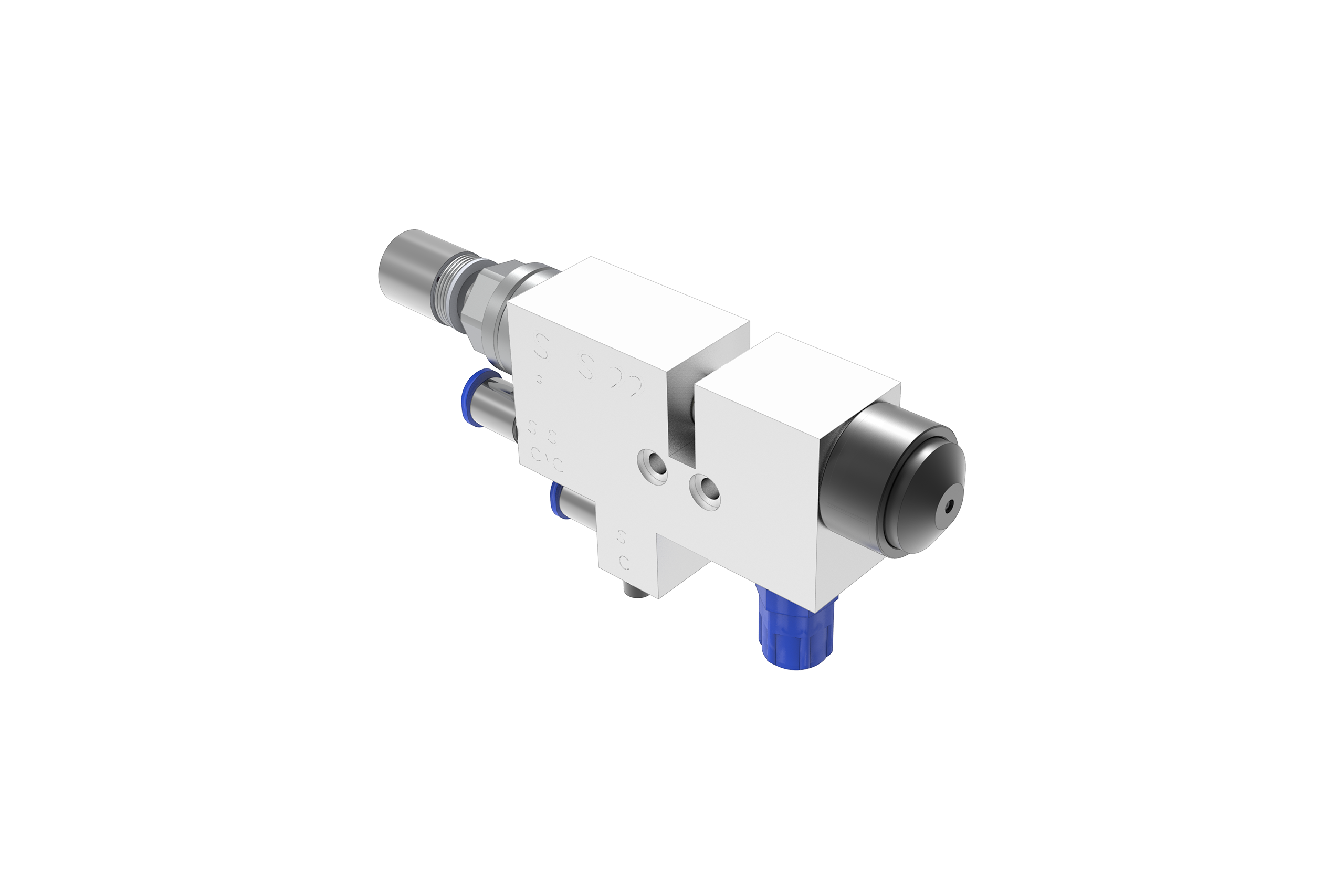

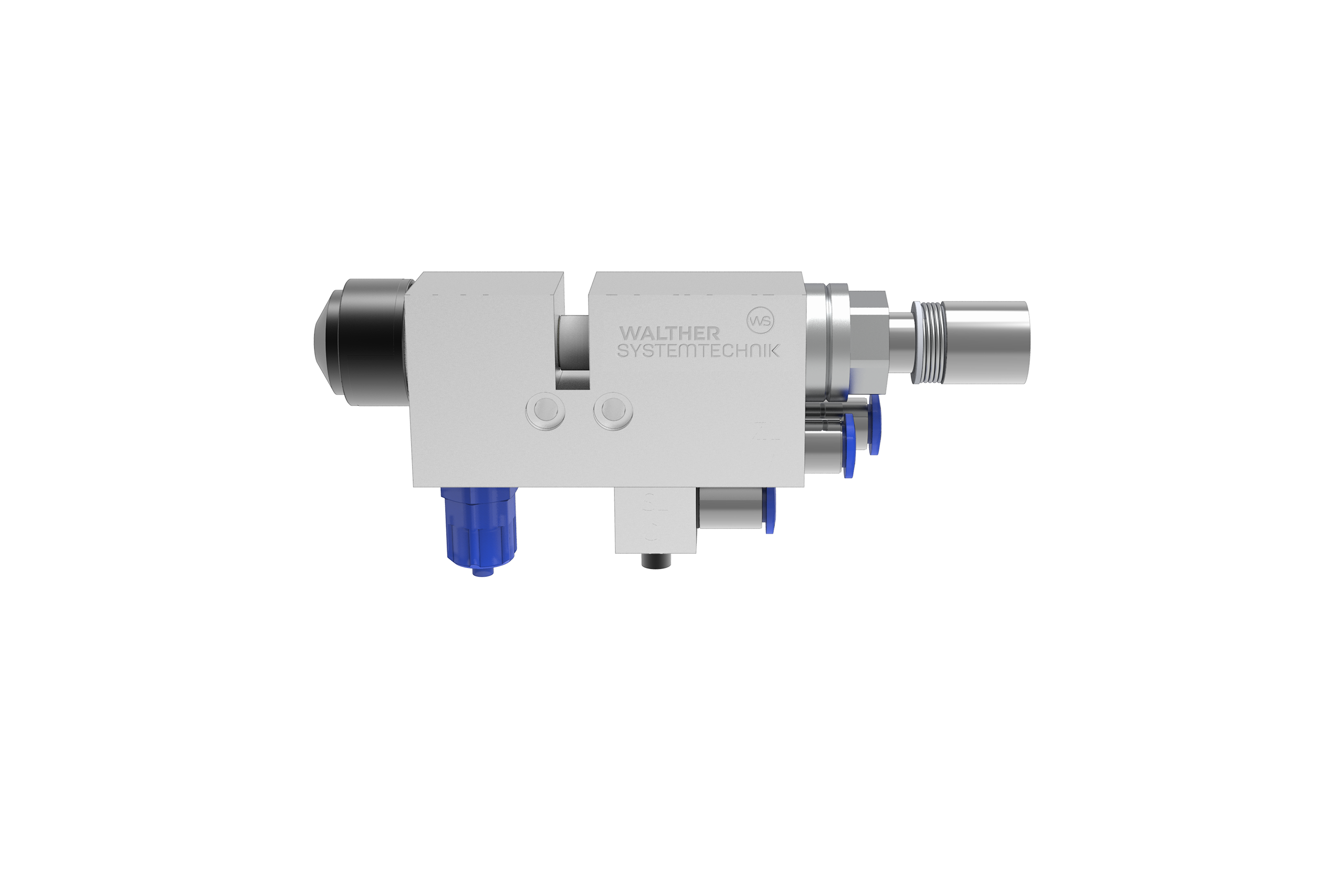

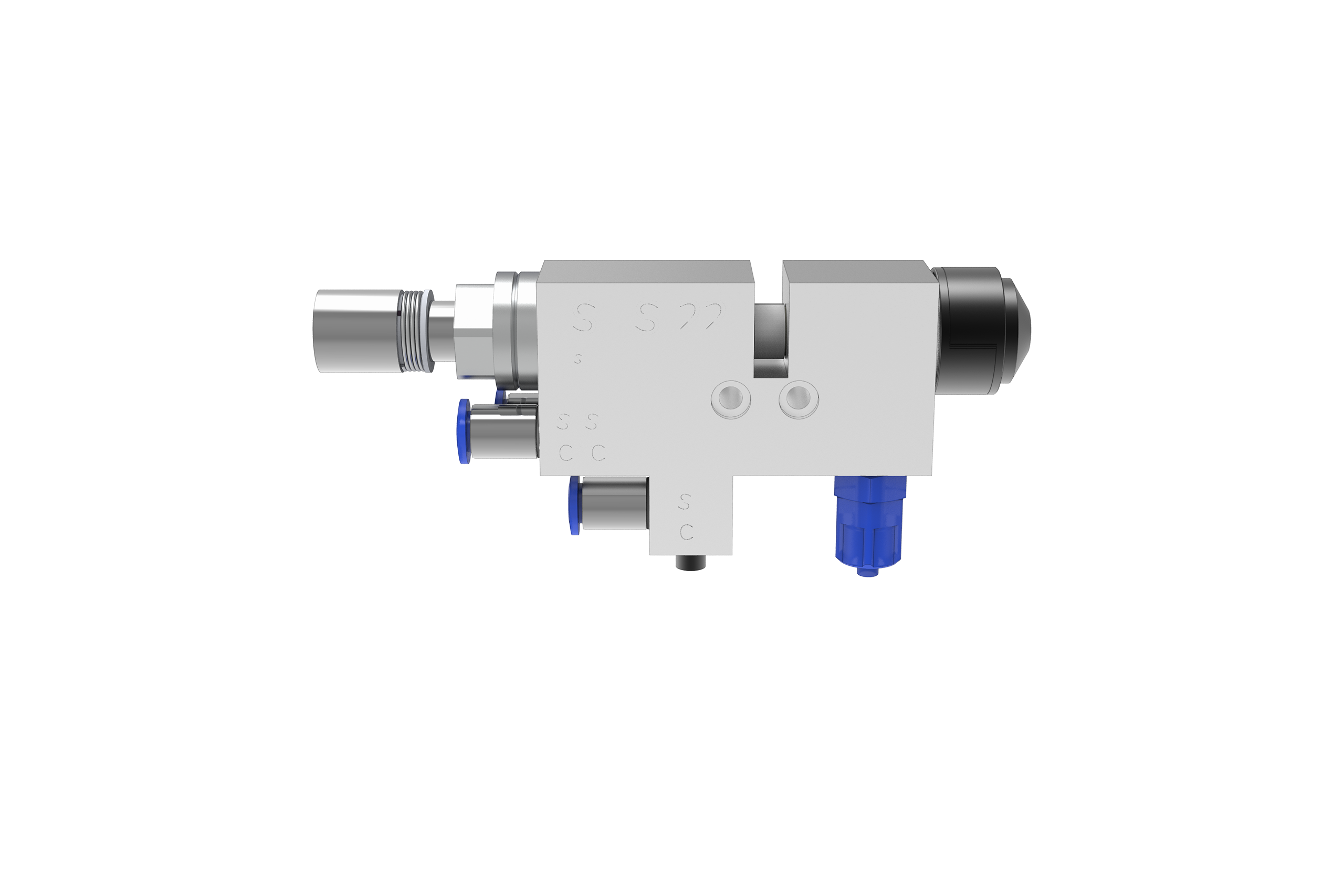

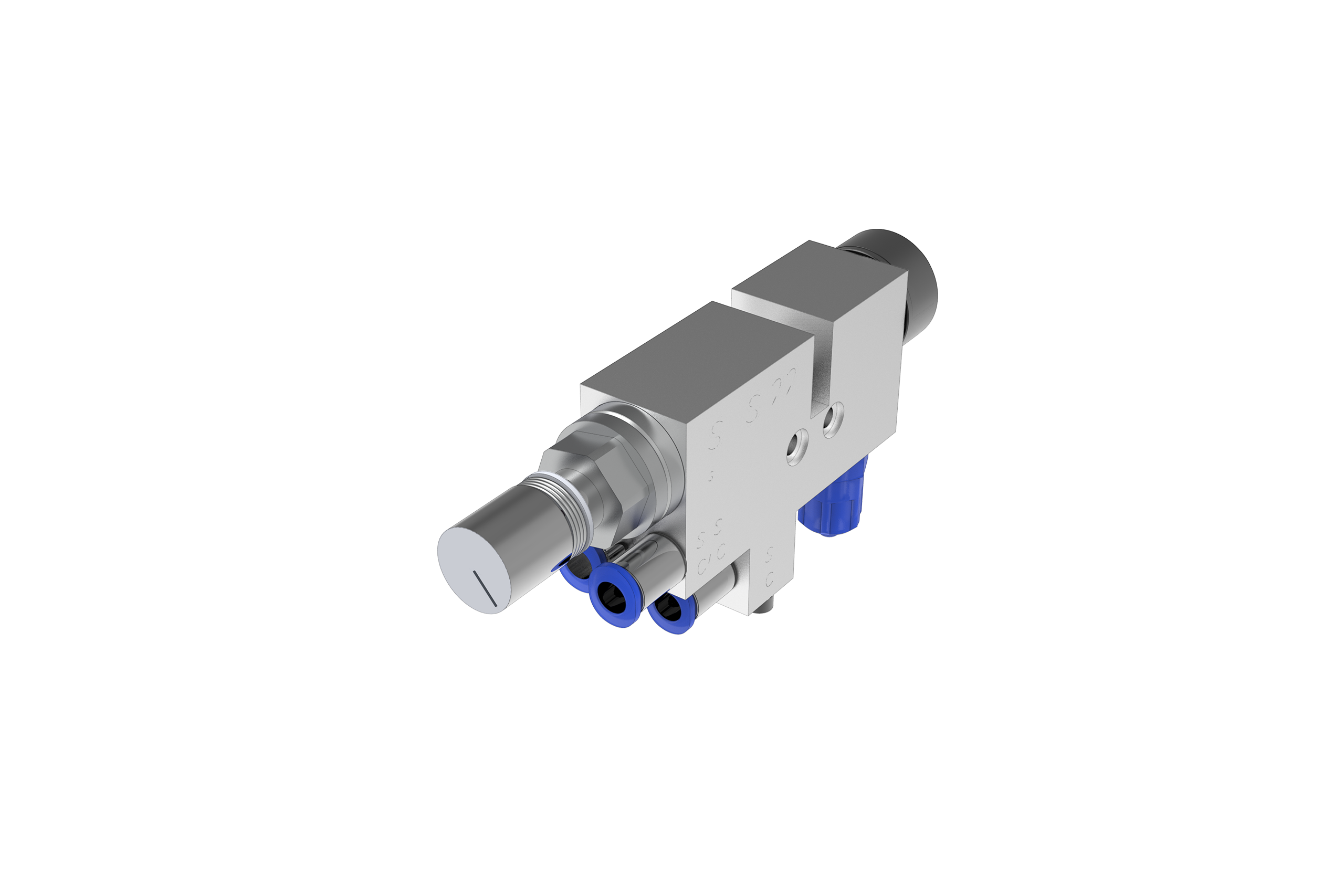

Spray Valve SMS-22

Gas inclusions in a medium can abruptly explode when leaving the dosing valves; this may not only cause a reduction in dosing quantity and an incorrect application image; in some cases, it can also damage the dosing valves and the system.

The Air Bubble Protection System protects your system. It will automatically detect gas and air inclusions in the medium and will reliably discharge these. It is a compact and very efficient system which was particularly designed for conditioning liquid and viscous media. The device allows you a continuous monitoring of the volume flow and reduces material losses to a minimum, thanks to its detection and separation precision.

When in use, the Air Bubble Protection is able to monitor different process values and will signal any exceeding or falling-below of pre-defined limit values. The system also has a display which shows the operating status or events and is used for direct configuration. A password protection will prevent unauthorized changes.

As a module of the Modular Series, the ABPS has a compact design, can be easily installed and can be integrated in any dosing and application system. Above that, flanging it to other modules of the series is fast and easy.

- pneumatically controlled, active closing of valve needle

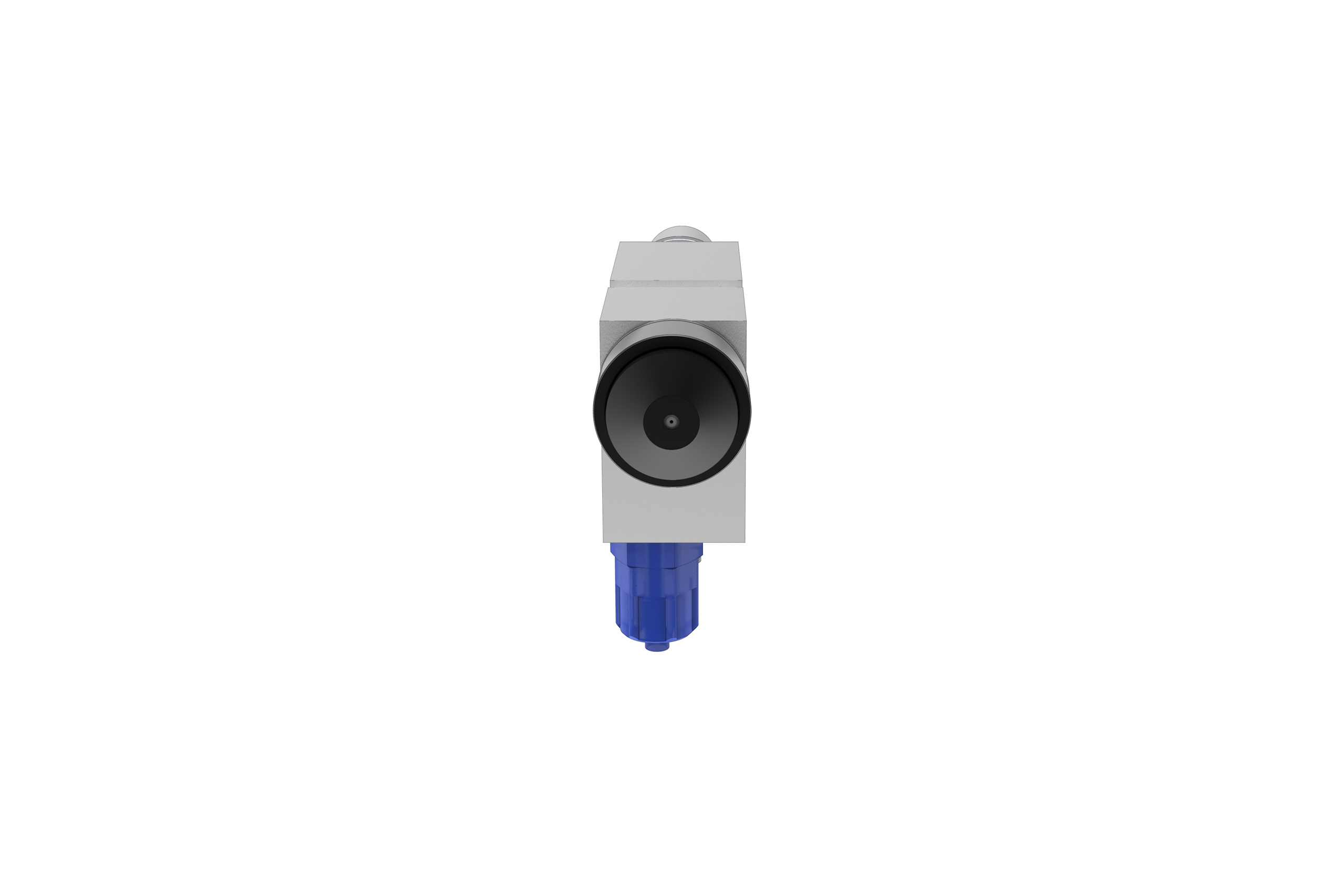

- different nozzles and air cap combinations for a perfect adaptation to the desired spraying image

- for complex spraying tasks, we offer a variety of adapted nozzle extensions optionally

- optional heating plate available for tempering the valve body

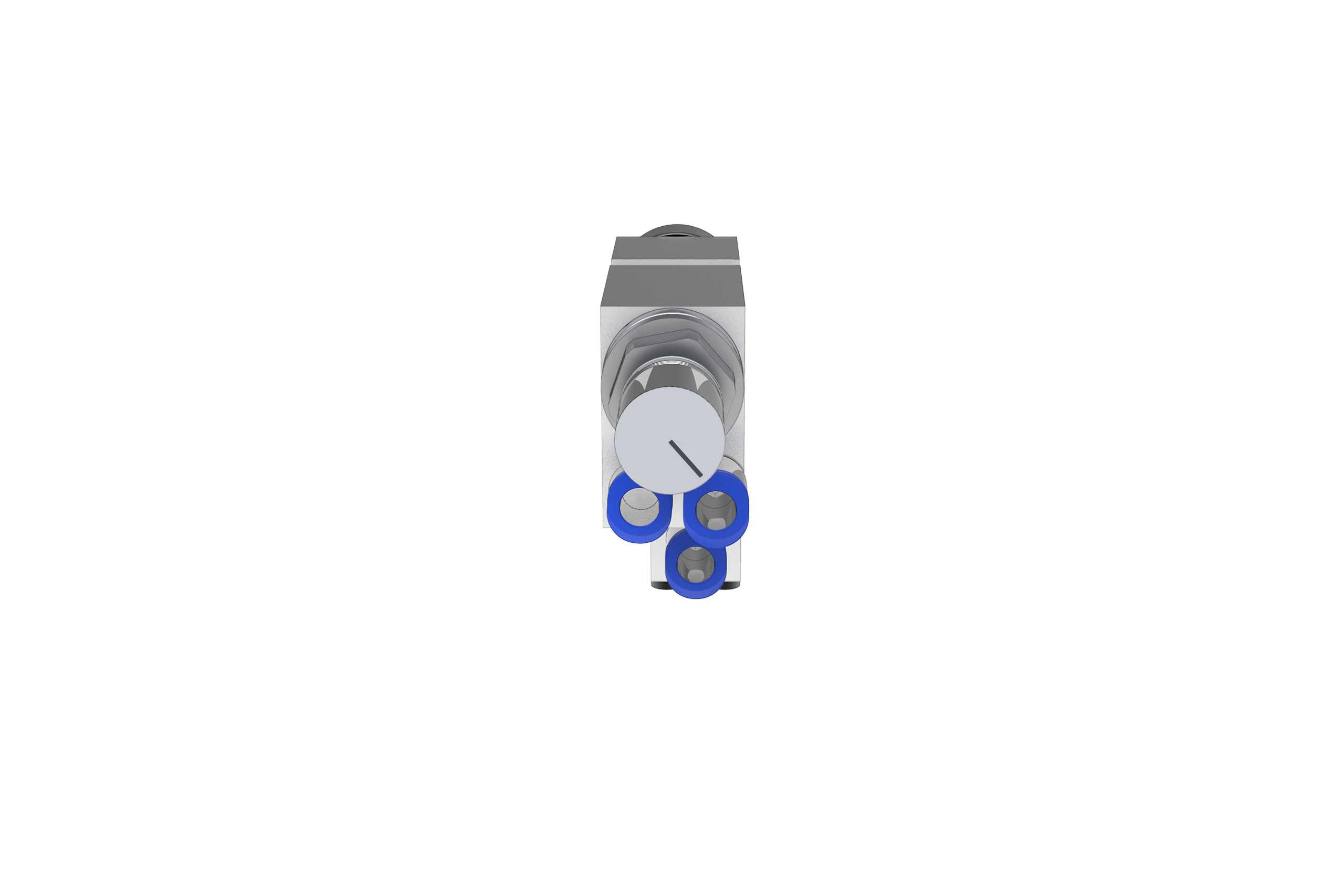

- atomizer air and control air controlled independently

- process pressure: max. 35 [bar]

- control air pressure: min. 5 to 6 [bar]

- atomizer air pressure: 0,5 to 5 [bar]

- process connection (medium): G1/4" incl. hose screw joint 6/4

- process connection (air): hose screw joint 6/4

- dimensions (l x w x h): 131 x 23,5 x 57,5 [mm]

- weight: 0,5 [kg]

- nozzle & needle: optionally hardened (kolsterised)