Smart solutions for automated conveying, dosing and application processes

10 Sept 2019, 07:00:00

Germersheim, 10.09.2019: At Motek 2019, Walther Systemtechnik GmbH will be presenting intelligent systems for material preparation with optimum practical benefits.

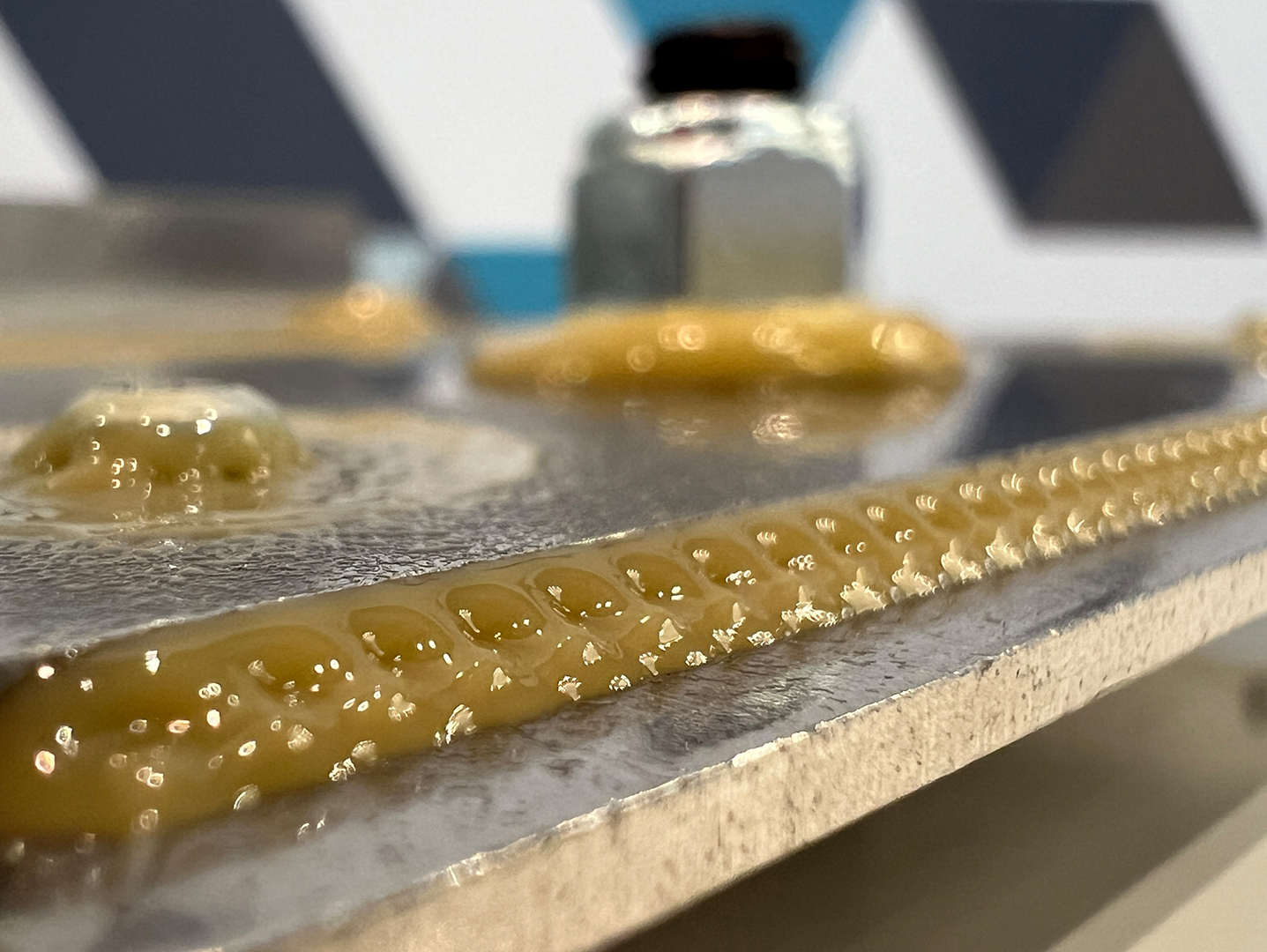

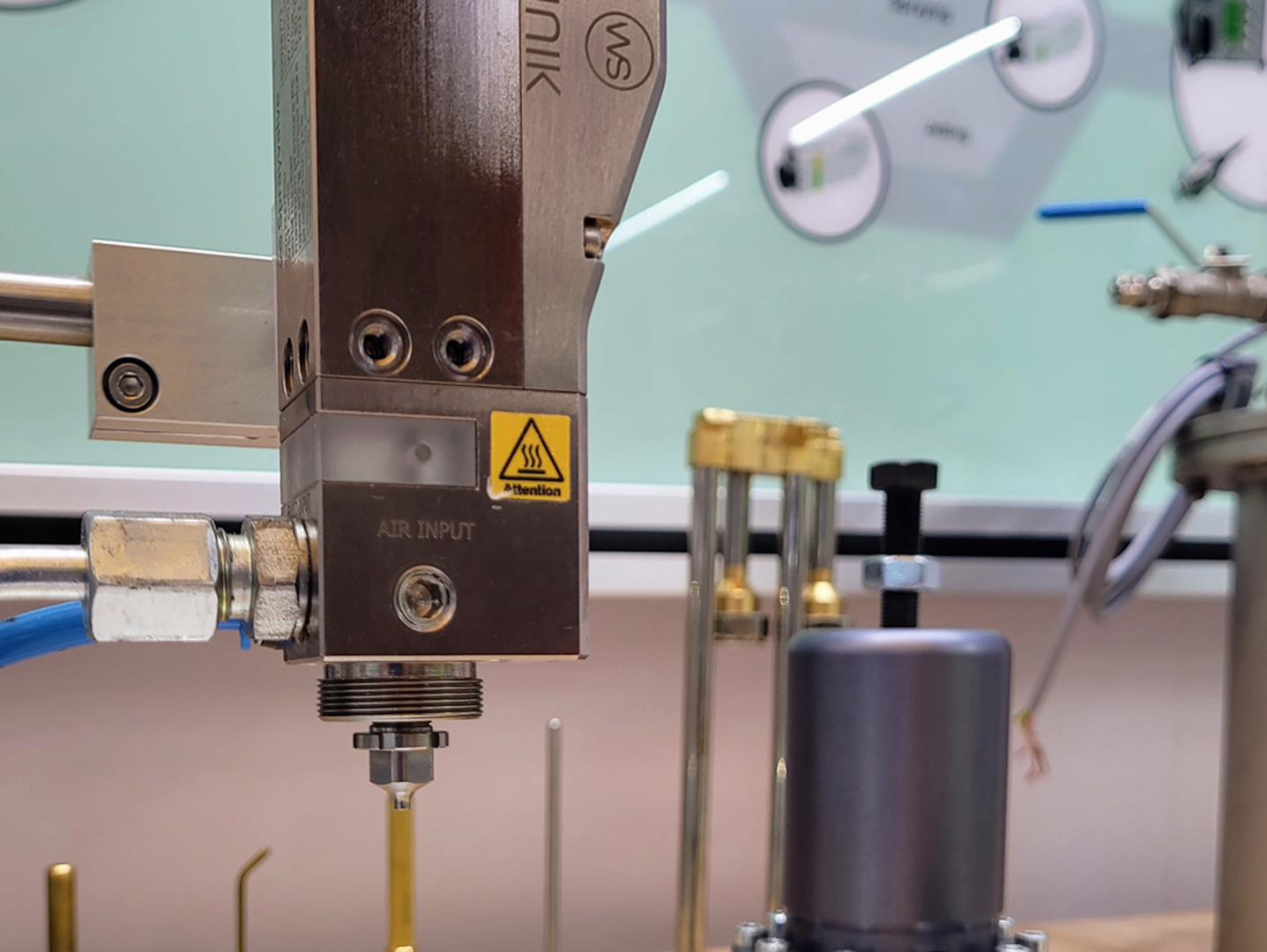

Whether material preparation systems with intelligent analysis functions, extremely compact modular components or cobot-dominated application processes - at Motek 2019, Walther Systemtechnik GmbH will be presenting innovative new products that measurably increase output and can be easily integrated into existing production chains.

The Germersheim-based company is increasingly relying on intelligent solutions and digitalised products to avoid or identify production obstacles. This is also reflected in the new product portfolio.

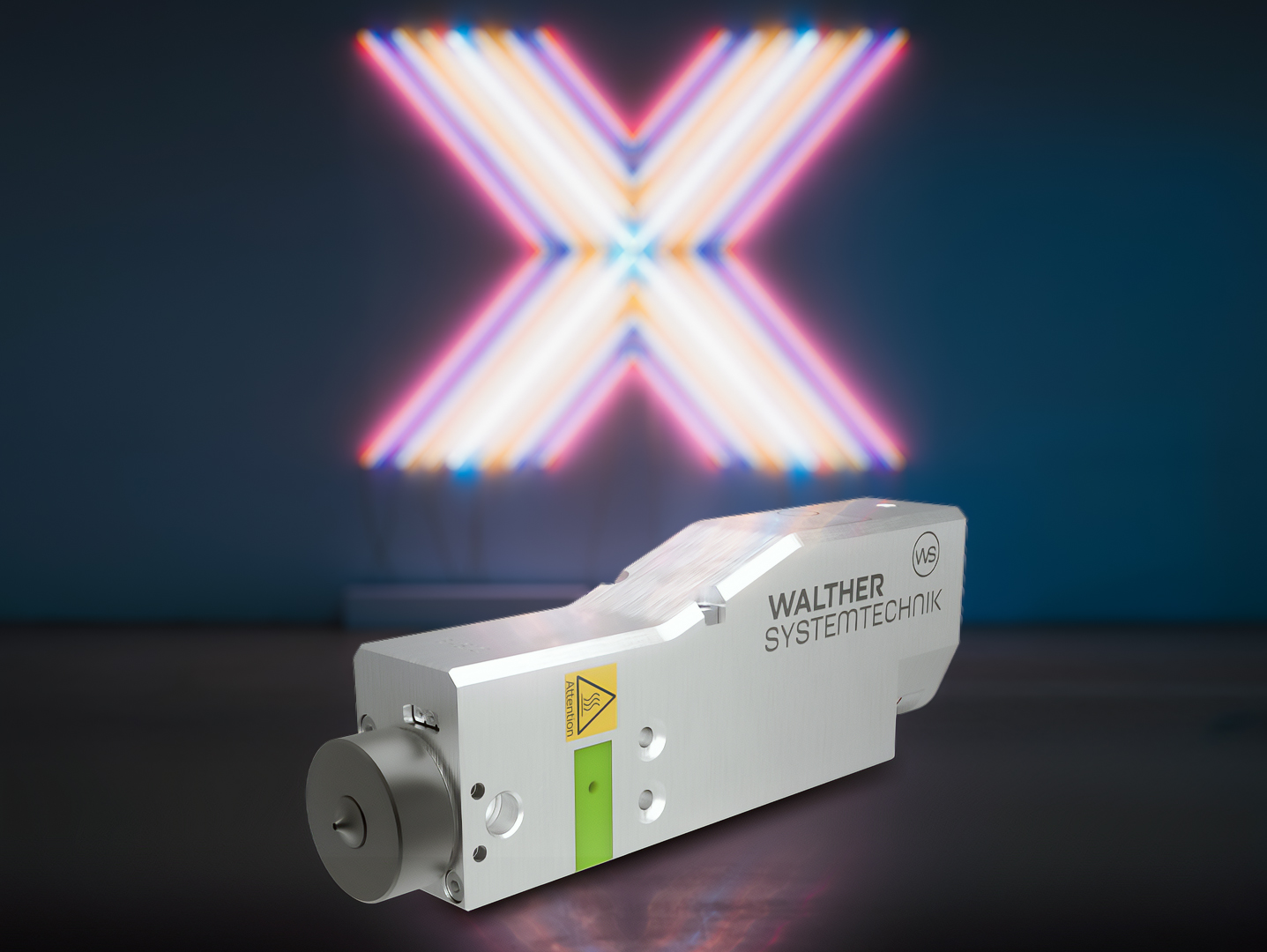

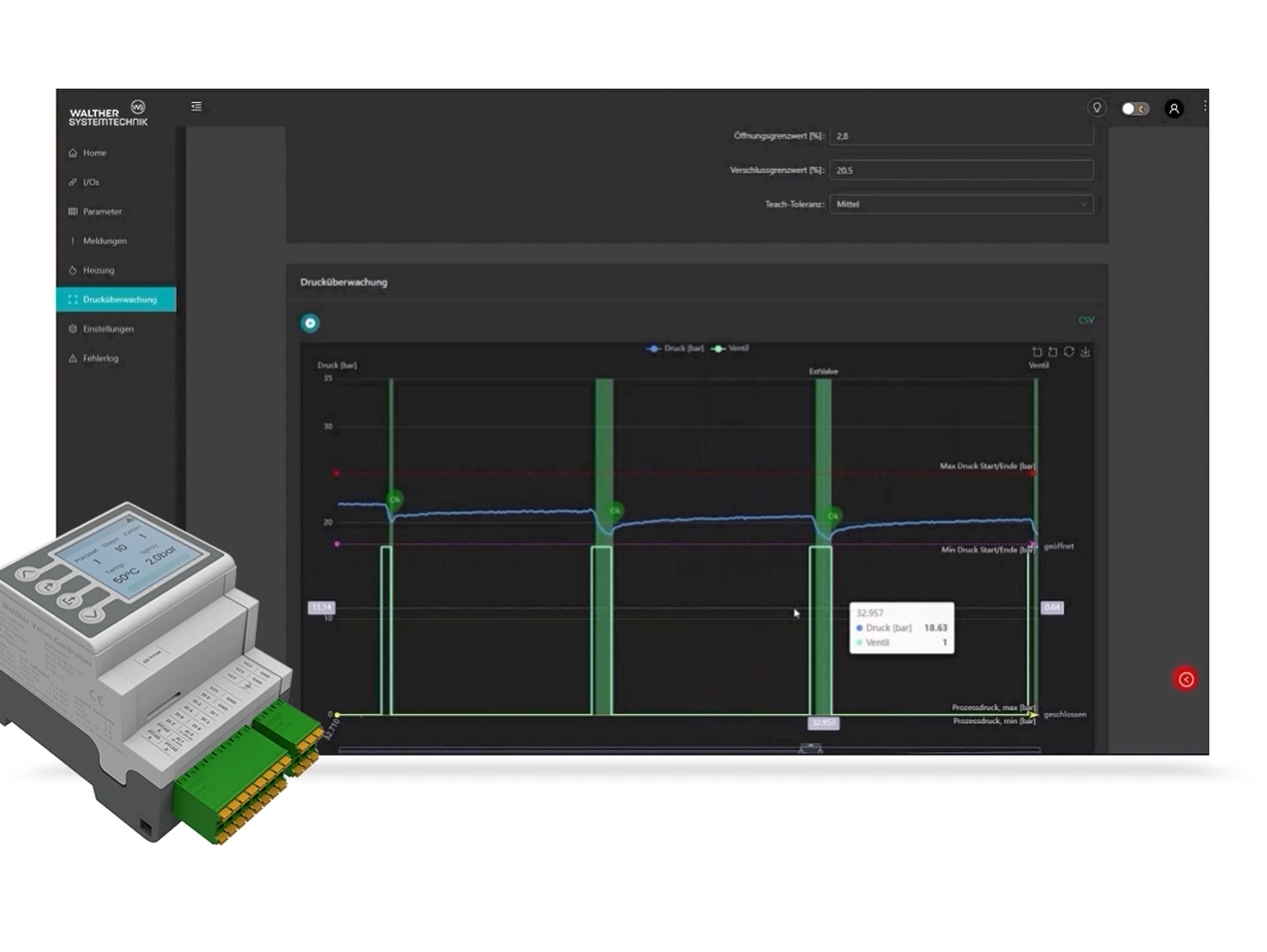

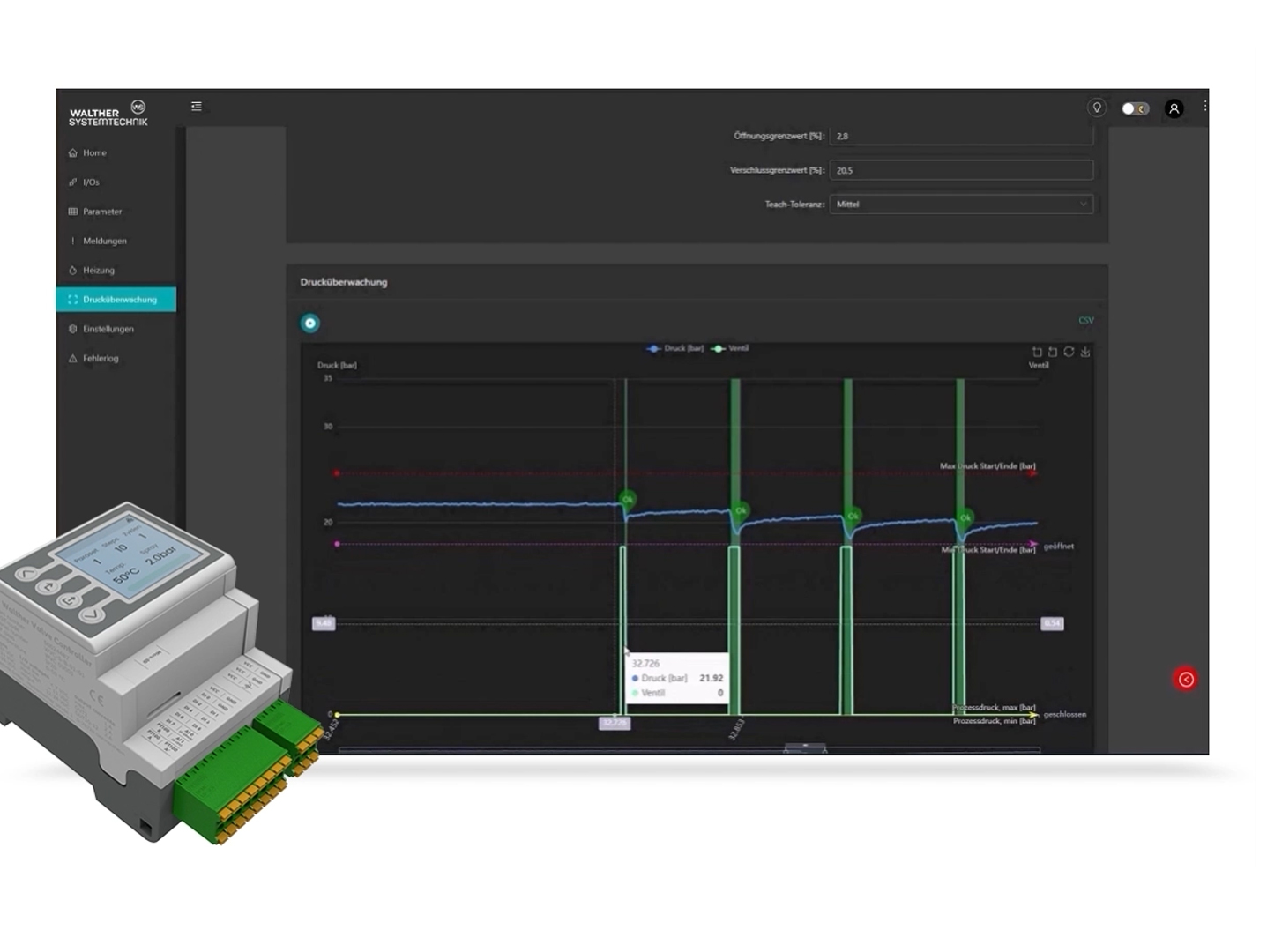

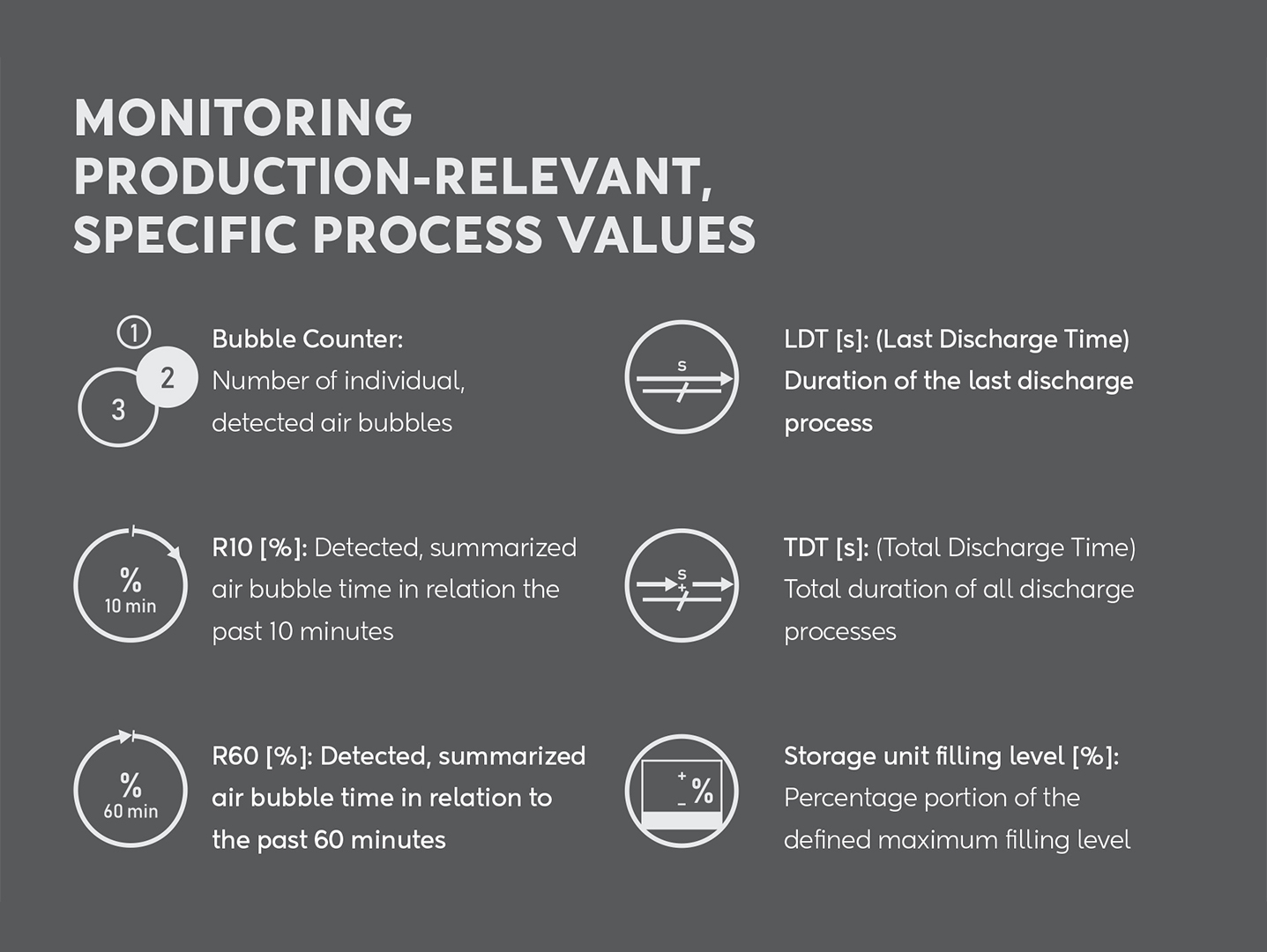

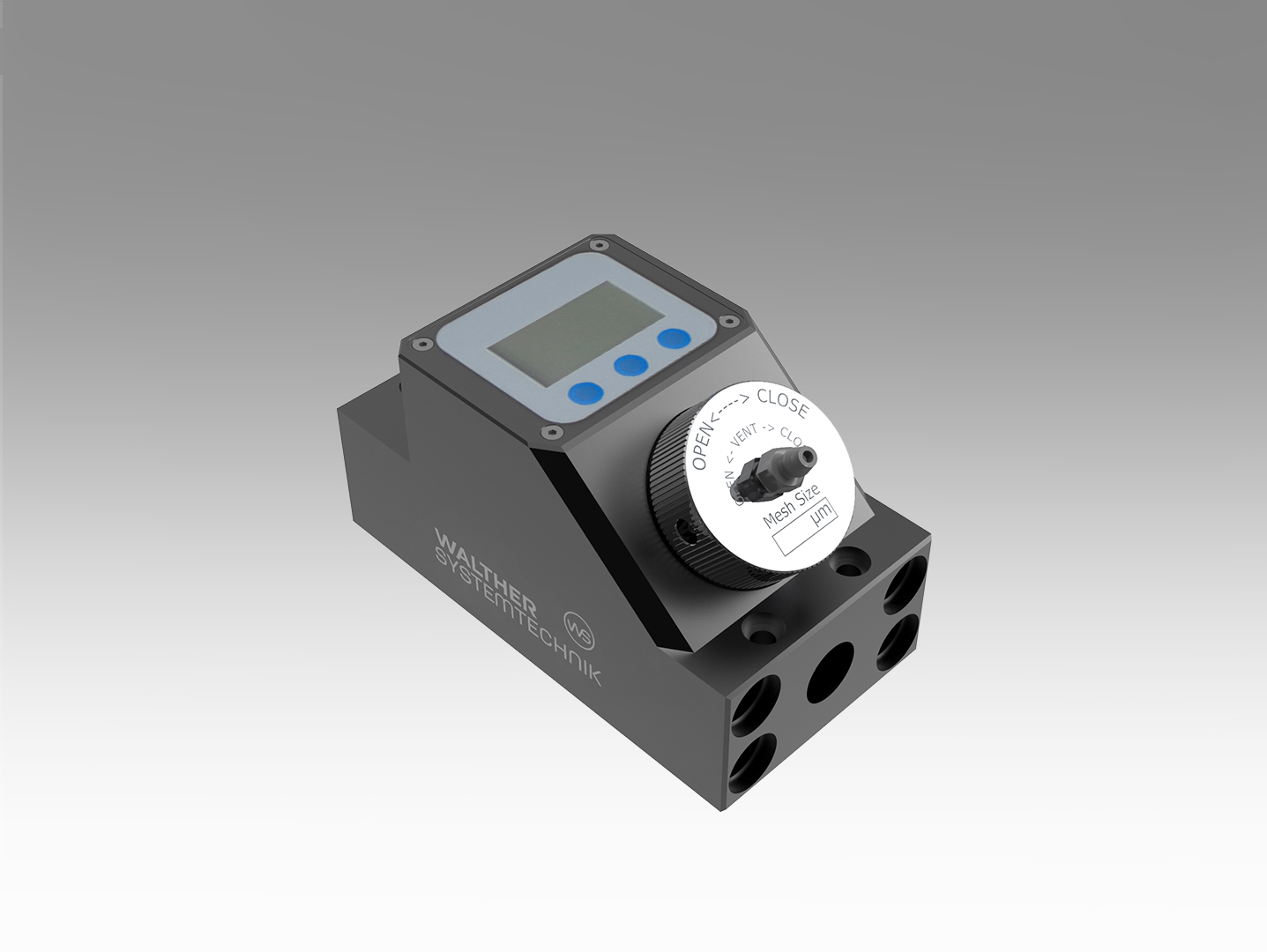

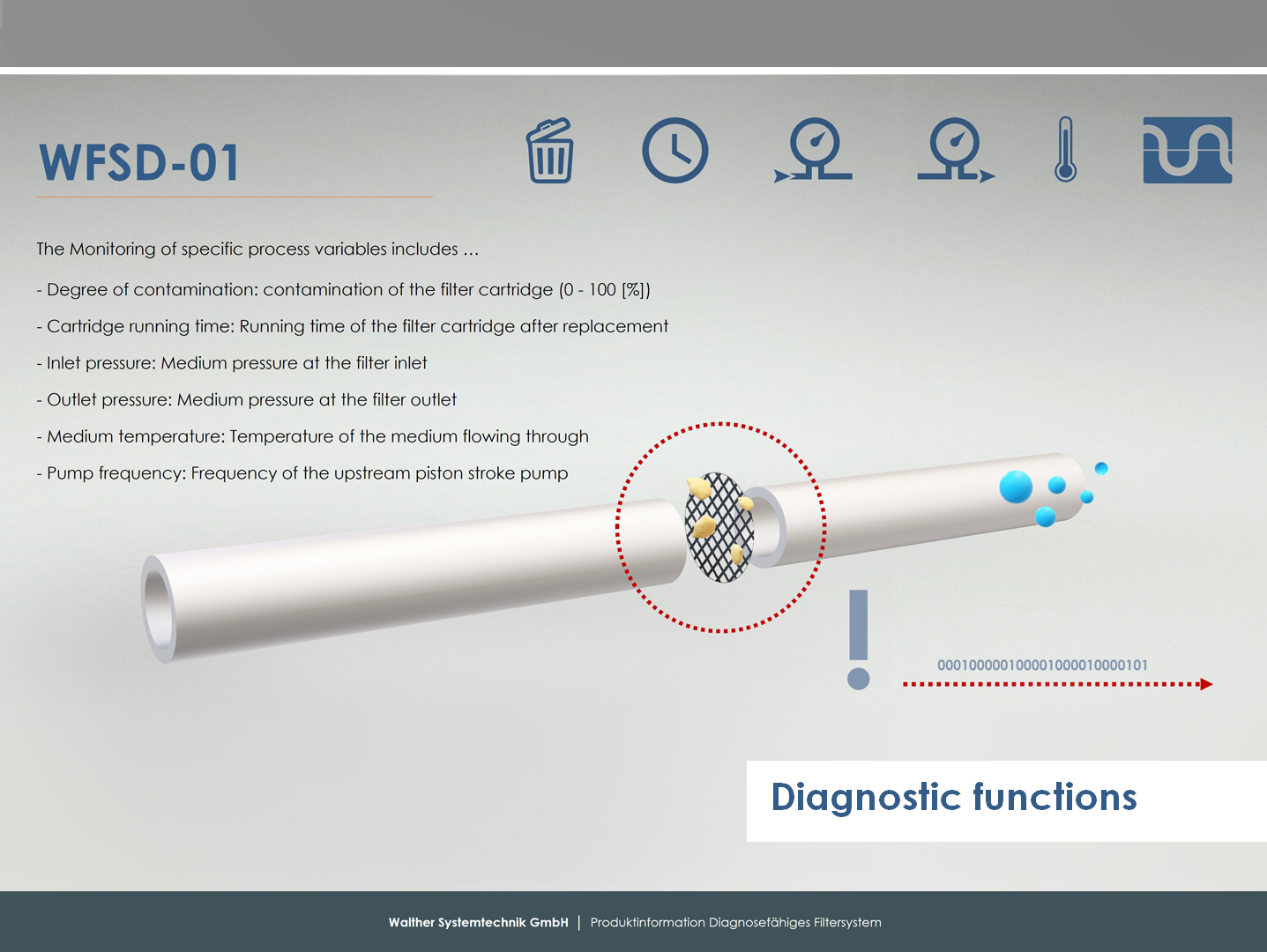

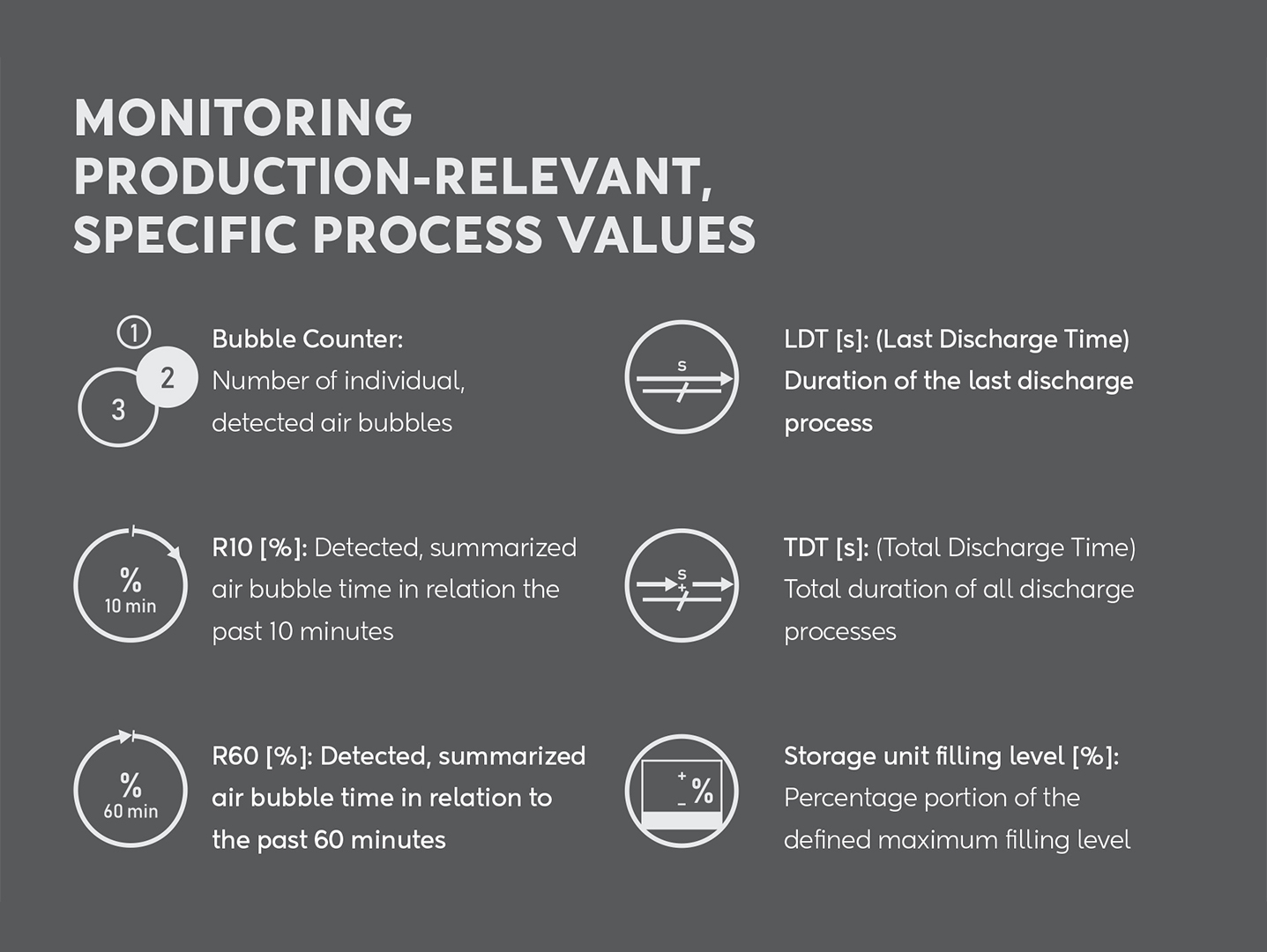

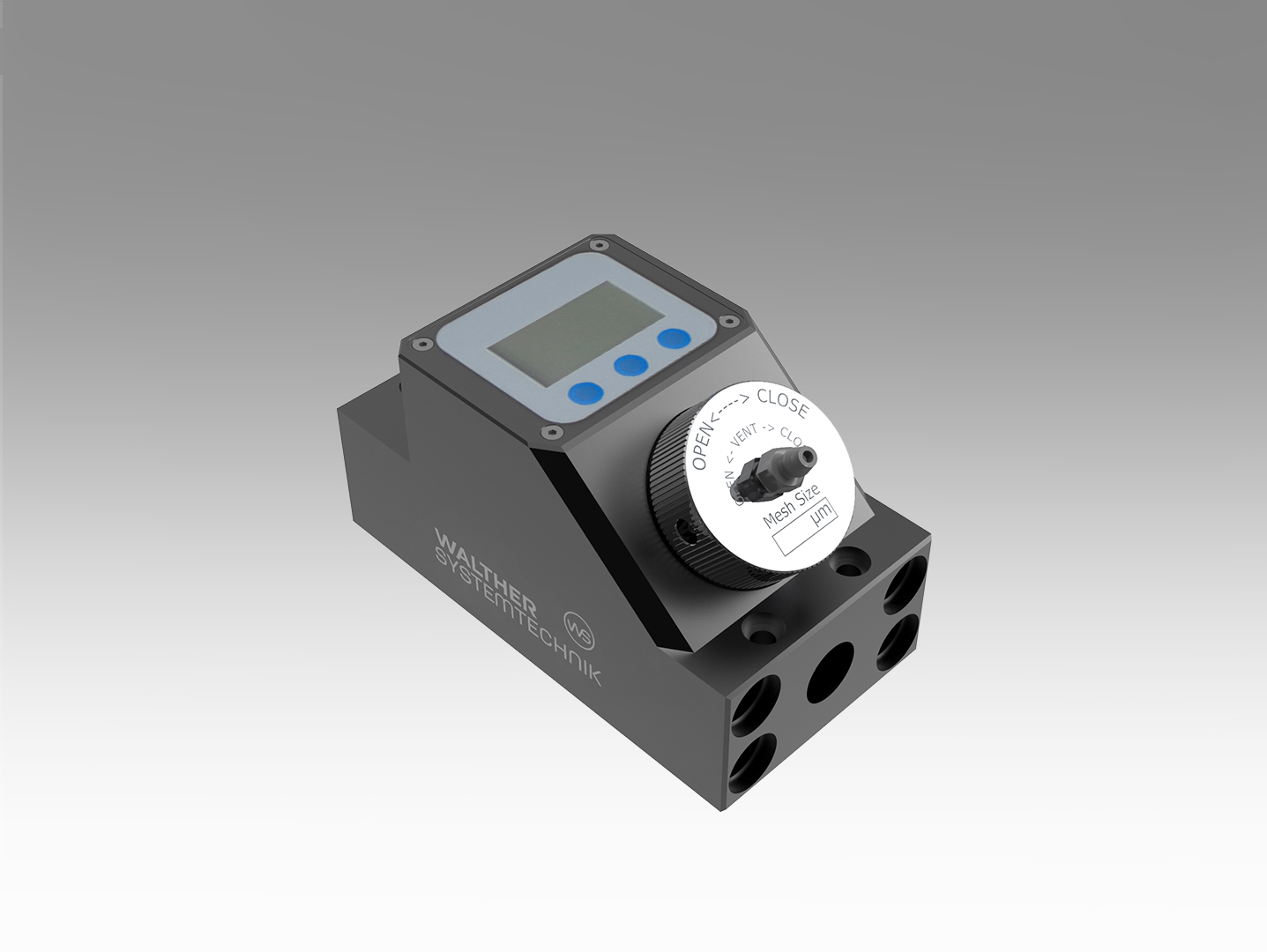

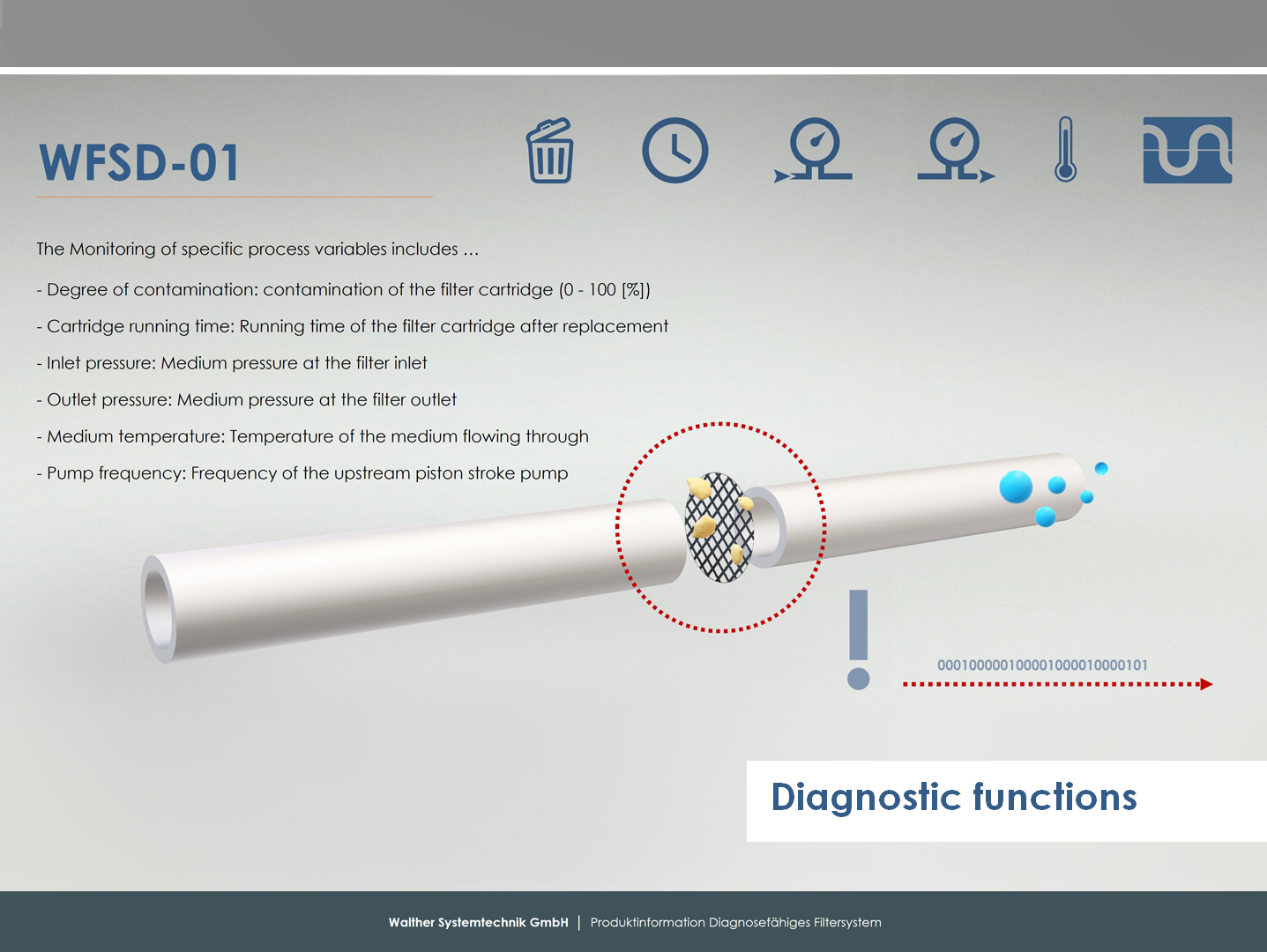

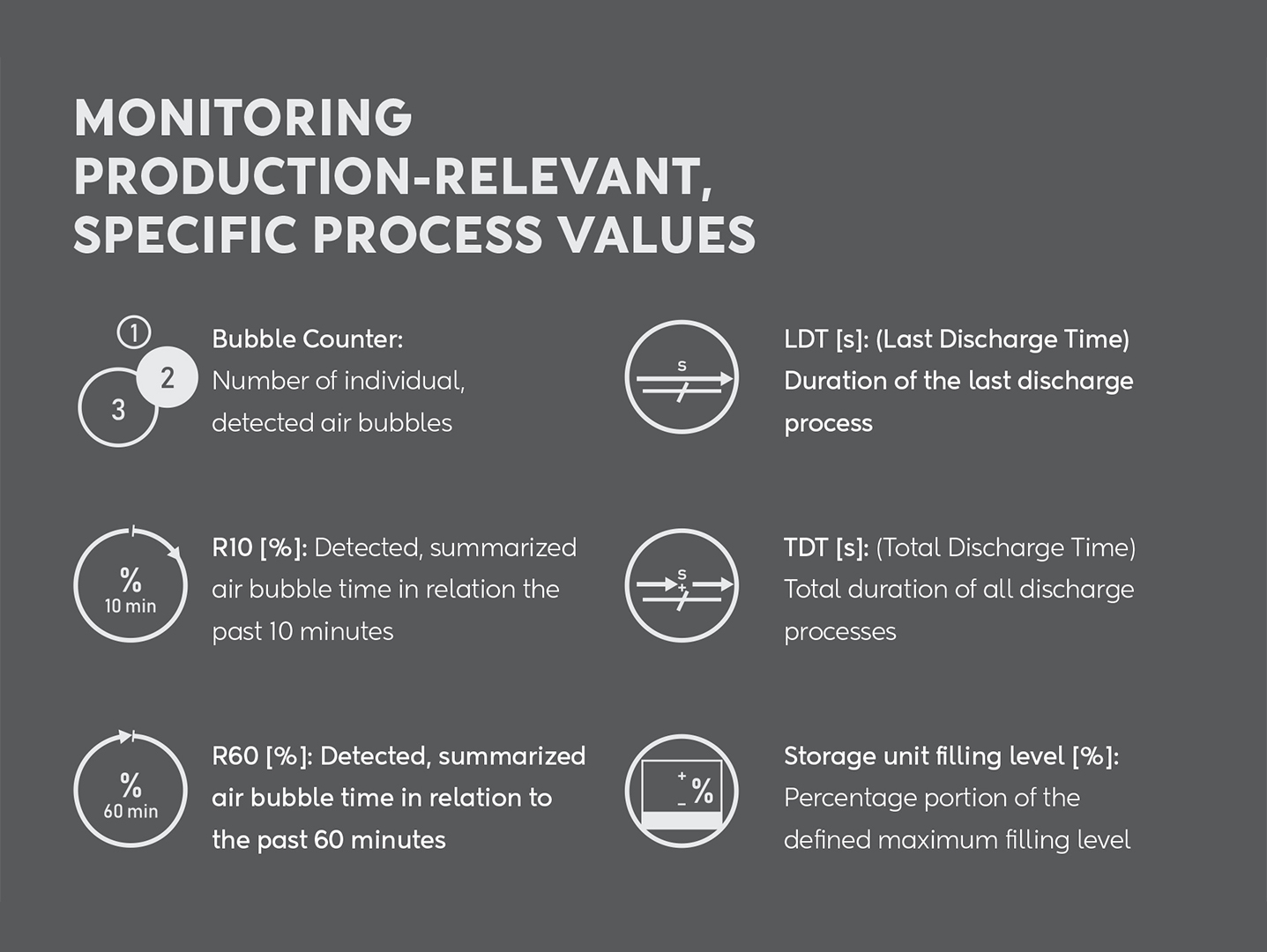

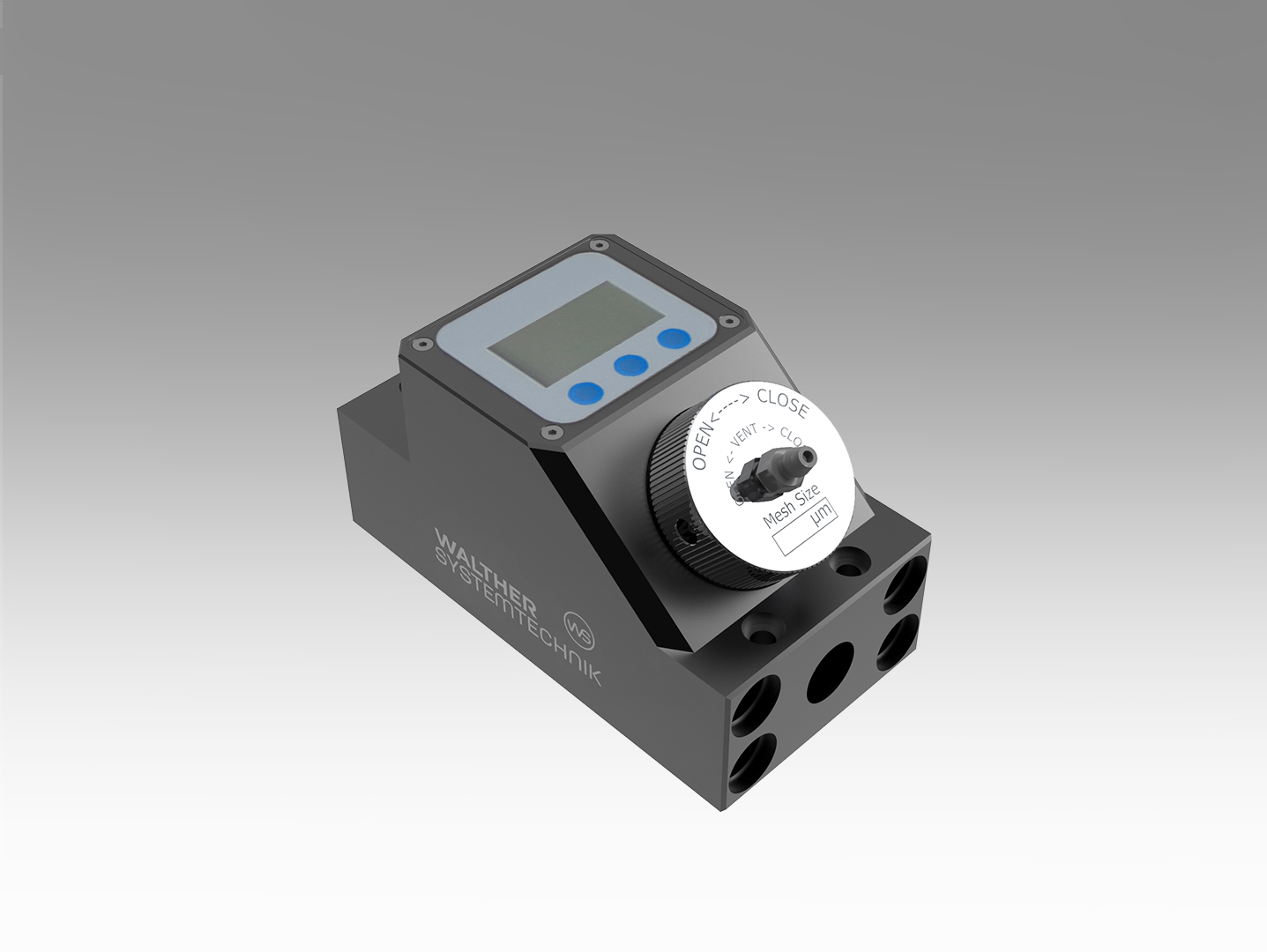

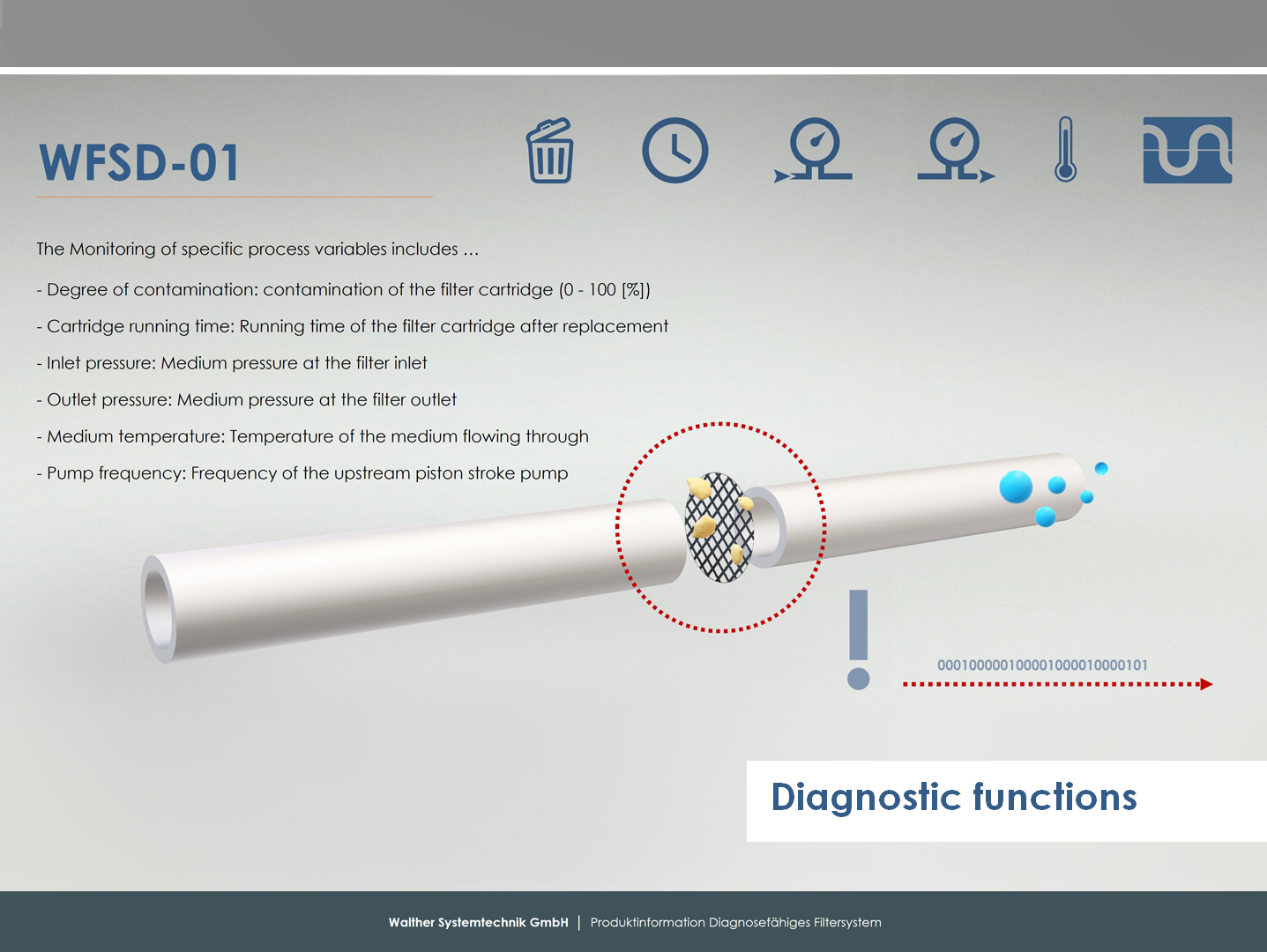

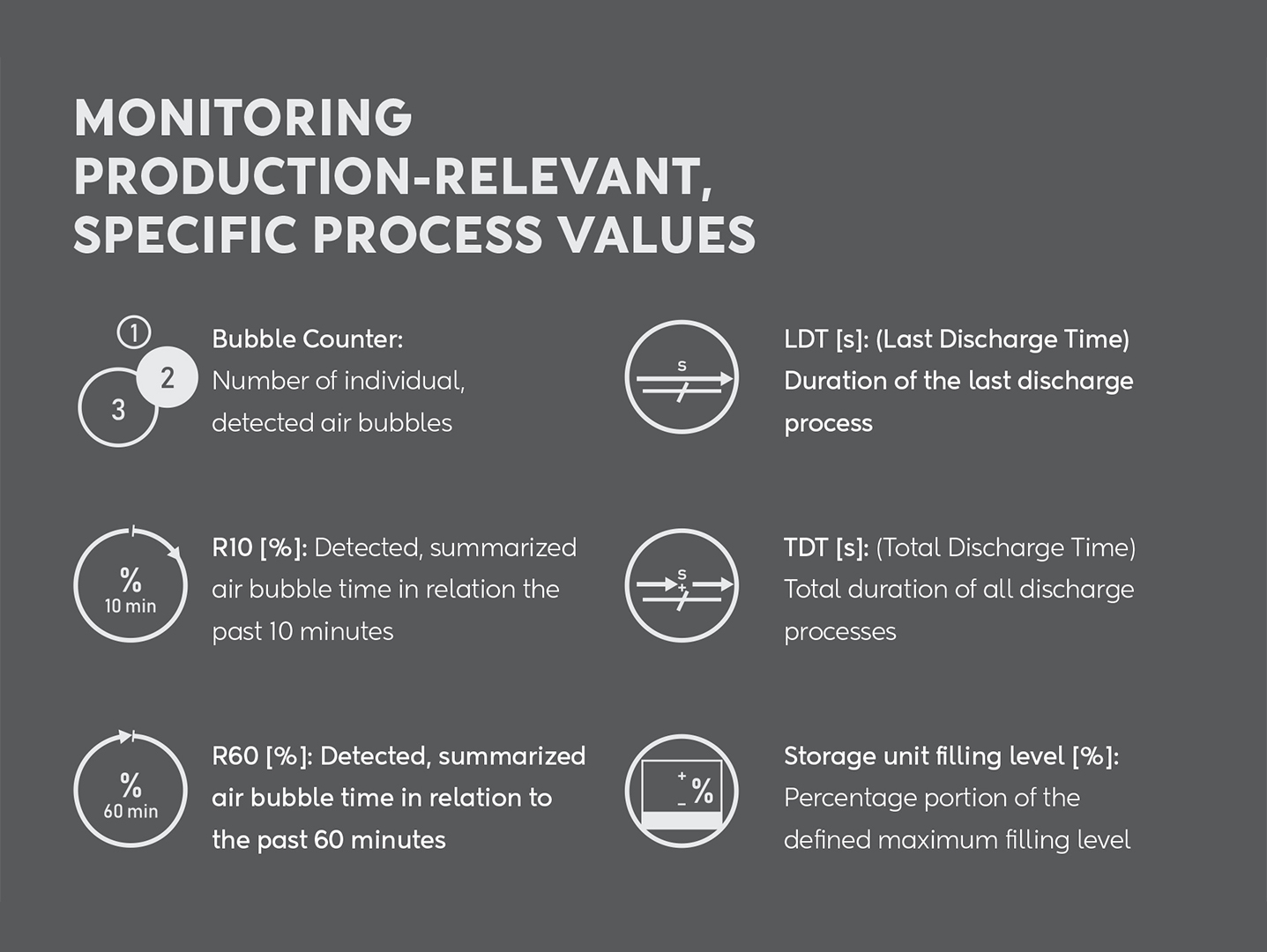

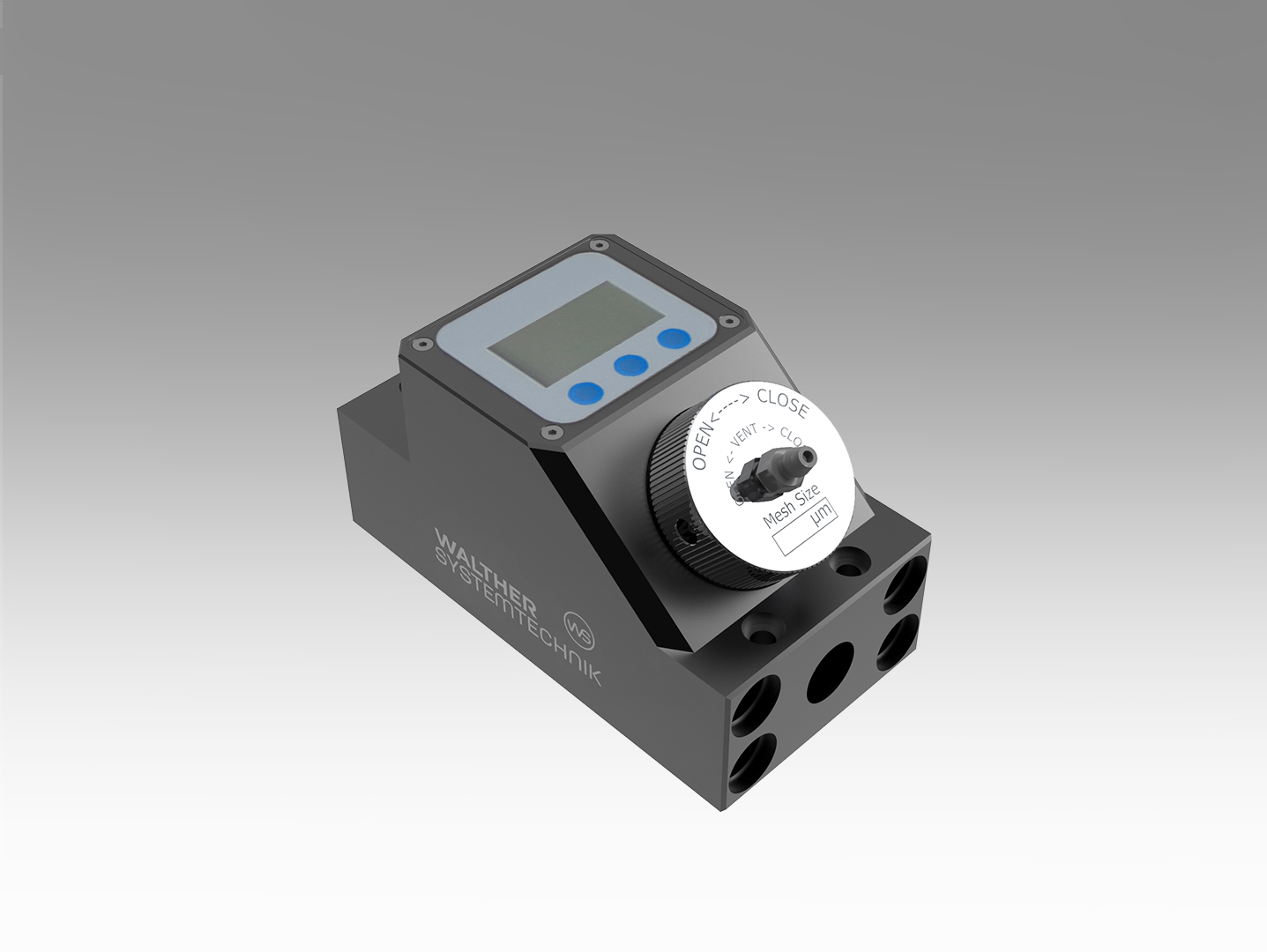

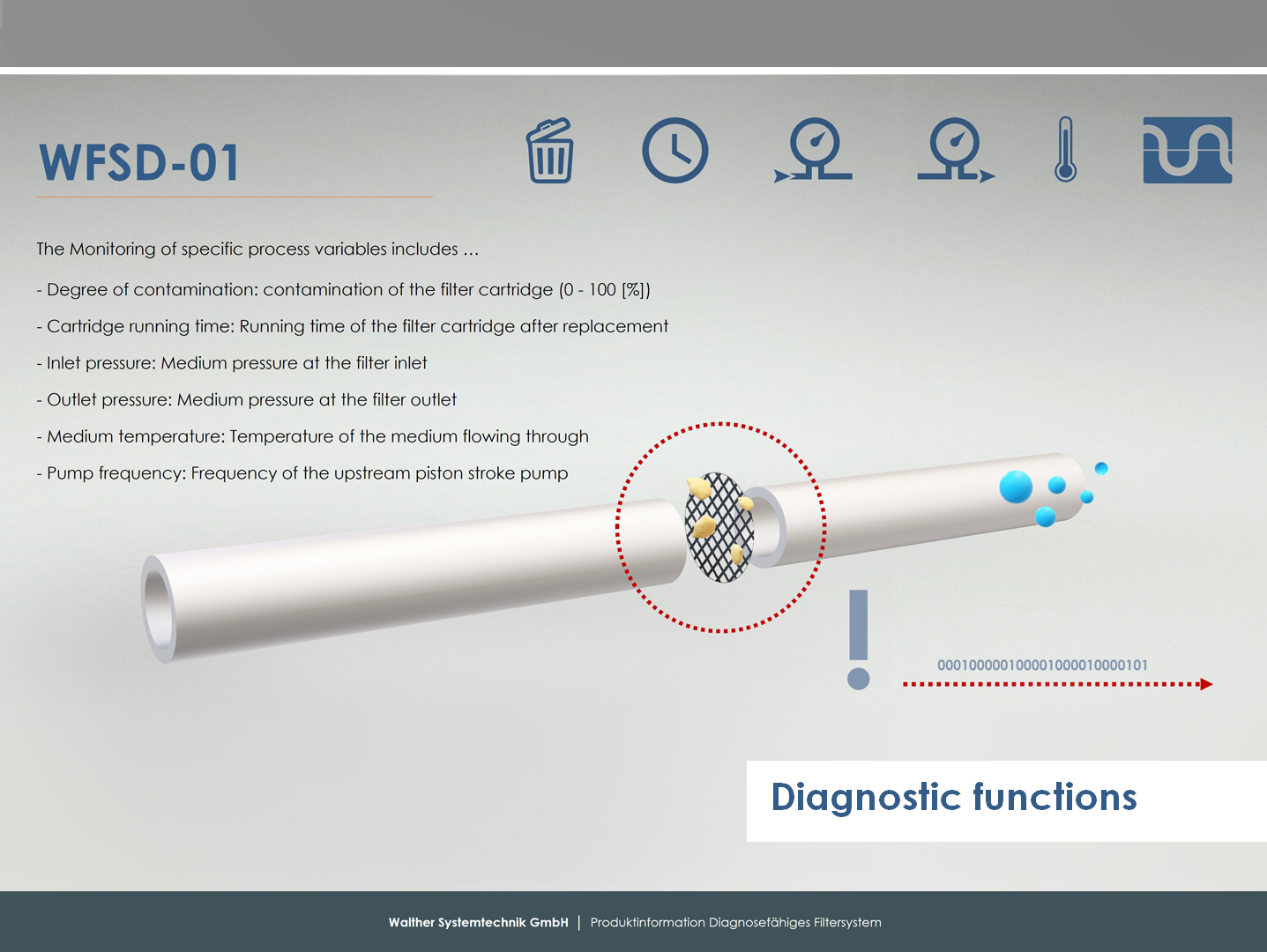

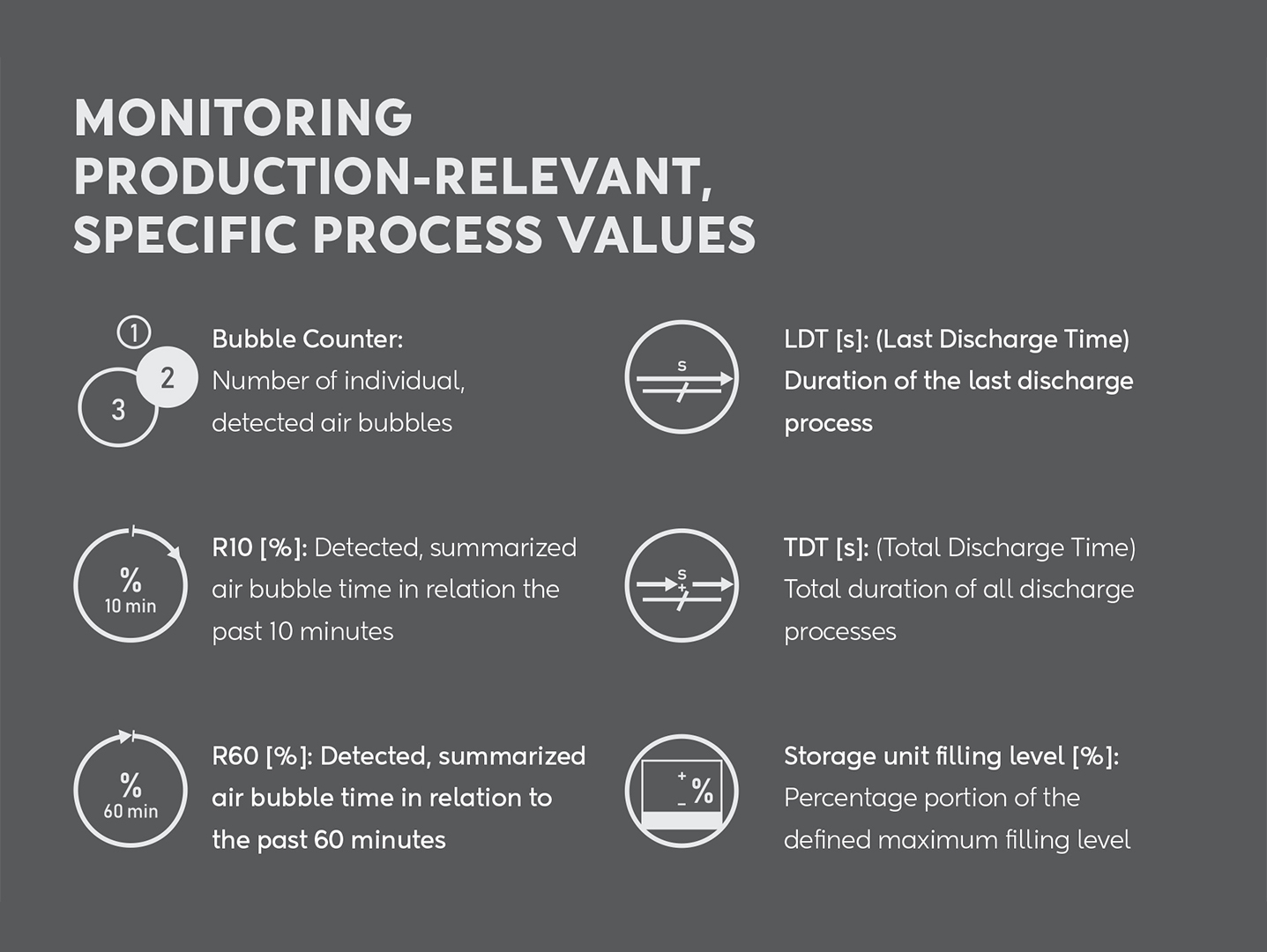

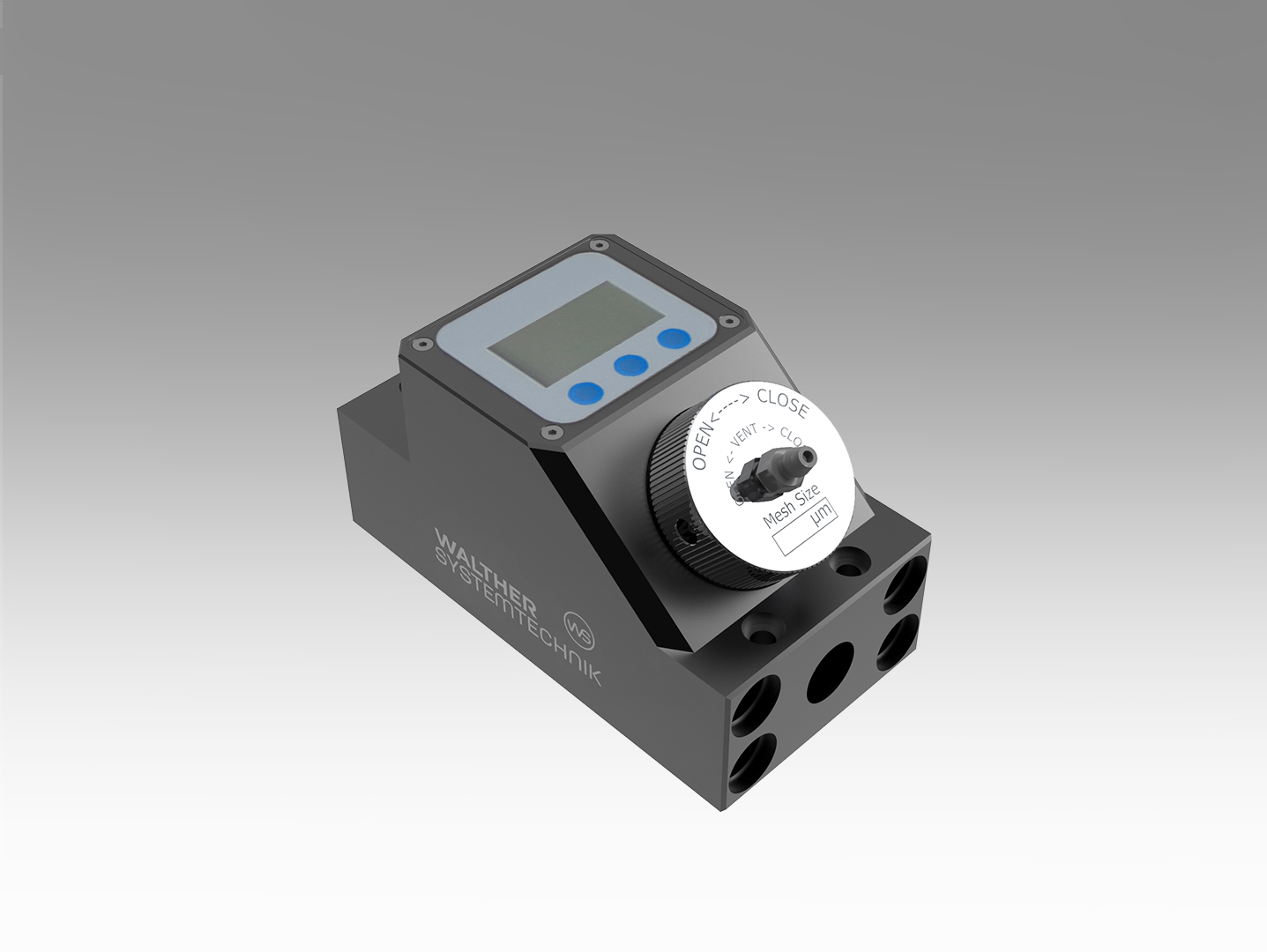

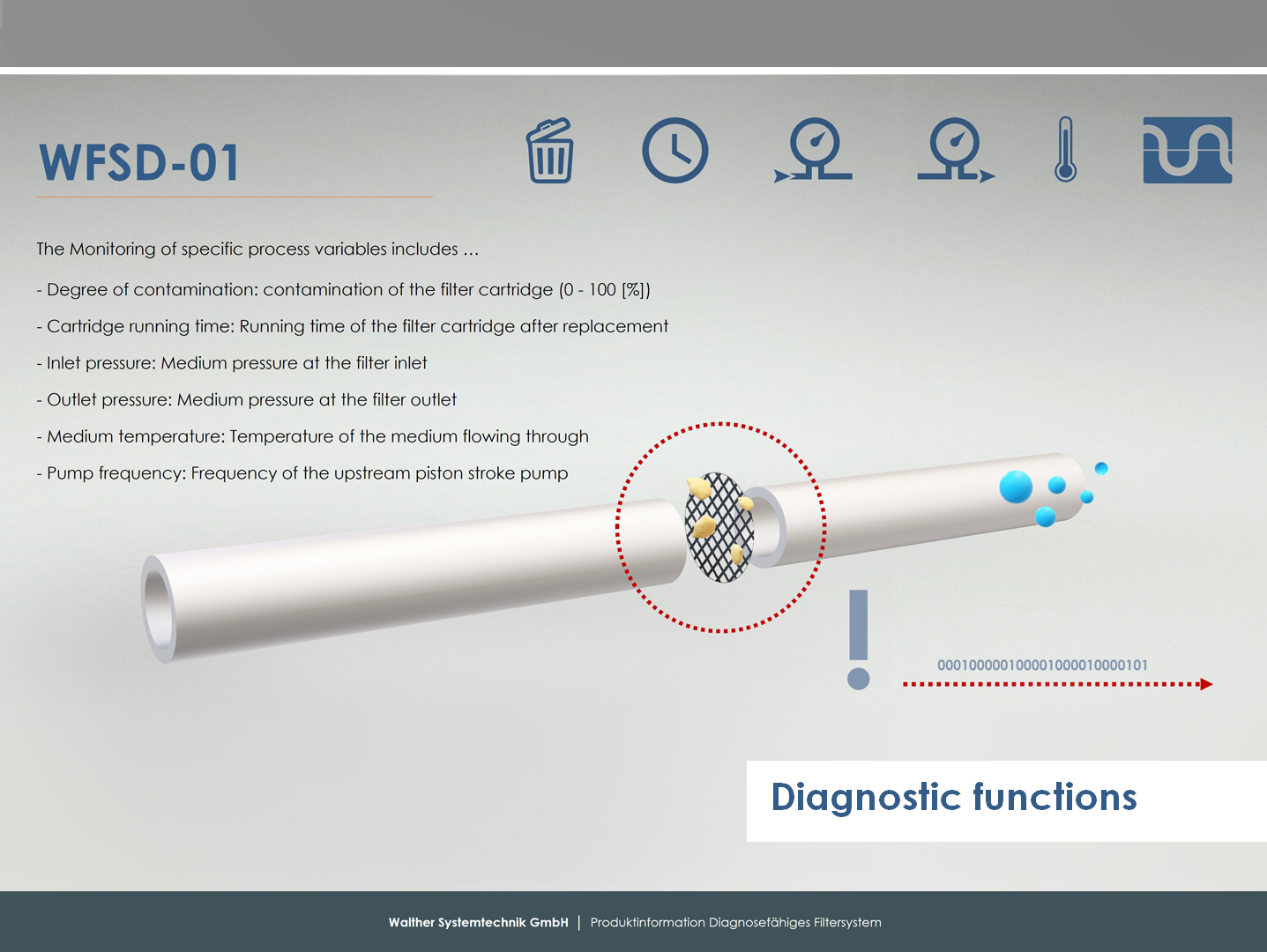

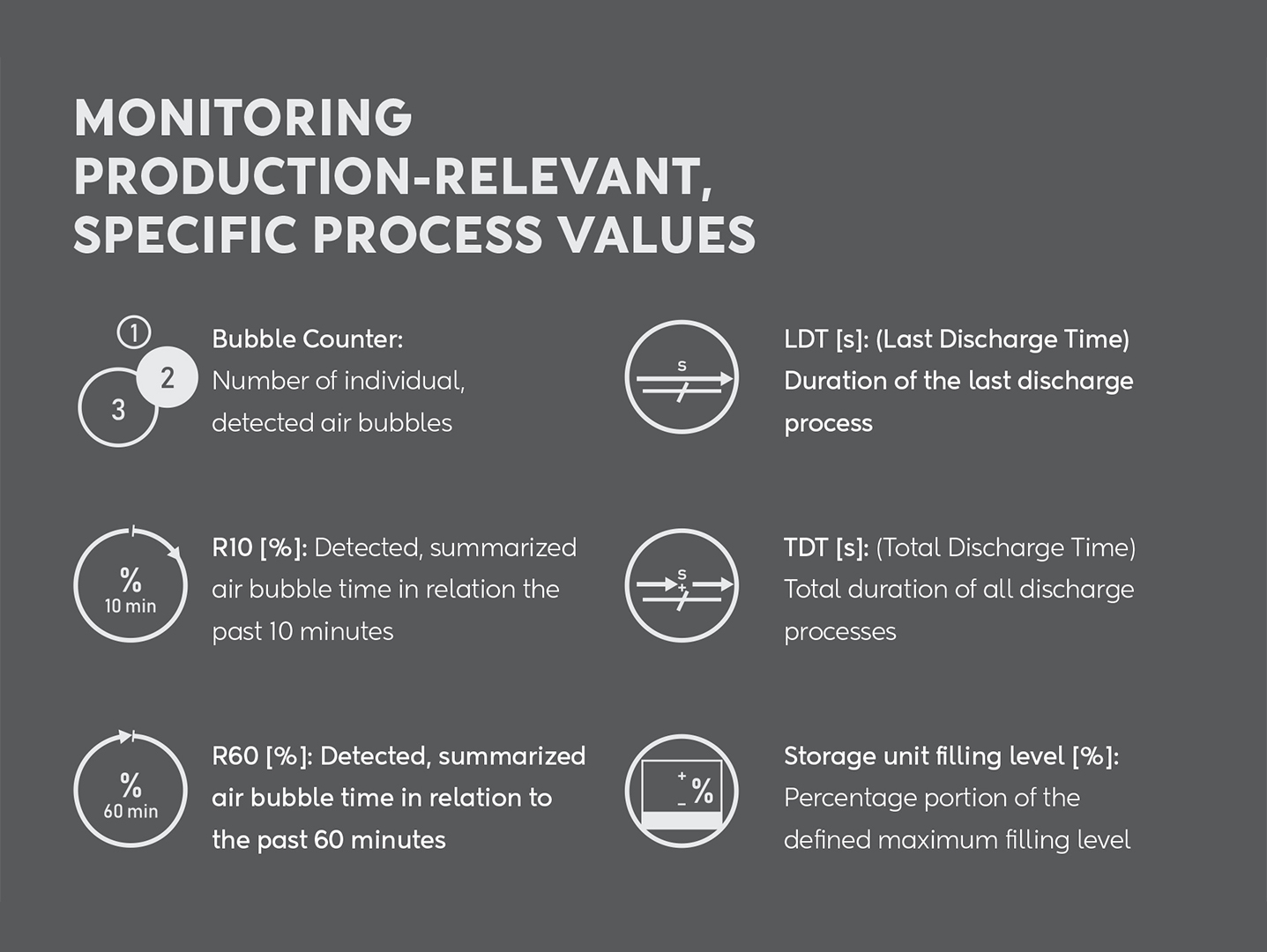

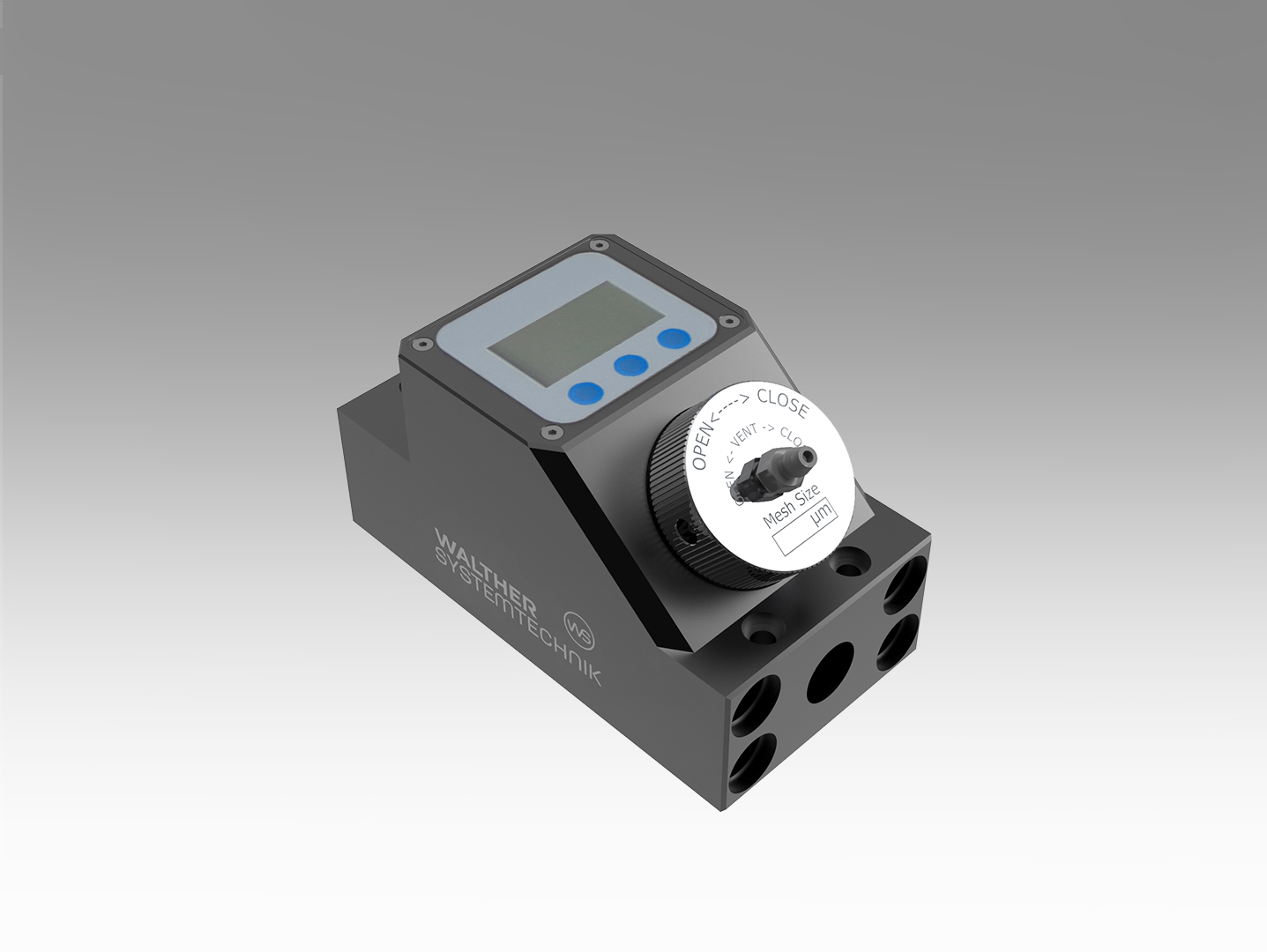

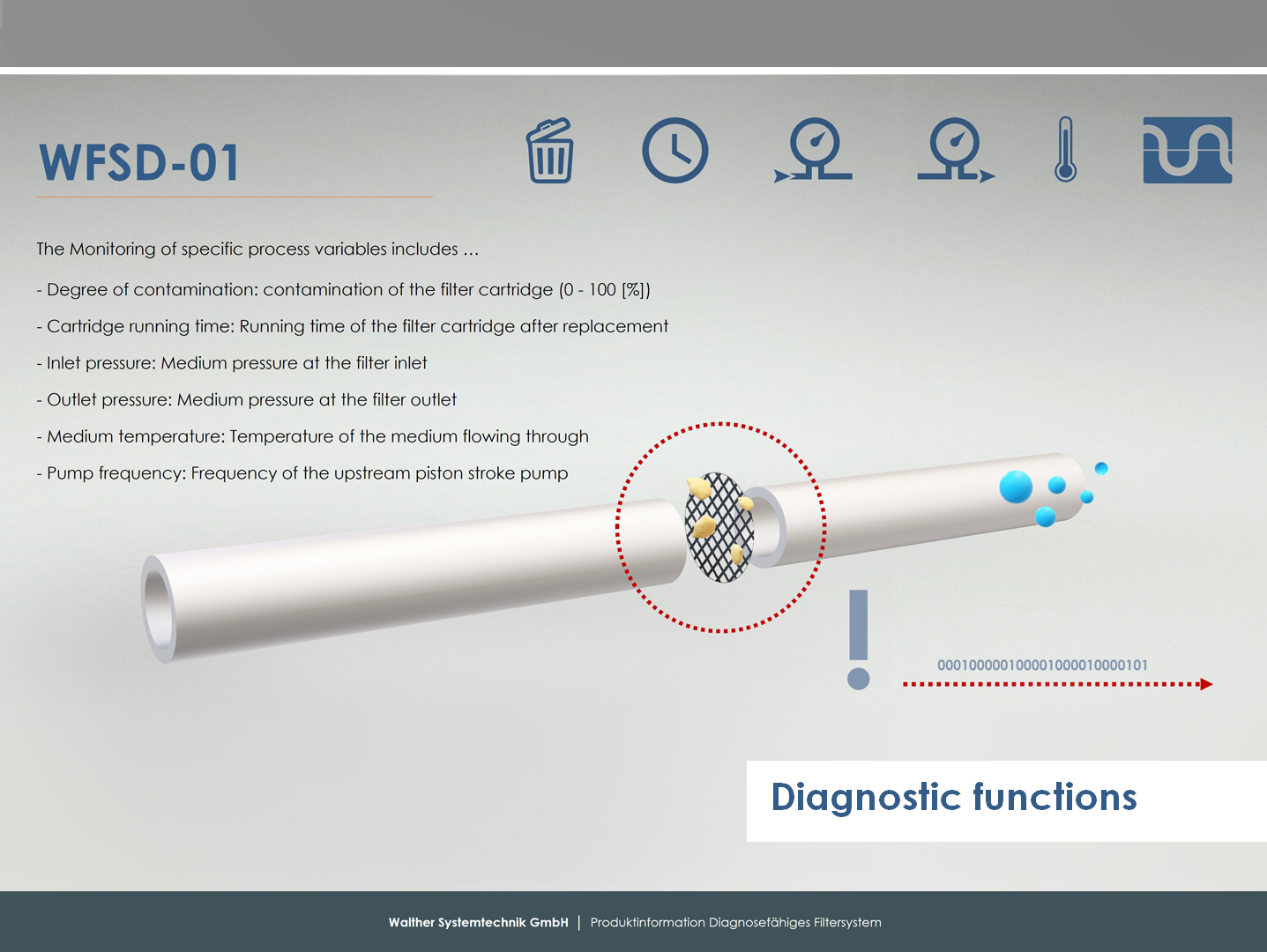

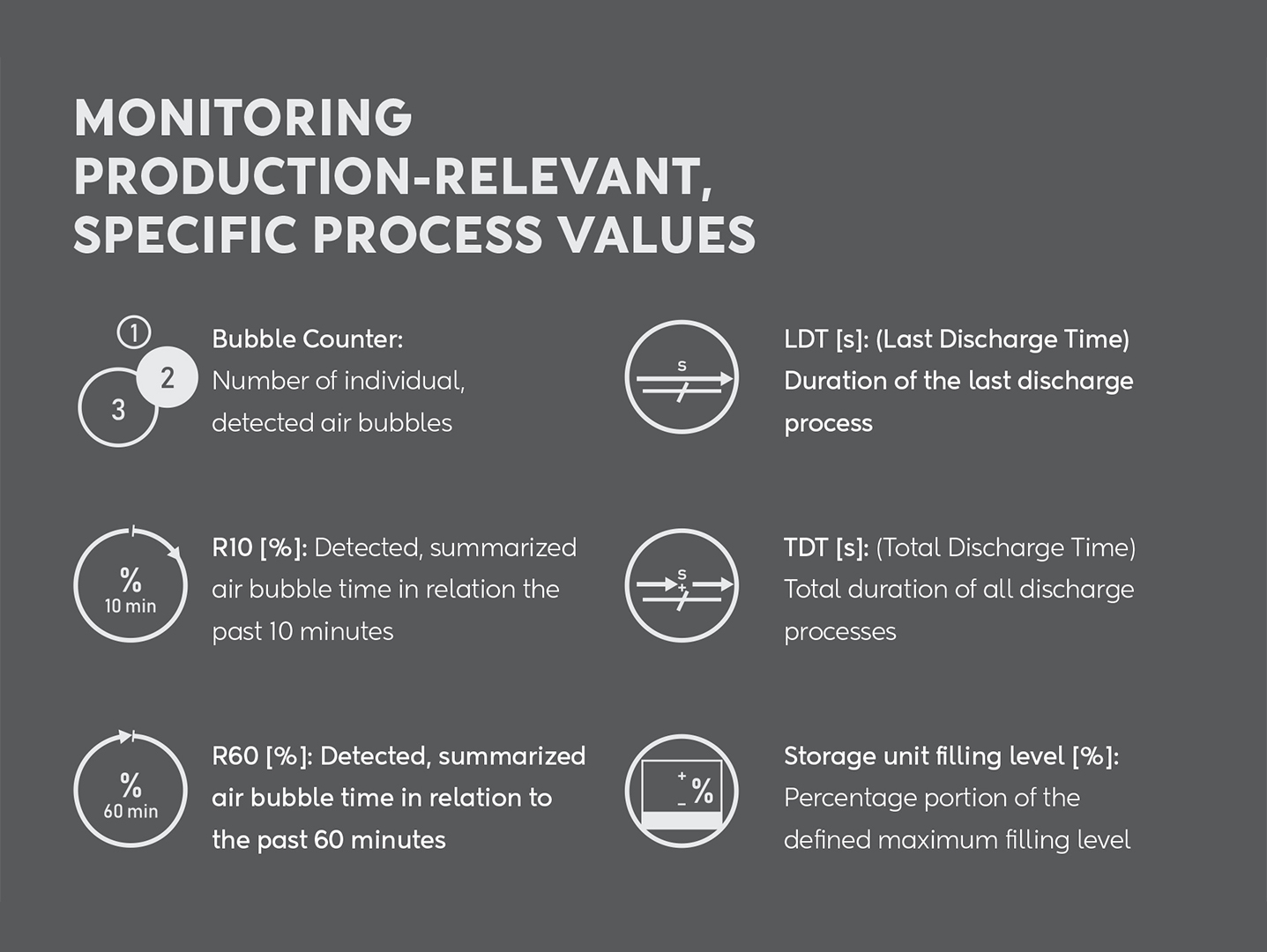

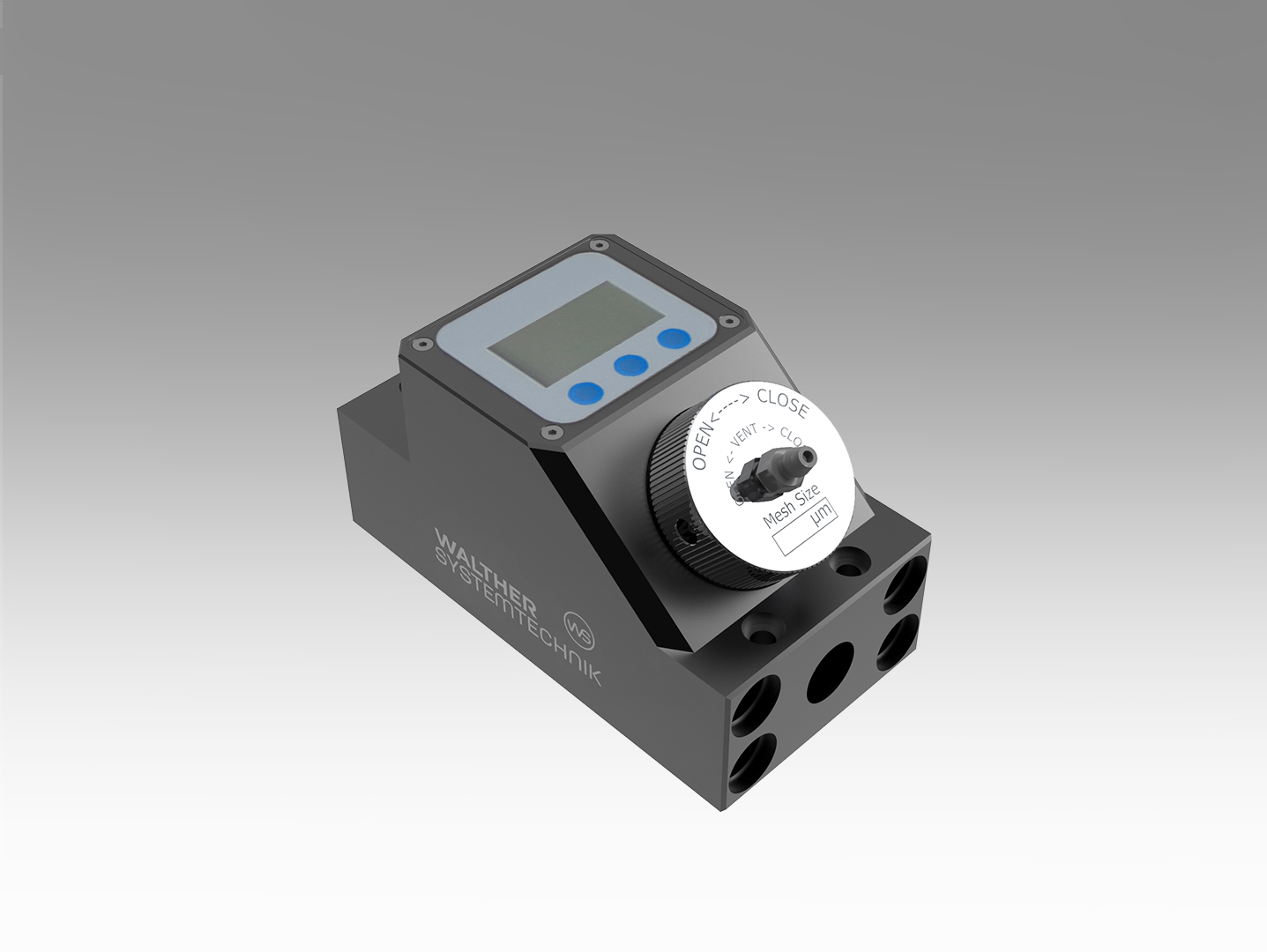

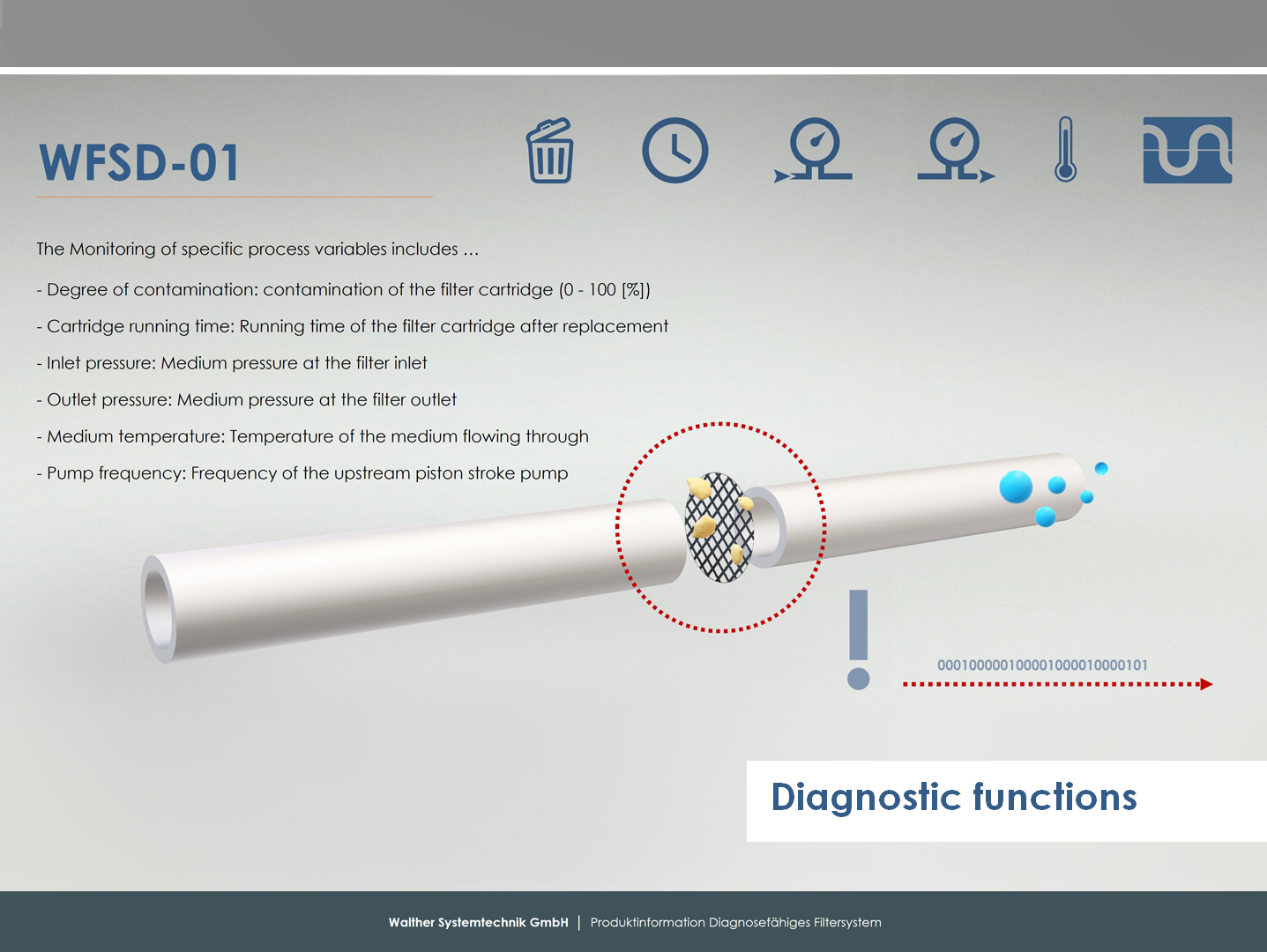

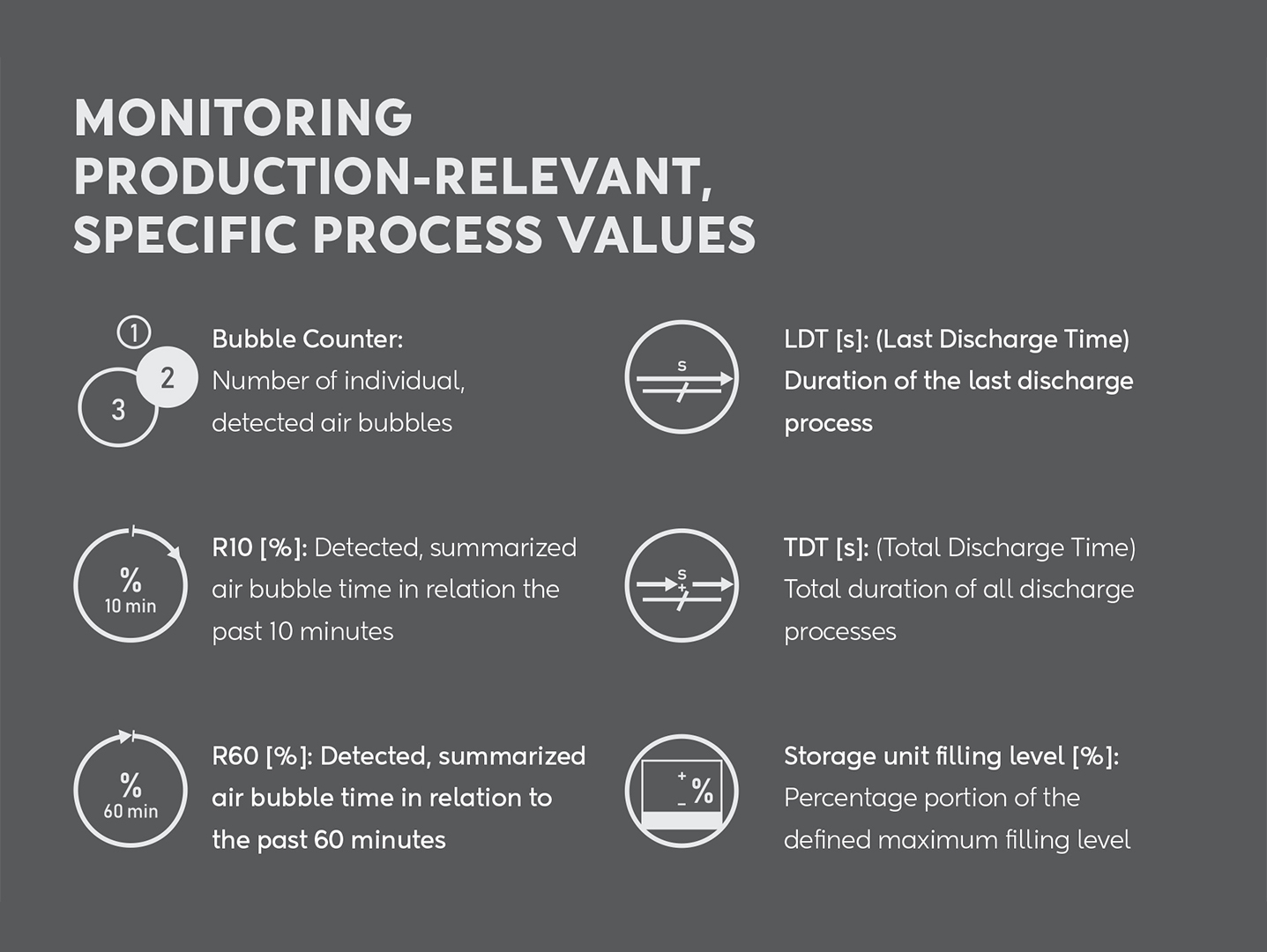

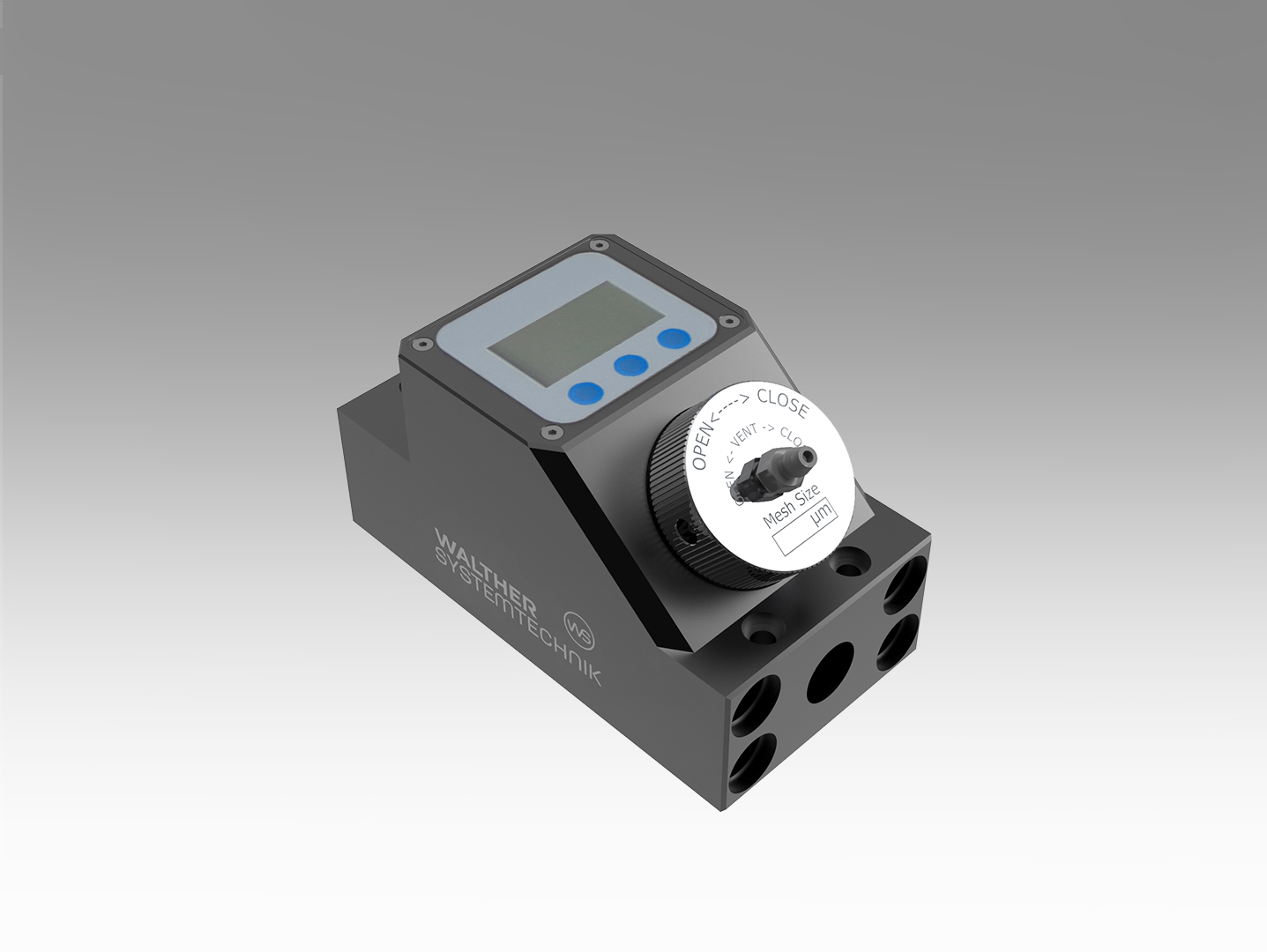

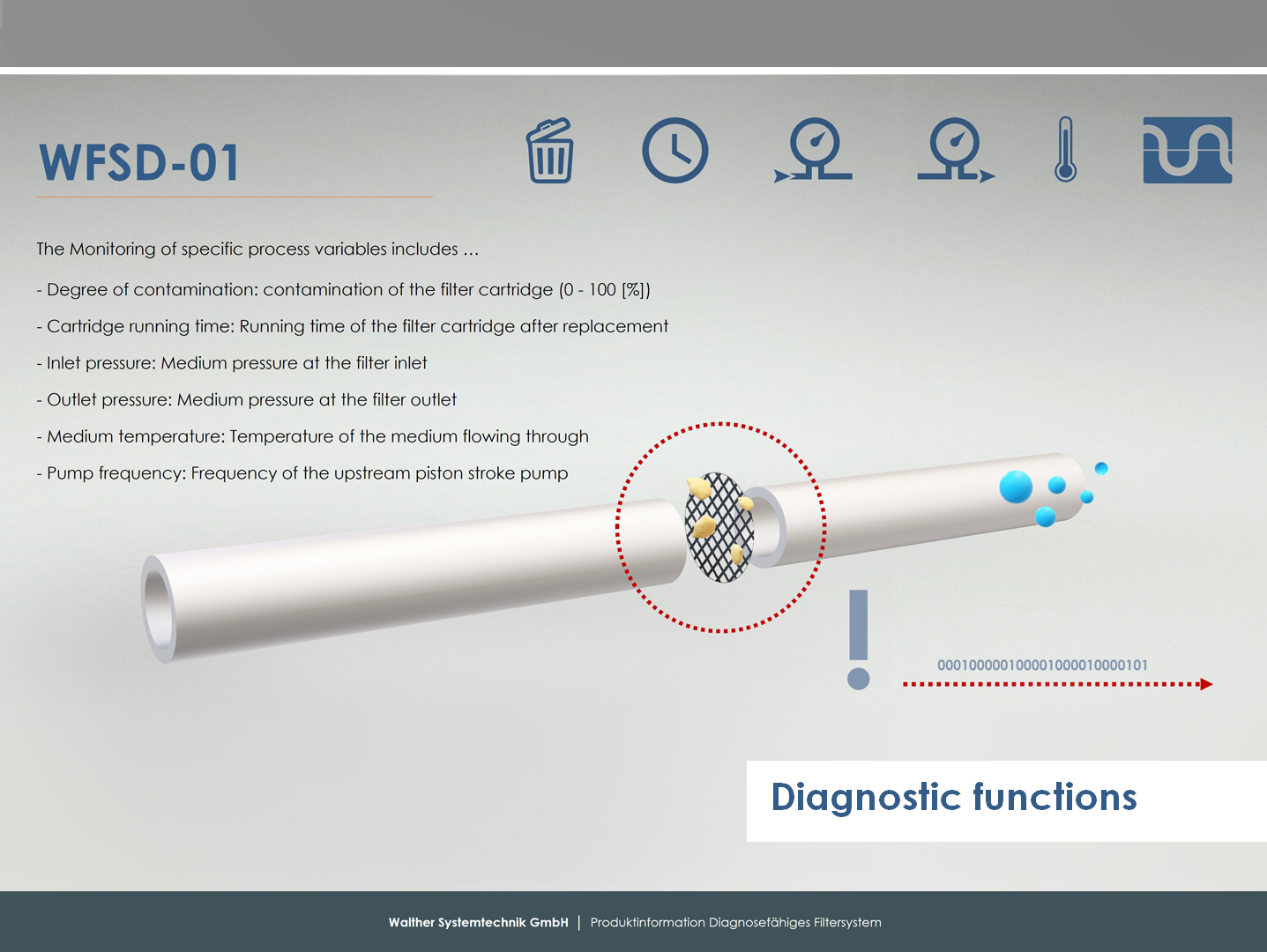

Just in time for Motek, the company is presenting the WFSD-01, a diagnostic-capable filter system for lubricants, and the WADS-01, a stand-alone solution for detecting and ejecting gas inclusions in liquid and viscous materials, two production-supporting add-ons that record process-related parameters by means of real-time monitoring.

Recorded data includes planned and unplanned downtime, error messages and numerous target/actual comparisons. The permanent logging of parameters enables a cycle-accurate response. Since it is also possible to report when definable thresholds are exceeded or not reached, direct action can also be taken. Intelligent diagnostics therefore significantly speed up fault analysis and provide an essential basis for calculating OEE.

In summary, the common denominator of the two product innovations is their intelligent control functions, which ensure maximum accuracy and efficiency: both solutions sustainably stabilise the production process, avoid waste and save costs.

In addition, they are vendor-independent and can be easily integrated into any system, offering complete flexibility to both existing and new customers. In addition to the WFSD-01, which is part of the new Walther Modular product line, six other very compact innovations will be presented. This year, the company is focusing on the efficiency and process reliability of dispensing and application applications in terms of system effectiveness.

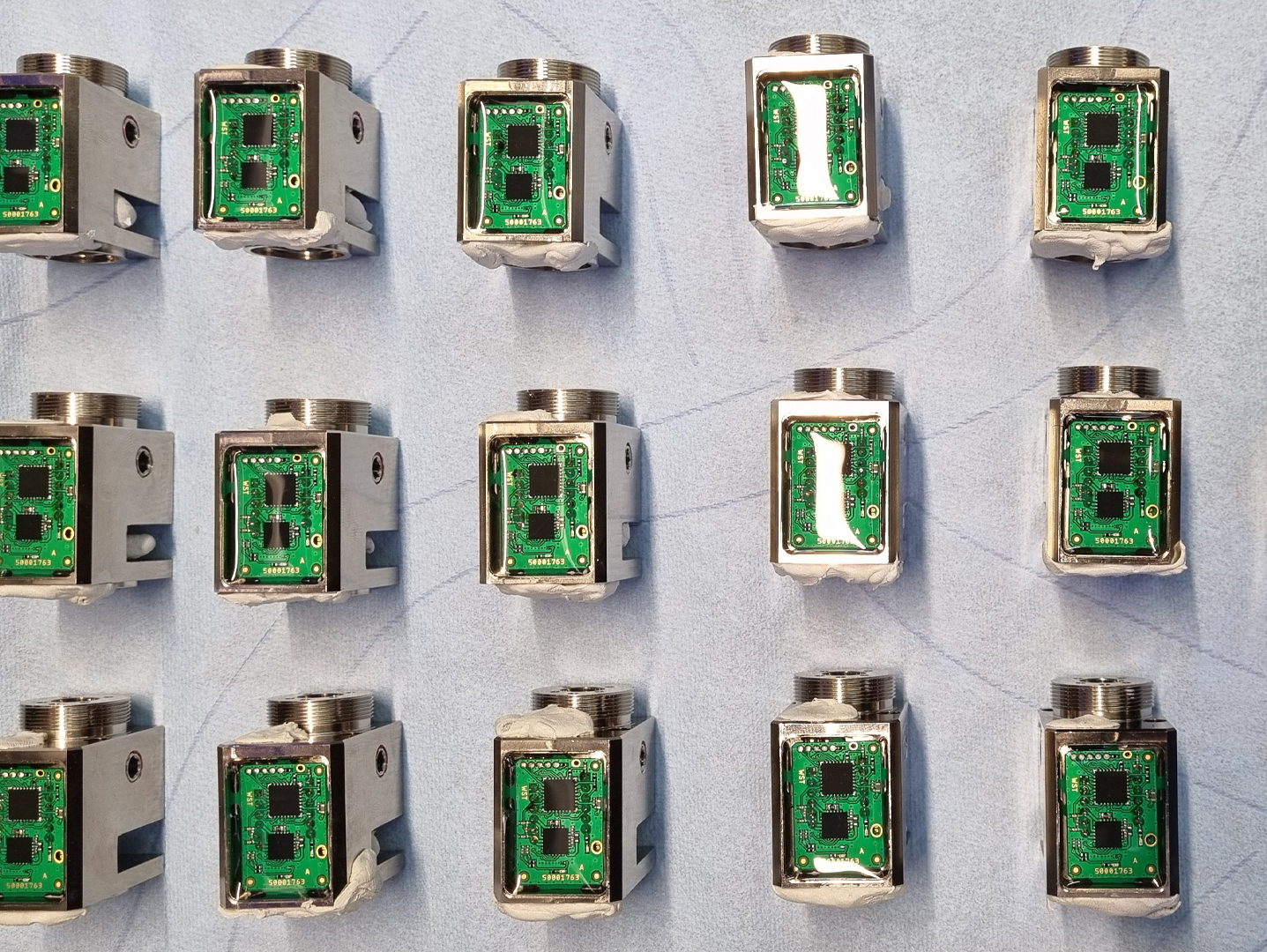

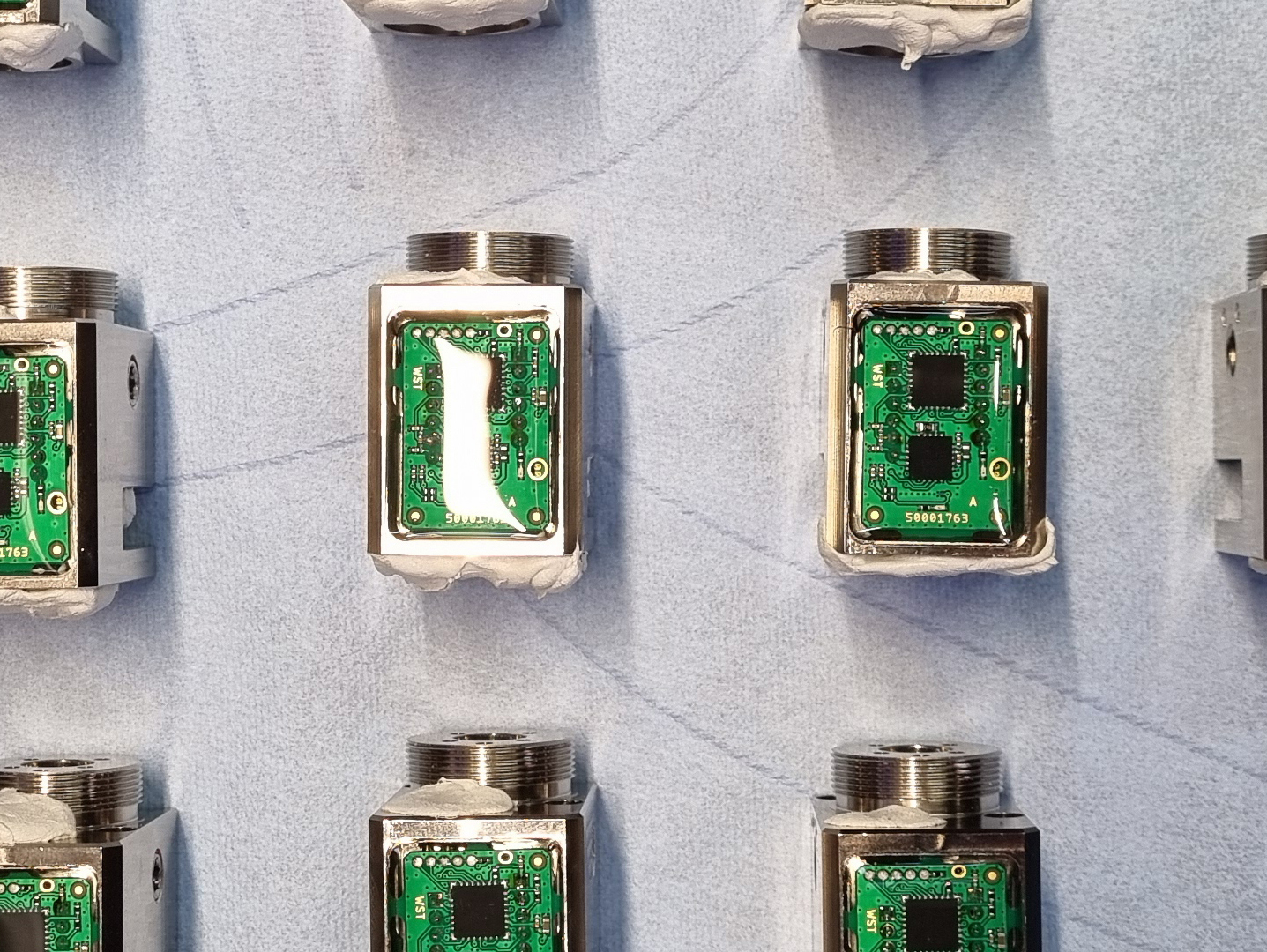

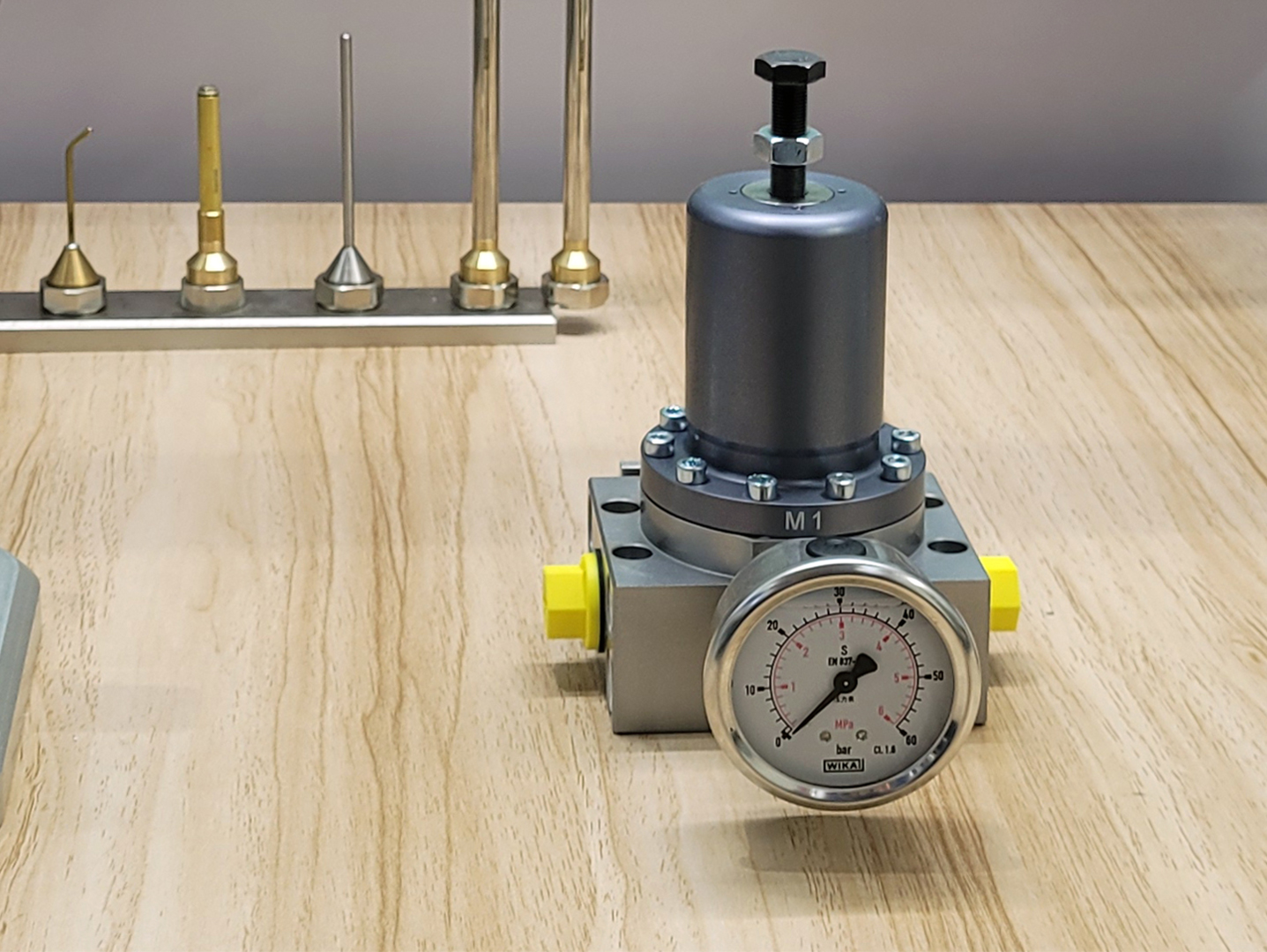

Of course, visitors will also have the opportunity to familiarise themselves with the extensive product range on all days of the exhibition. In addition to customised solutions, Walther Systemtechnik GmbH offers a wide range of standard products. Drum lift pumps, dosing and outlet valves or testing technology such as pressure and optical sensors are just a small selection from the product portfolio.

Contact us; appointments can be made by telephone on 07274-7022-0. You will find the company in Hall 3, Stand 3211.

Smart solutions for automated conveying, dosing and application processes

Germersheim, 10.09.2019: At Motek 2019, Walther Systemtechnik GmbH will be presenting intelligent systems for material preparation with optimum practical benefits.

Whether material preparation systems with intelligent analysis functions, extremely compact modular components or cobot-dominated application processes - at Motek 2019, Walther Systemtechnik GmbH will be presenting innovative new products that measurably increase output and can be easily integrated into existing production chains.

The Germersheim-based company is increasingly relying on intelligent solutions and digitalised products to avoid or identify production obstacles. This is also reflected in the new product portfolio.

Just in time for Motek, the company is presenting the WFSD-01, a diagnostic-capable filter system for lubricants, and the WADS-01, a stand-alone solution for detecting and ejecting gas inclusions in liquid and viscous materials, two production-supporting add-ons that record process-related parameters by means of real-time monitoring.

Recorded data includes planned and unplanned downtime, error messages and numerous target/actual comparisons. The permanent logging of parameters enables a cycle-accurate response. Since it is also possible to report when definable thresholds are exceeded or not reached, direct action can also be taken. Intelligent diagnostics therefore significantly speed up fault analysis and provide an essential basis for calculating OEE.

In summary, the common denominator of the two product innovations is their intelligent control functions, which ensure maximum accuracy and efficiency: both solutions sustainably stabilise the production process, avoid waste and save costs.

In addition, they are vendor-independent and can be easily integrated into any system, offering complete flexibility to both existing and new customers. In addition to the WFSD-01, which is part of the new Walther Modular product line, six other very compact innovations will be presented. This year, the company is focusing on the efficiency and process reliability of dispensing and application applications in terms of system effectiveness.

Of course, visitors will also have the opportunity to familiarise themselves with the extensive product range on all days of the exhibition. In addition to customised solutions, Walther Systemtechnik GmbH offers a wide range of standard products. Drum lift pumps, dosing and outlet valves or testing technology such as pressure and optical sensors are just a small selection from the product portfolio.

Contact us; appointments can be made by telephone on 07274-7022-0. You will find the company in Hall 3, Stand 3211.

further articles

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request