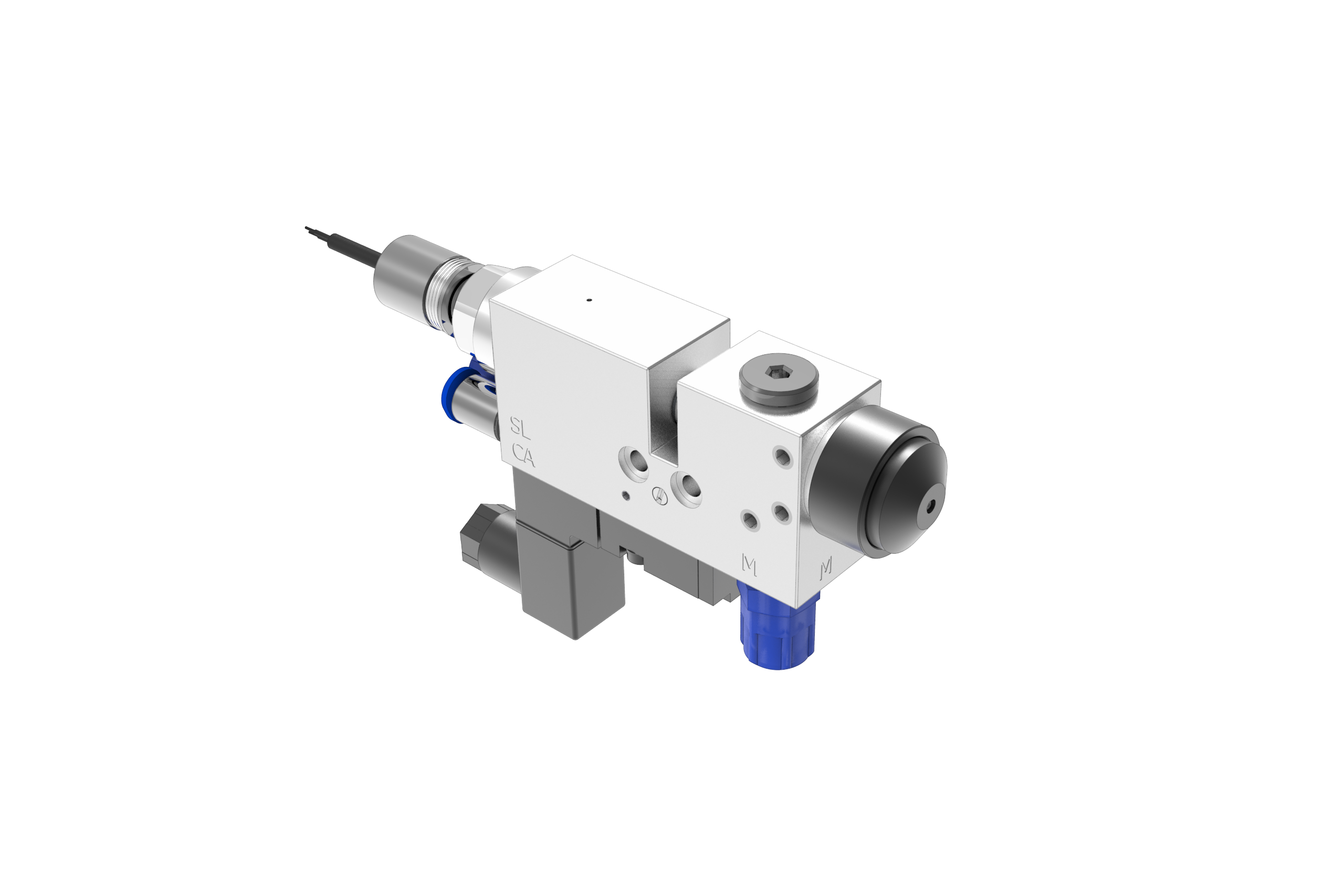

Spray Valve SMS-02

The SMS-02 spray valves are perfect for intermittent or continuous use with oils, separating agents, paint, and greases. These valves feature a precise electro-pneumatic 5/2-way valve for parallel control of the valve needle and atomizer air.

Product number:

SMS-02-E-N-N-T00-00-R15-KLS08

Order code:

SMS-02-E-N-N-T00-00-R15-KLS08

Spraying low to medium viscous media is one of the most common application types in almost any business. The correctly applied spray quantity plays an important role and so does the required spraying image which will guarantee the proper function of the applied medium.

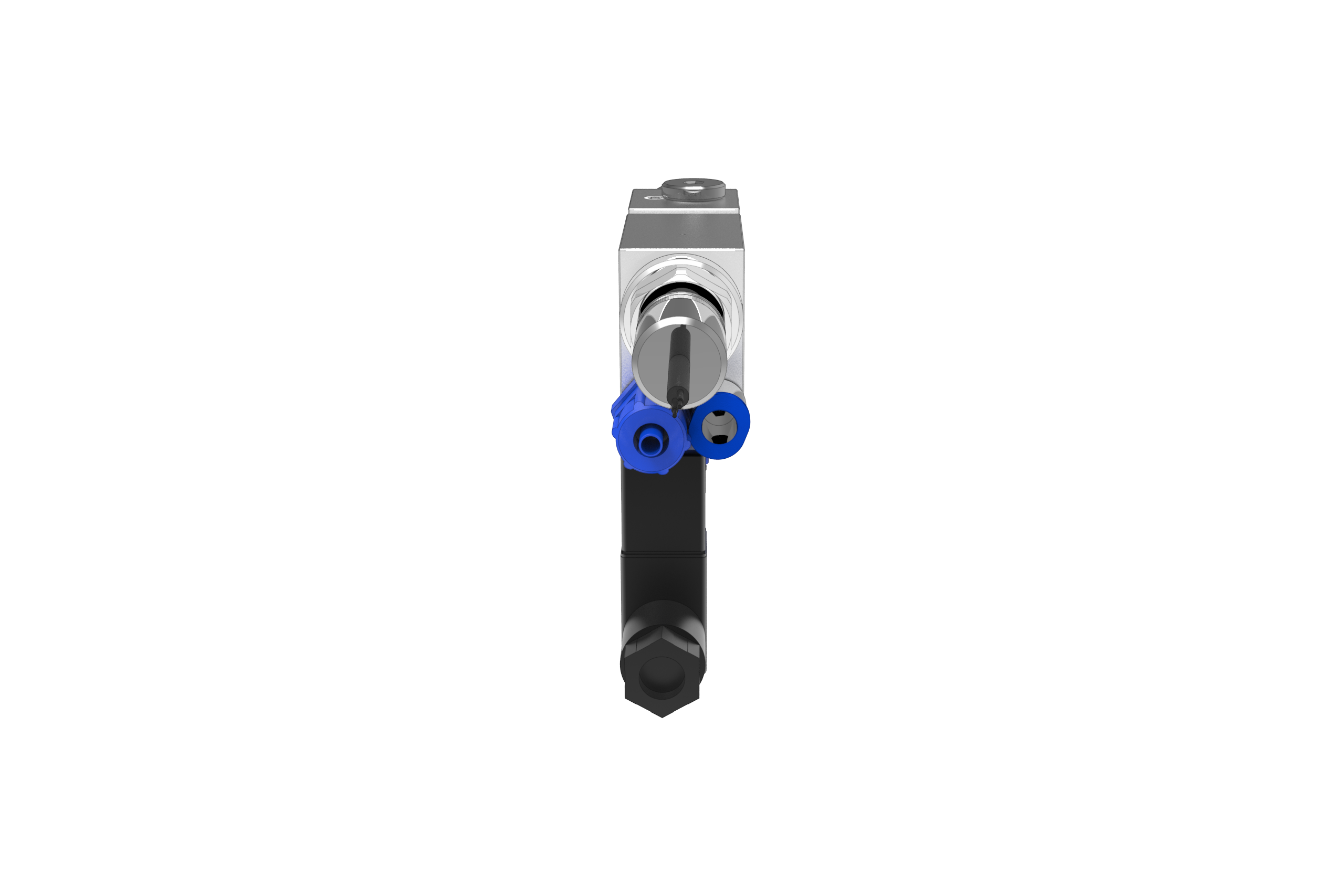

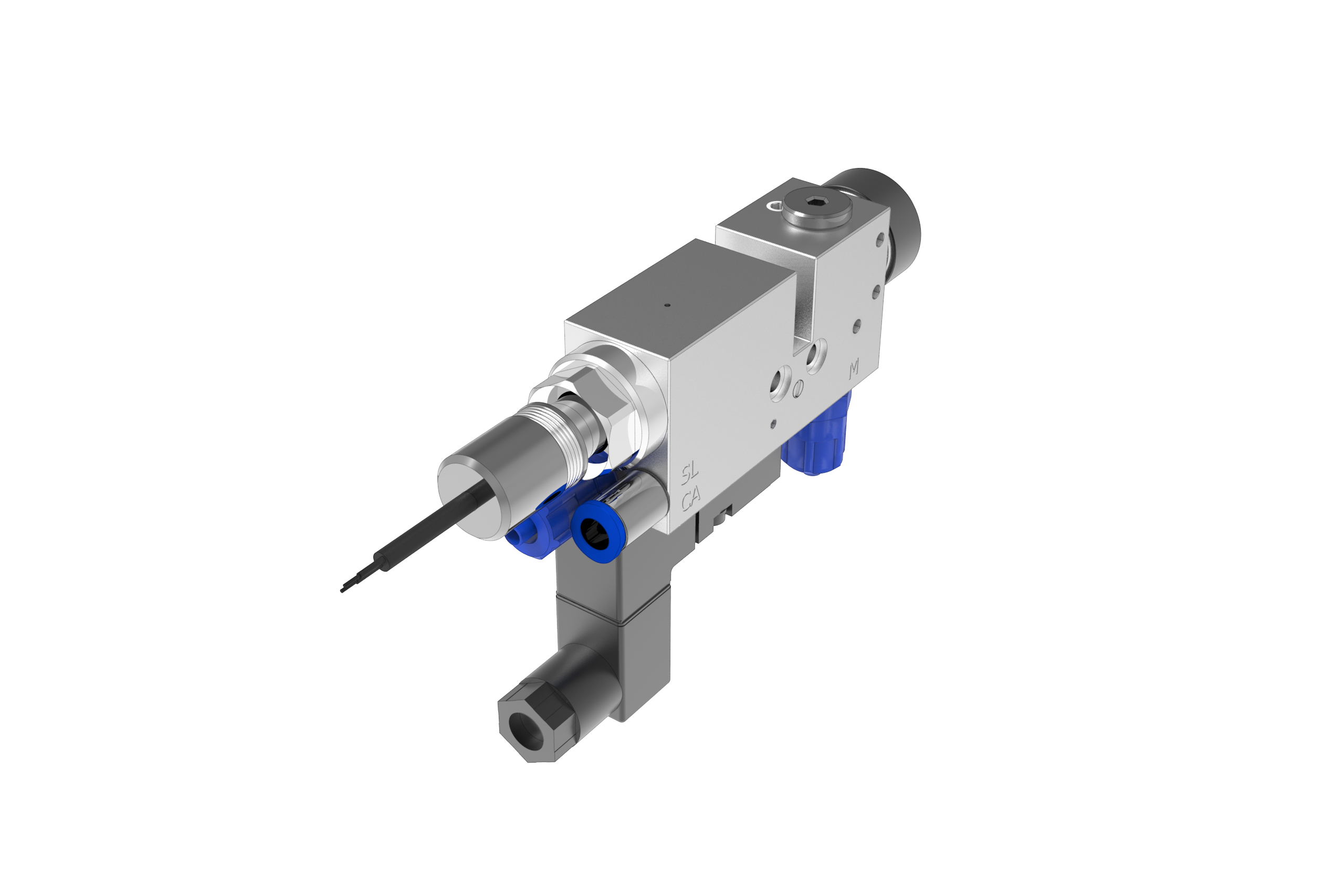

The SMS-02 Spray Valve is electro-pneumatically controlled which is the decisive factor for your optimum spraying process! Individual nozzle sizes, adjustable medium flow and atomizer air pressure, an integrated control piston for regulating the duration of the post-air, as well as extremely short control air distances for fast and very precise opening and closing movements of the needle.

All these features allow you an excellent, individual control of the spraying process without waste of material, contamination or over-spraying. Spray valves of the SMS-02 series are suitable for an intermitting or a continuous application of liquid media such as greases, oils, separating agents, paints and 1-component glue media such as polyurethane, epoxide, silicone and MS-polymers.

Depending on the air cap, you can produce a round jet or a flat jet.

- no additional pneumatic valve required for controlling the atomizer air

- different nozzles and air cap combinations for a perfect adaptation to the desired spraying image

- optional sensor available for monitoring the valve needle stroke

- for complex spraying tasks, we offer a variety of adapted nozzle extensions optionally

- optional heating plate available for tempering the valve body

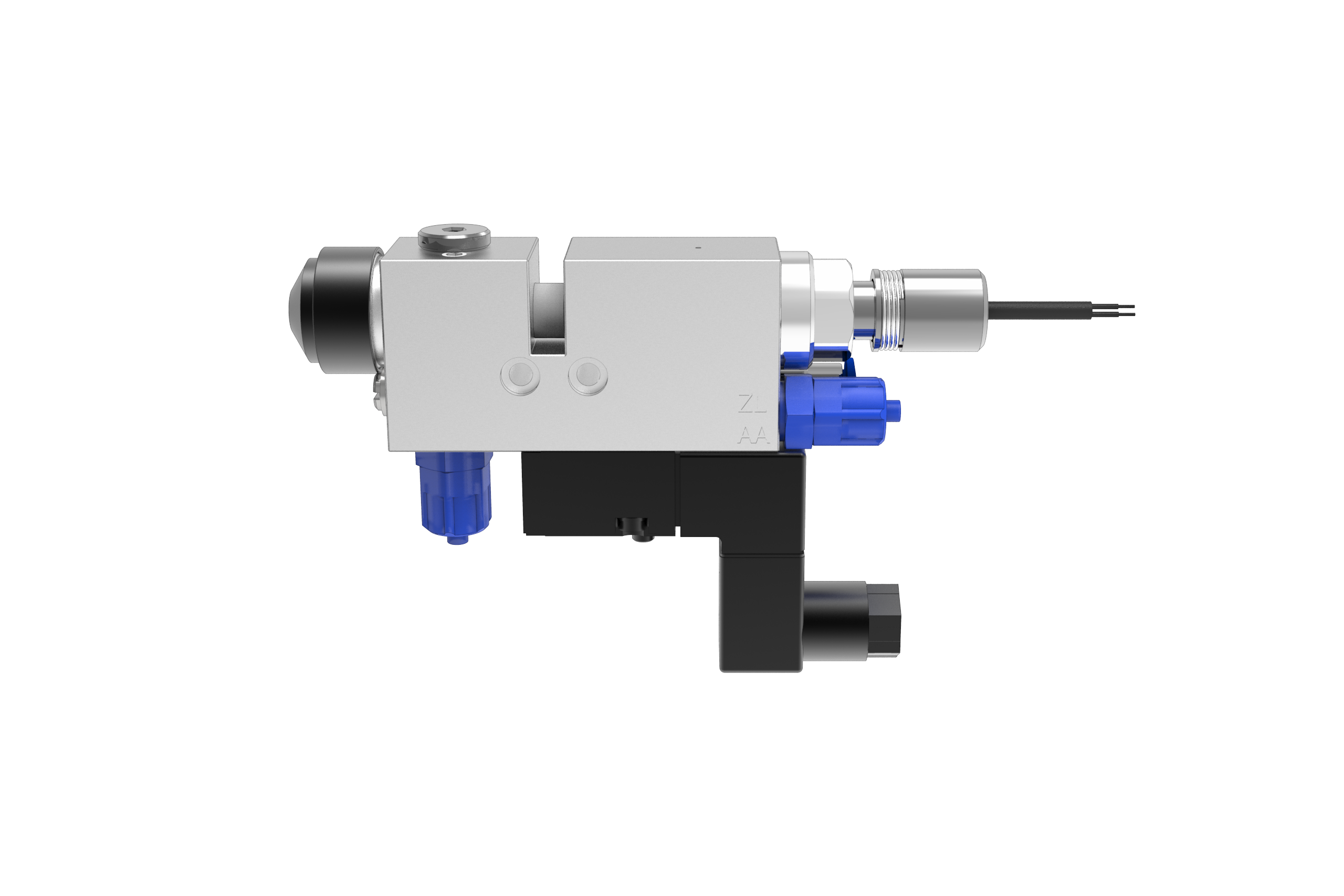

- process pressure: max. 35 [bar]

- control air pressure: min. 5 to 6 [bar]

- atomizer air pressure: 0,5 to 6 [bar]

- process connection (medium): G1/4" incl. hose screw joint 6/4

- process connection (air): hose screw joint 6/4

- dimensions (l x w x h): 132 x 81 x 22 [mm] (incl. magnetic valve)

- weight: 0,525 [kg]

- nozzle & needle: optionally hardened (kolsterised)