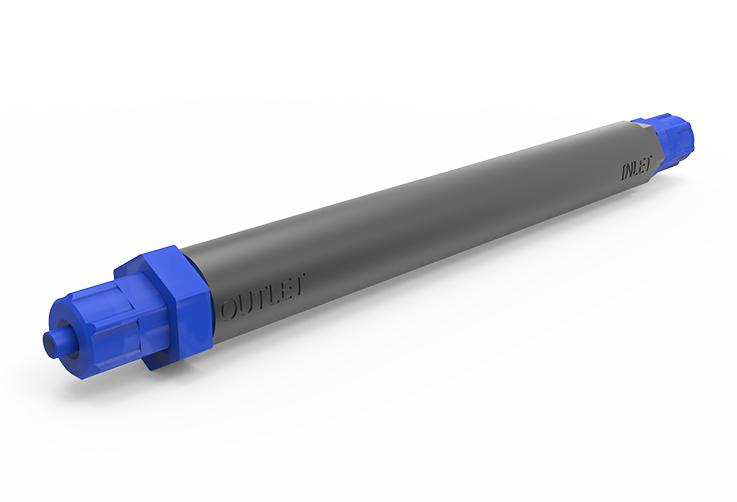

Inline Filter WIF

The inline filter is used to separate particles from liquids and is a practical solution for improving the quality of the medium in fluid systems. It reliably filters out impurities from the medium that could otherwise damage process components. The medium flows through the cartridge, which contains a fine metal mesh. The impurities remain trapped in the mesh and are thus removed from the medium. Once the cartridge is saturated, it must be replaced. The service life of the filter cartridge always depends on the quality of the medium to be filtered.

The inline filters are suitable for all line systems up to max. 10 bar. To install an inline filter retroactively in existing hose lines, the hose is simply cut and the hose ends are connected to the filter inlet and outlet. The choice between different mesh sizes influences how fine the medium is filtered. Due to high-quality materials such as stainless steel and POM, the inline filter is also suitable for corrosive media.

- simple, quick hose assembly

- filter housing made of high-quality stainless steel and also suitable for corrosive media

- for line systems up to max. 10 bar

- filter fineness / mesh density selectable

- operating pressure: max 10 [bar]

- weight: 0,2 [kg]

- material of main body: stainless steel

- dimensions: Ø 20 x 160 [mm]