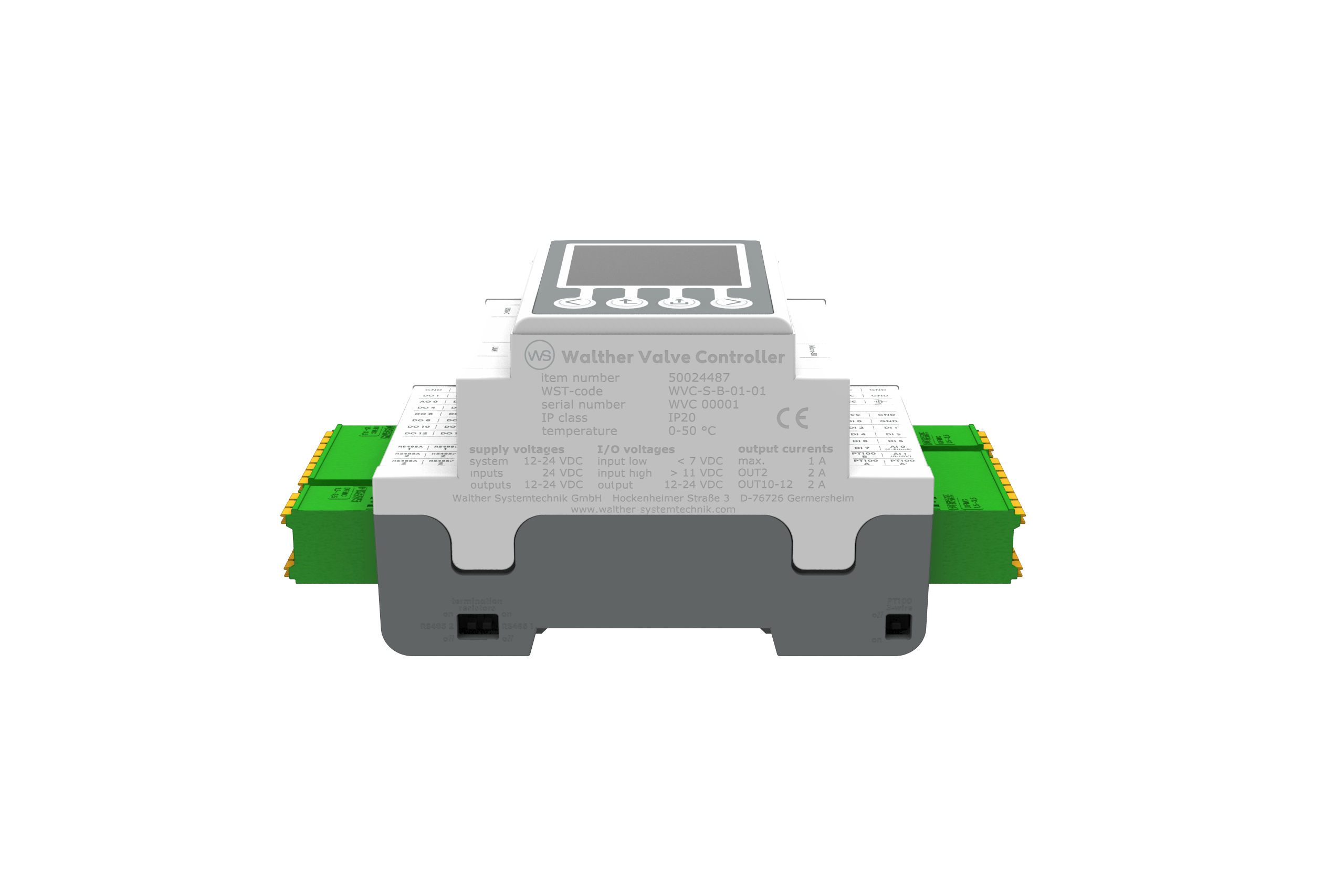

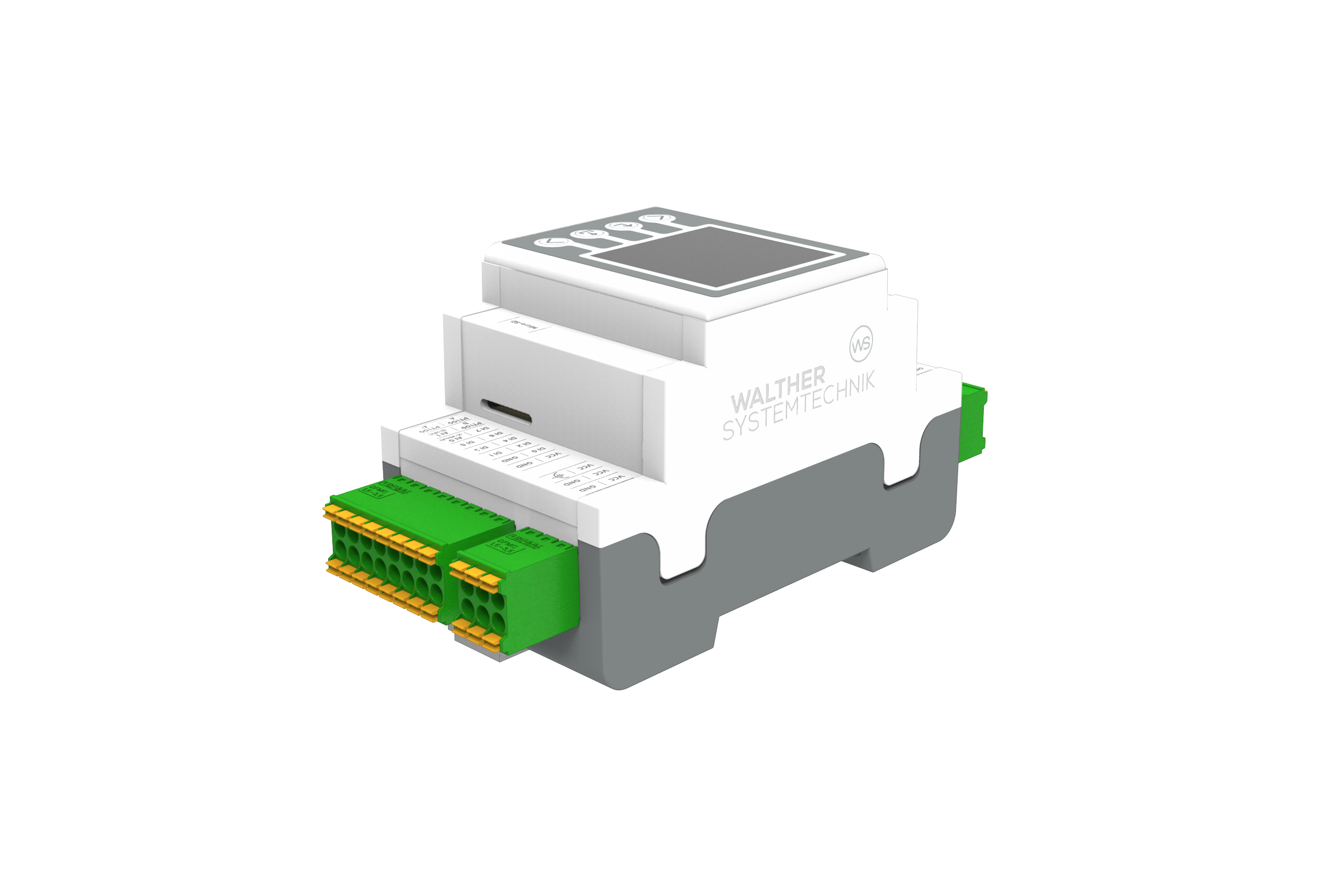

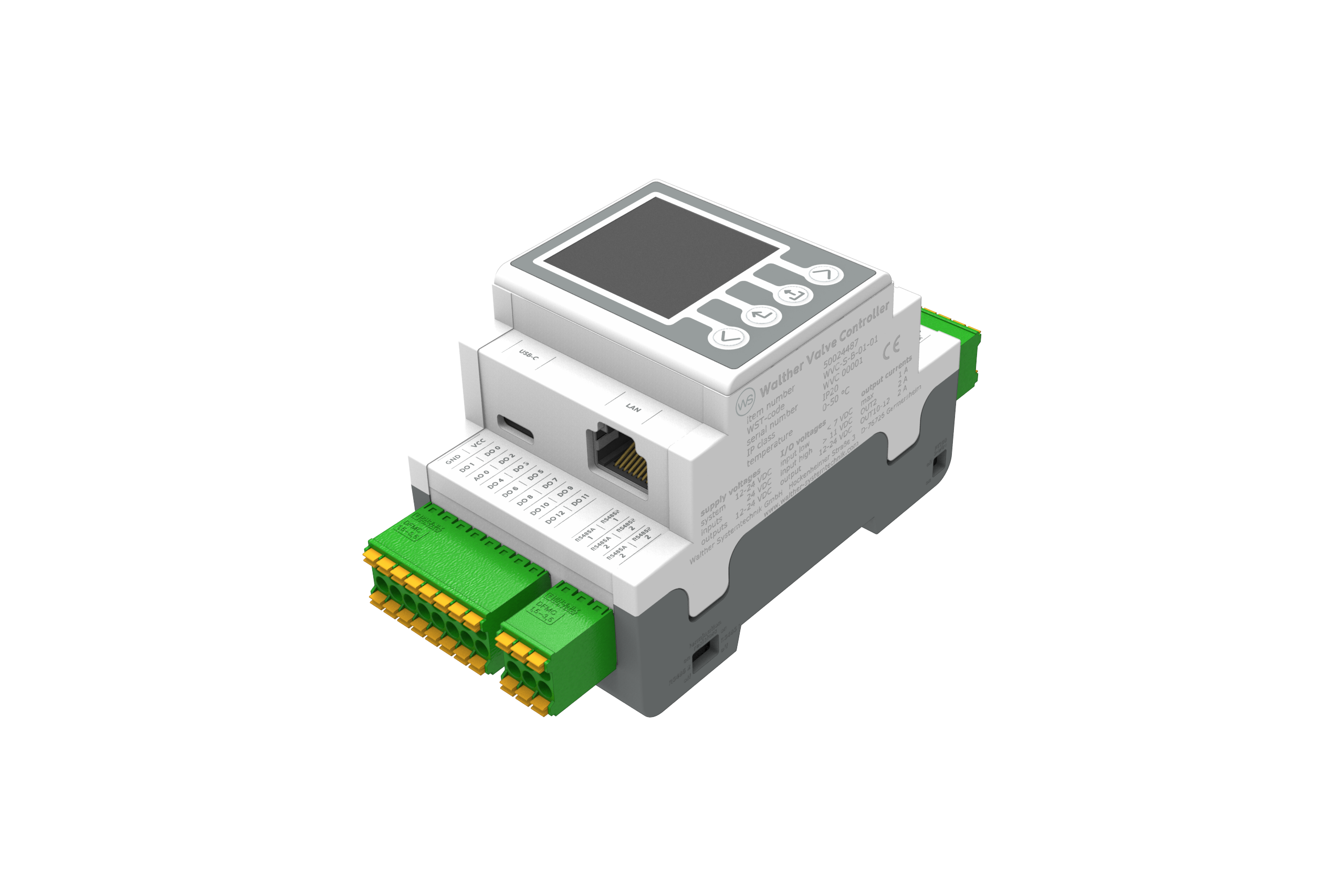

- dimensions (l x w x h): 122 x 53 x 58 [mm]

- weight: 160 [g]

- operation voltage: 24 [VDC]

- temperature range: 10 to 50 [°C]

- interfaces:

>> 8x digital input 24 [VDC]

>> 1x analog input 4...20 [mA]

>> 1x analog input 0...10 [VDC]

>> 1x PT 100 input

>> 8+3x digital output 24 [VDC]

>> 1x analog output 4...20 [mA]

>> 1x Ethernet (Modbus Tcp & TCP/IP)

- IP class: IP20