Walther Pulse Valve WPV

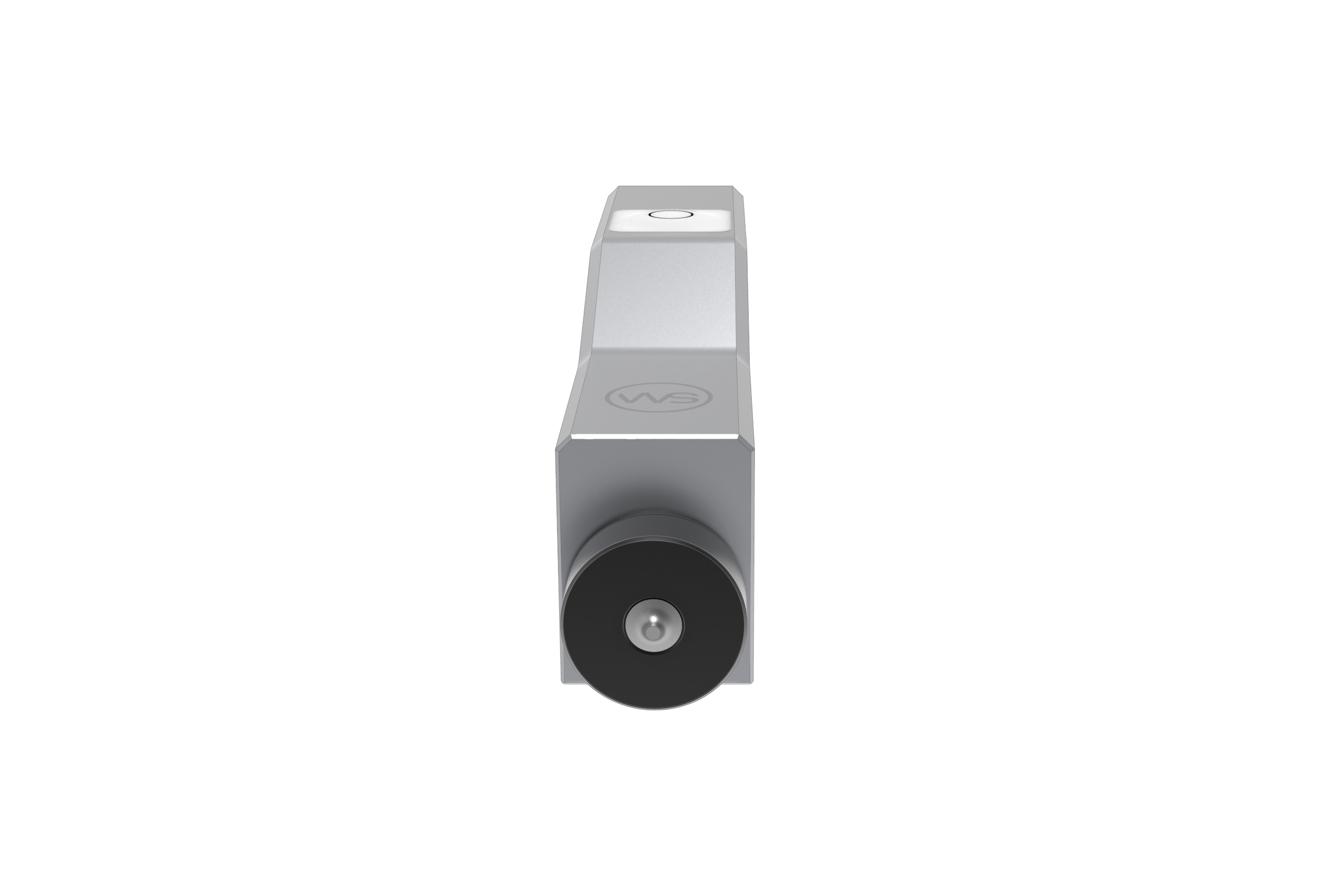

The WPV Pulse Valve is an innovative, electrically operated dispensing valve designed for the precise, contactless application of low- to medium-viscosity media. Its fully electric operation eliminates the need for compressed air lines, reducing installation requirements and simplifying integration into existing production environments. With a compact design (134.5 x 25 x 45 mm) and integrated electronics, the WPV Pulse Valve can be directly integrated into new and existing production systems without additional control technology, software, or programming. An Ethernet-based bus system enables complete parameterization and visualization of all process parameters via the web interface, allowing configuration and diagnostics to be conducted both directly and remotely.

Integrated Features for High Process Reliability and Flexibility: The WPV Pulse Valve is designed for versatile dispensing applications, featuring an integrated valve heater with temperature control for precise medium tempering and a pressure sensor for analyzing the process pressure profile. The four digital inputs/outputs (DIOs) allow direct control of peripheral devices, enhancing flexibility. An integrated push button enables manual valve actuation for immediate application and inspection, supporting quick commissioning and maintenance. An LED status indicator provides a continuous display of the operating state.

Variants: To meet diverse application requirements, the WPV Pulse Valve is available in three specific versions. The BASIC version is the standard model, with integrated control and parameterization through the web interface. The ADVANCED version includes additional temperature control for medium tempering. The PROFESSIONAL variant offers comprehensive process control, including monitoring and evaluation of the process pressure profile.

Software add-ons, such as "Ethernet Bus System," "Valve Needle Stroke Monitoring," and "Multi-Parameter Sets," are available as optional functionality extensions for all valve variants. Firmware updates, accessible online, ensure continuous optimization of valve functions.

Enhanced Process Control for Maximum Efficiency: The WPV Pulse Valve supports real-time monitoring and documentation of process parameters, enabling easy, specific adjustment and optimization to meet individual process requirements. The valve can be configured and diagnosed remotely via the web interface, while configurable alarms and notifications based on defined process parameters enable targeted process monitoring.

Compact Design and Cost Efficiency: All versions of the WPV have identical dimensions, simplifying installation and integration across various production systems. The modular design of the valve also allows for the selective replacement of individual components, minimizing maintenance costs and downtime. Compared to conventional pulse or jet valves with external pressure and temperature modules, the WPV is an economically advantageous solution that also reduces operational costs due to its electric operation.

The WPV Pulse Valve provides users with a cost-effective, compact, and flexible solution, setting new standards in the contactless application of low- to medium-viscosity media through advanced monitoring and control technology.

- fast and easy commissioning and direct control via web interface

- cost- and time-saving integration without additional control technology, software, or programming

- purely electrical operation without compressed air

- reduction of waste and improvement of process quality through continuous process monitoring

- inlet pressure (medium): max. 50 [bar]

- inlet pressure (atomizer air): max. 6 [bar]

- supply voltage: 24 [VDC]

- valve heating: 0 to 80 [°C]

- ambient temperature: -5 to +45 [°C]

- needle stroke adjustment: min. 0.01 [mm]

- analog outlet: 4 to 20 [mA]

- digital I/O: 4 each 24 [VDC]