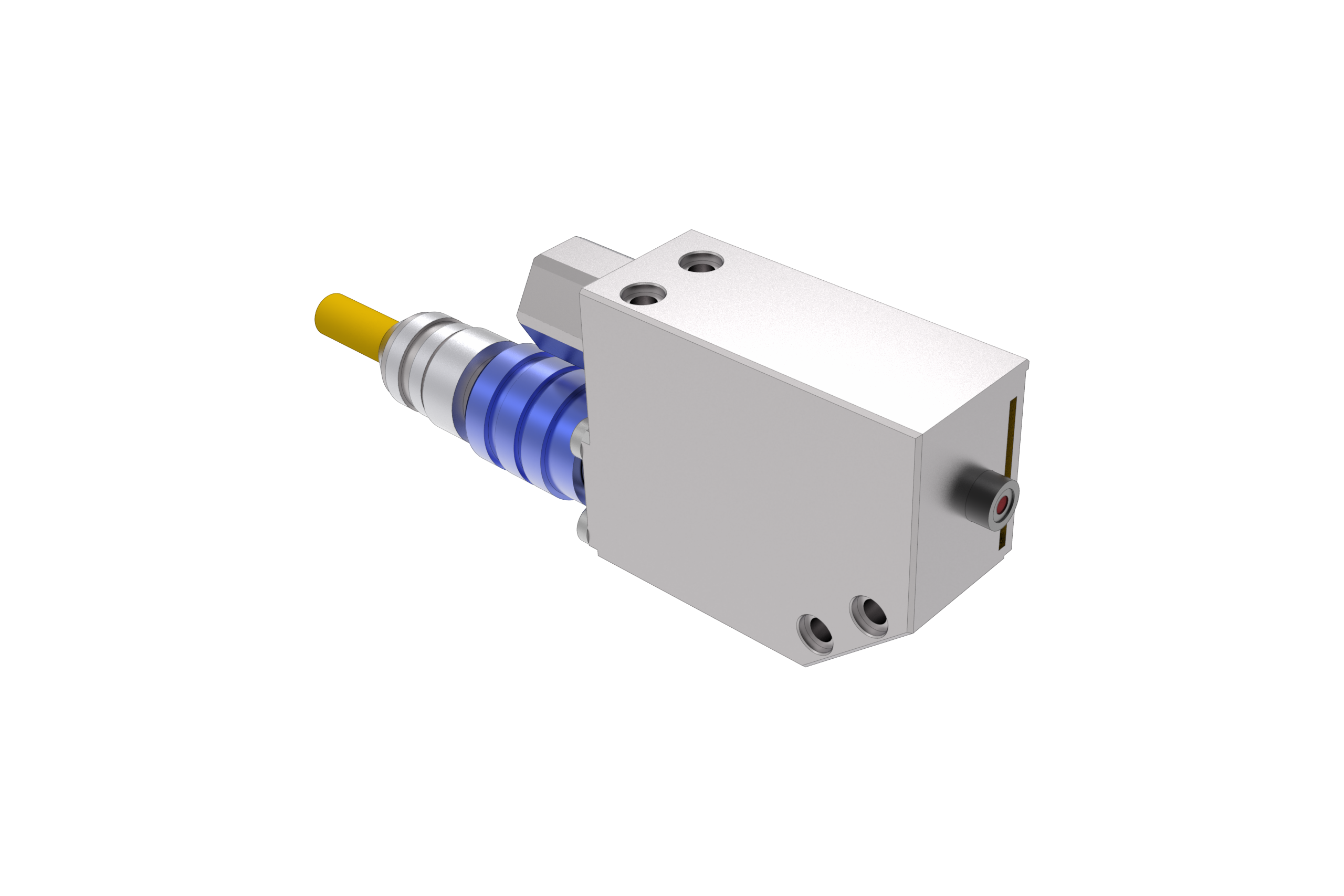

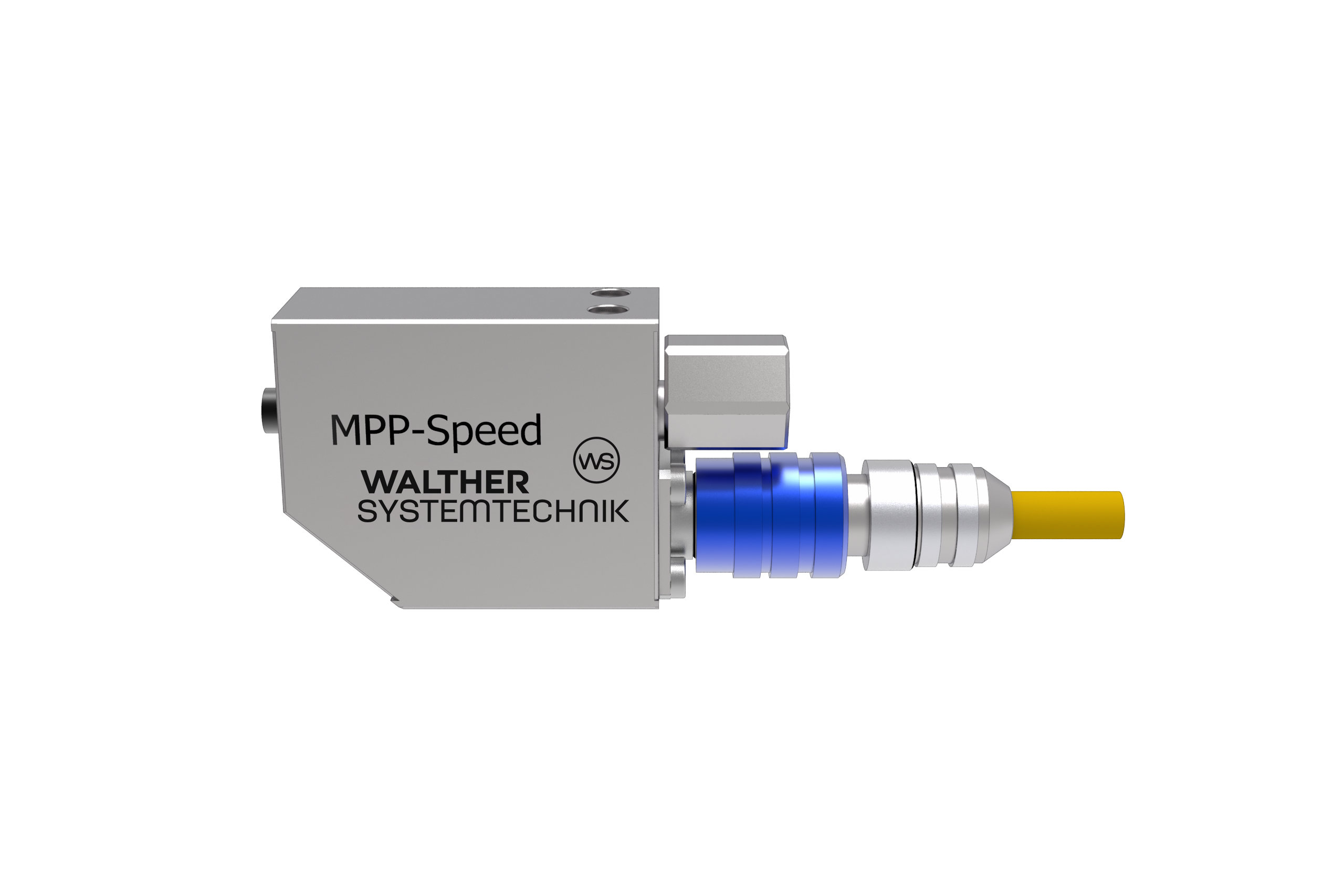

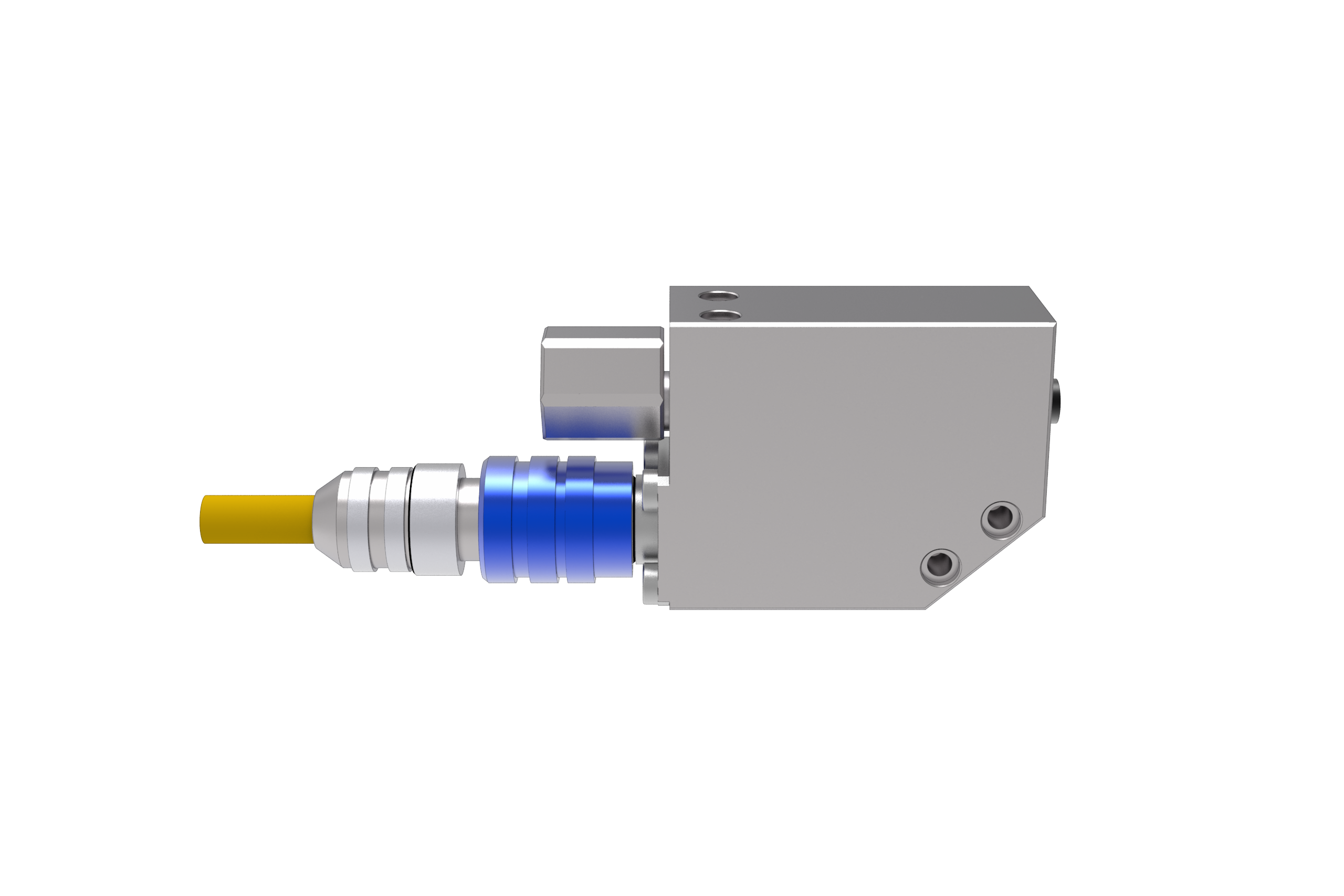

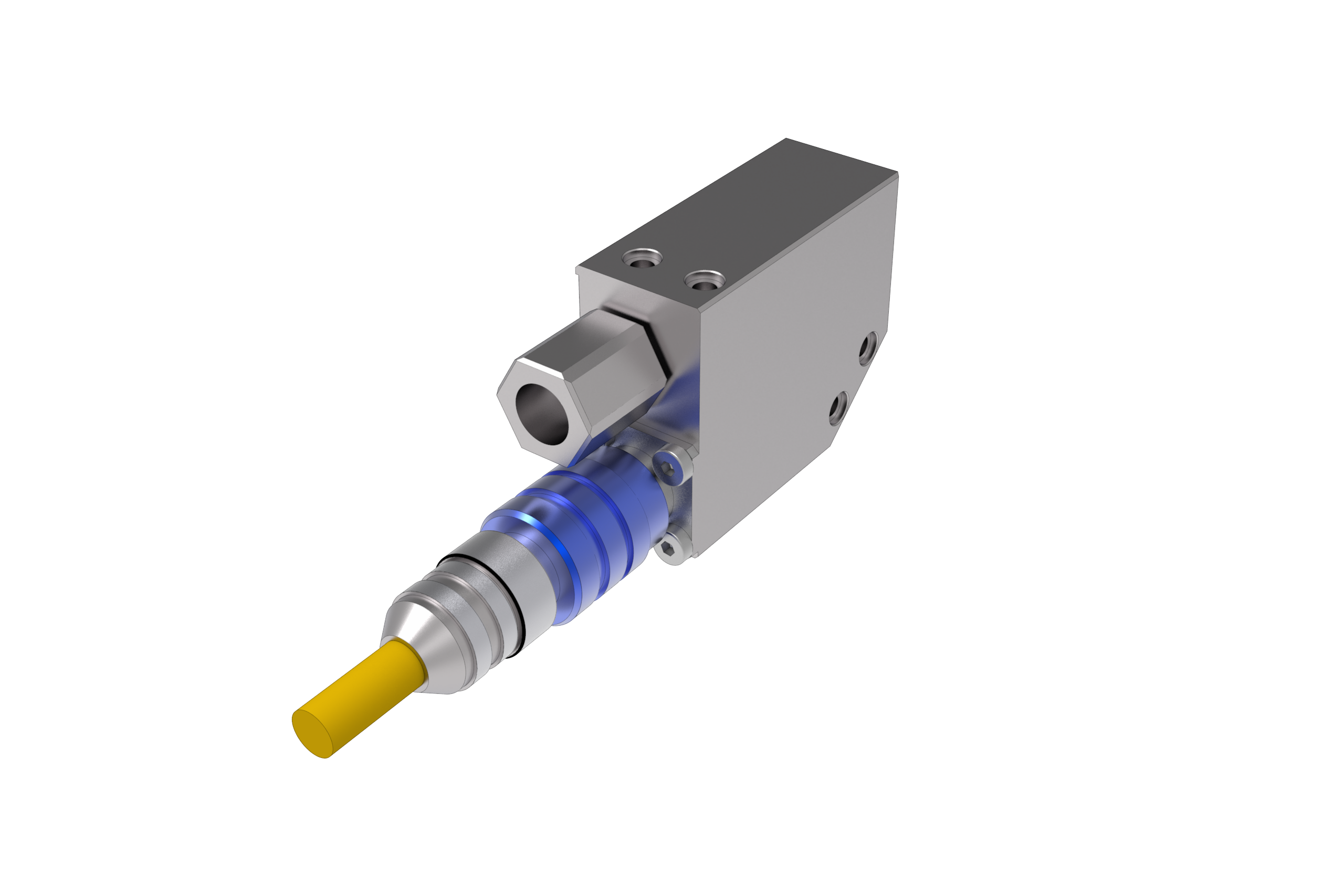

Micro-Point-Pulse Valve MPP-SPEED

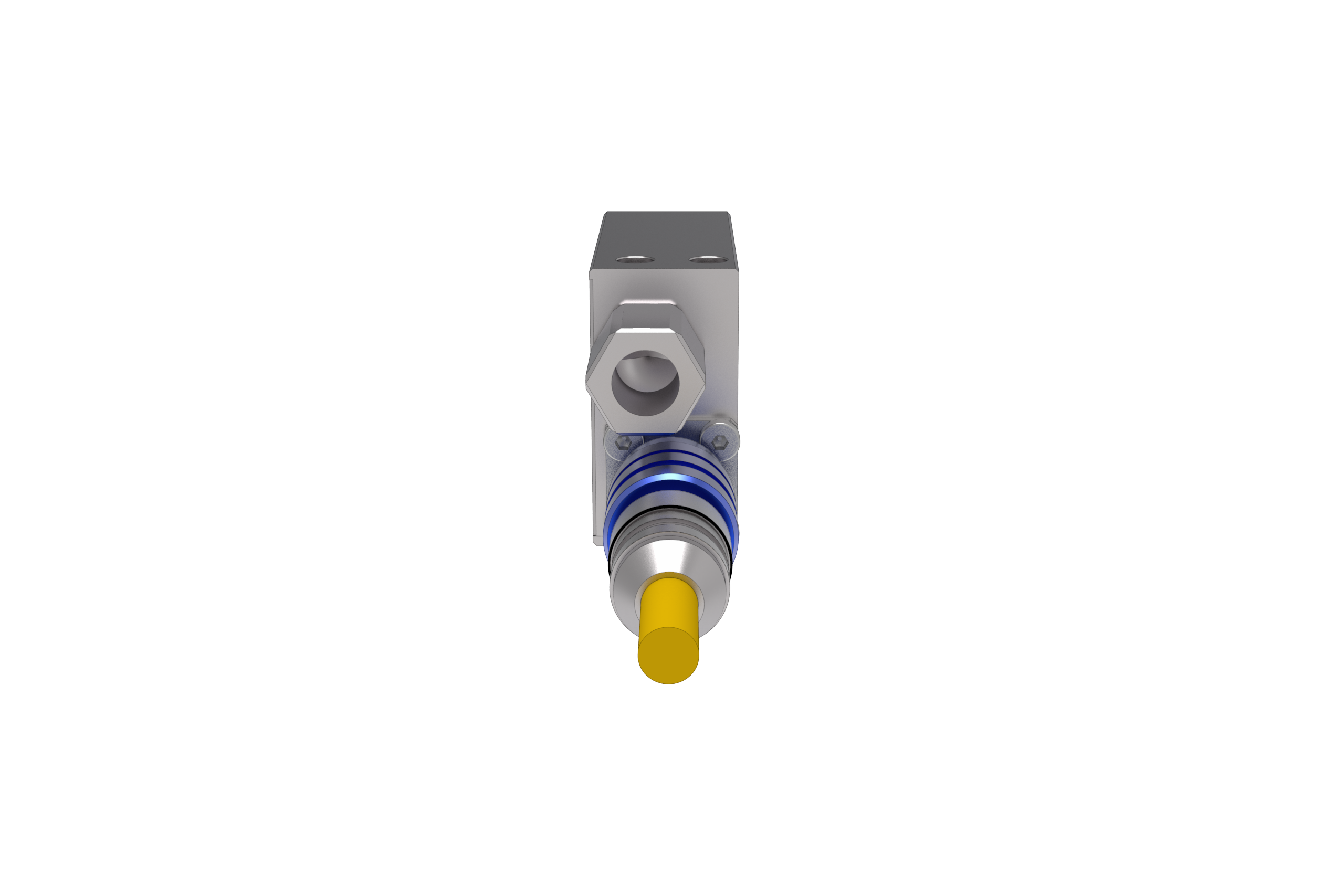

With the Pulse Valves of the MPP-Speed series, you are able to apply different viscous media such as greases, oils, lacquers etc., contact-free and extremely fast. Small drops are shot with high repeat accuracy, covering a distance of up to 35 mm to the component; this allows highly automated, fast and stable production processes, even for very demanding applications.

The application can be done as dots or as beads with extremely high pulsing frequencies of up to 400 Hz. MPP-SPEED Pulse Valves are well suited for applying tiniest dosing quantities (ca. 0,5 µL) and are mostly employed for difficult applications such contact greasing for electric switches and electronic pins, or the oiling of feed phases in pressed connections, or the contact-free lacquering on very small edges for reducing the scattered light of car headlights.

The MPP-Speed Pulse Valve has a high durability of up to 500 million cycles and is therefore perfectly suited for a continuous use in series production. Due to its low weight and a compact design, it is an ideal component for integration into fully automated system.

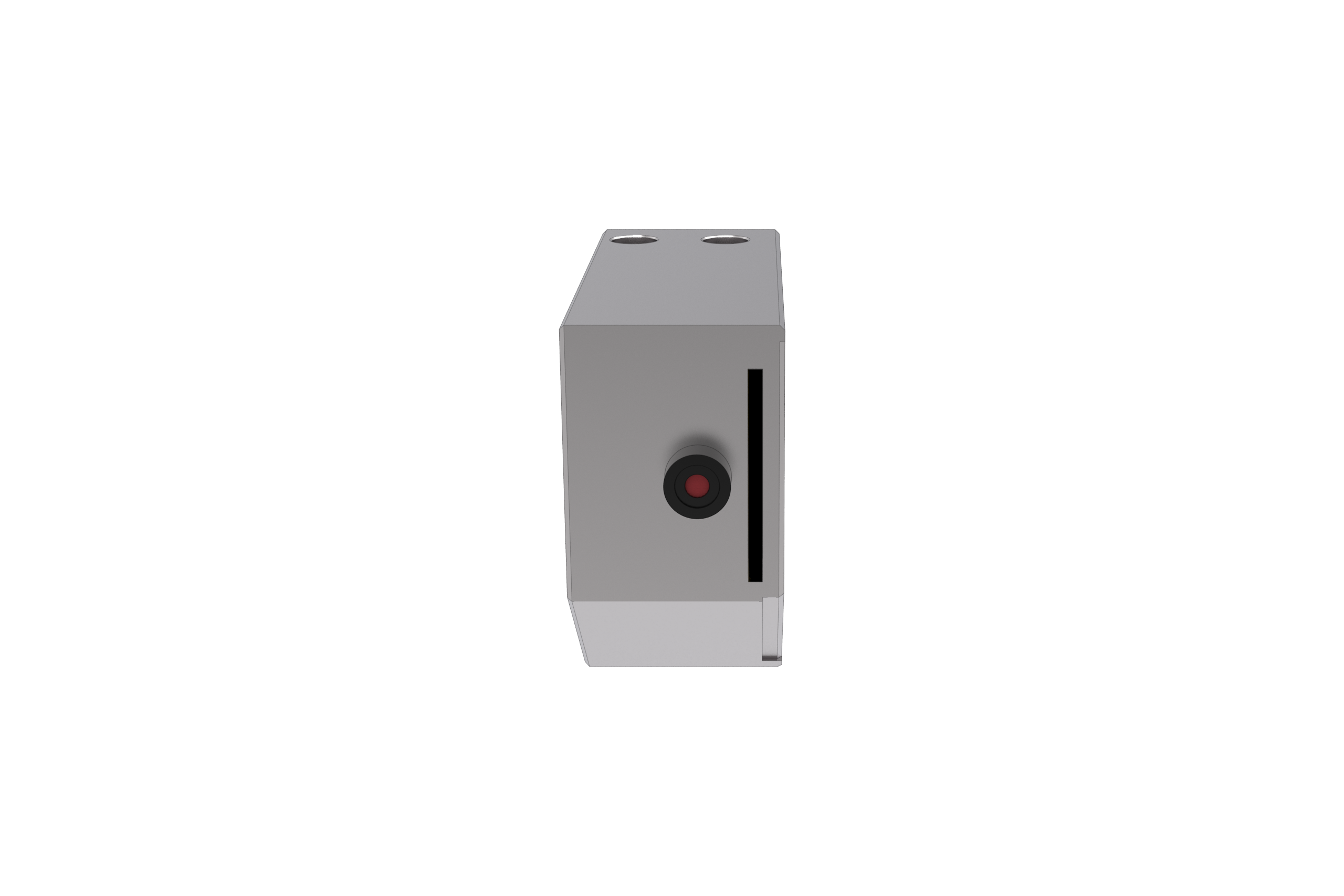

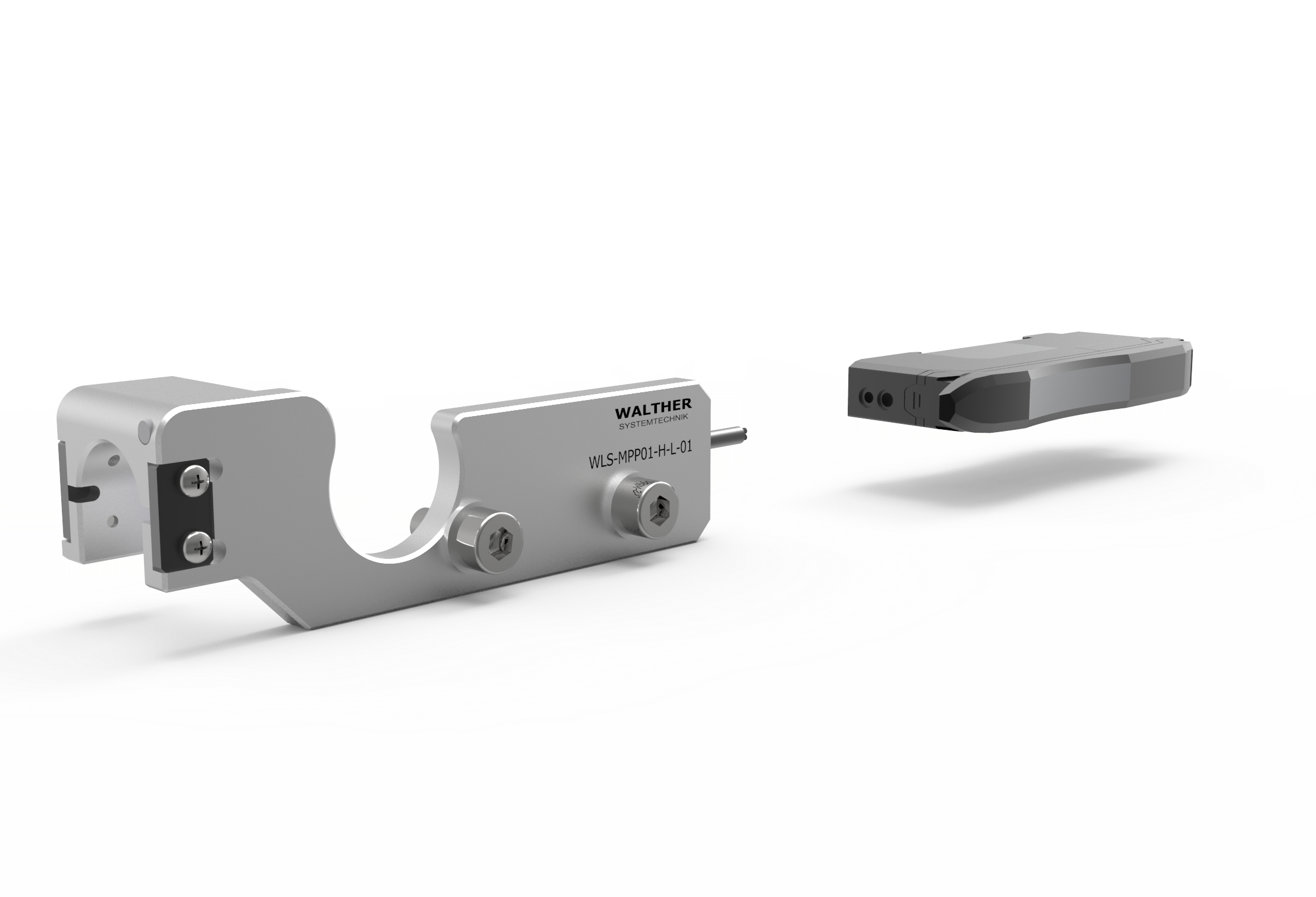

Highest process safety is provided by an optional Light Barrier for monitoring each and every medium dot.

- precise application of minimal quantities possible

- high repeatability

- long lifespan with up to 500 million cycles

- high flexibility due to interchangeable nozzles

- inlet pressure (medium): max. 50 [bar]; nozzle-dependent

- typical dosing quantities: 0.0002 to 0.003 [ml]

- frequency: max. 400 [Hz]

- dimensions (L x W x H): 39 x 62.5 x 20 [mm]

- weight: 120 [g]

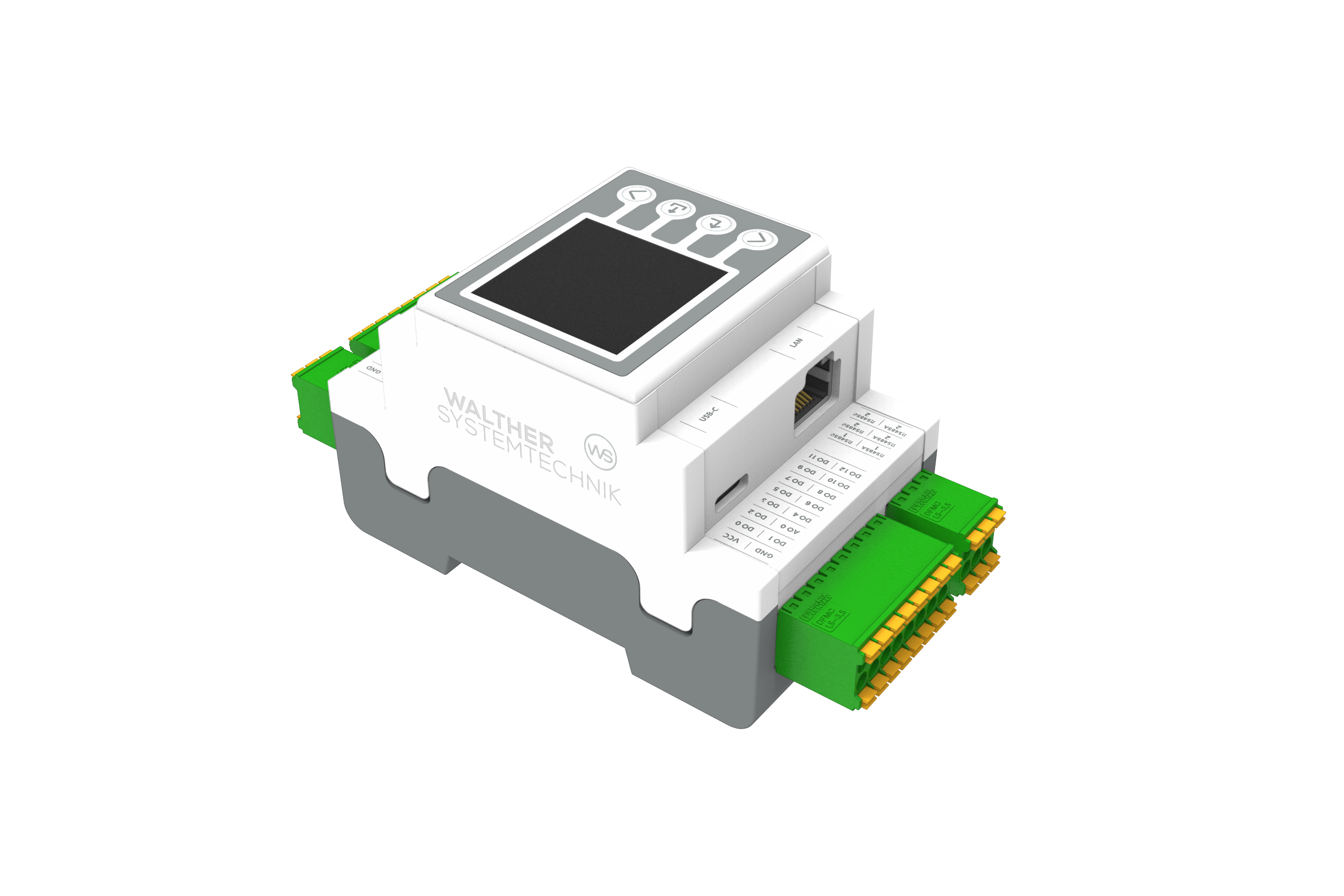

- supply voltage: 24 [V]

- integrated heatin