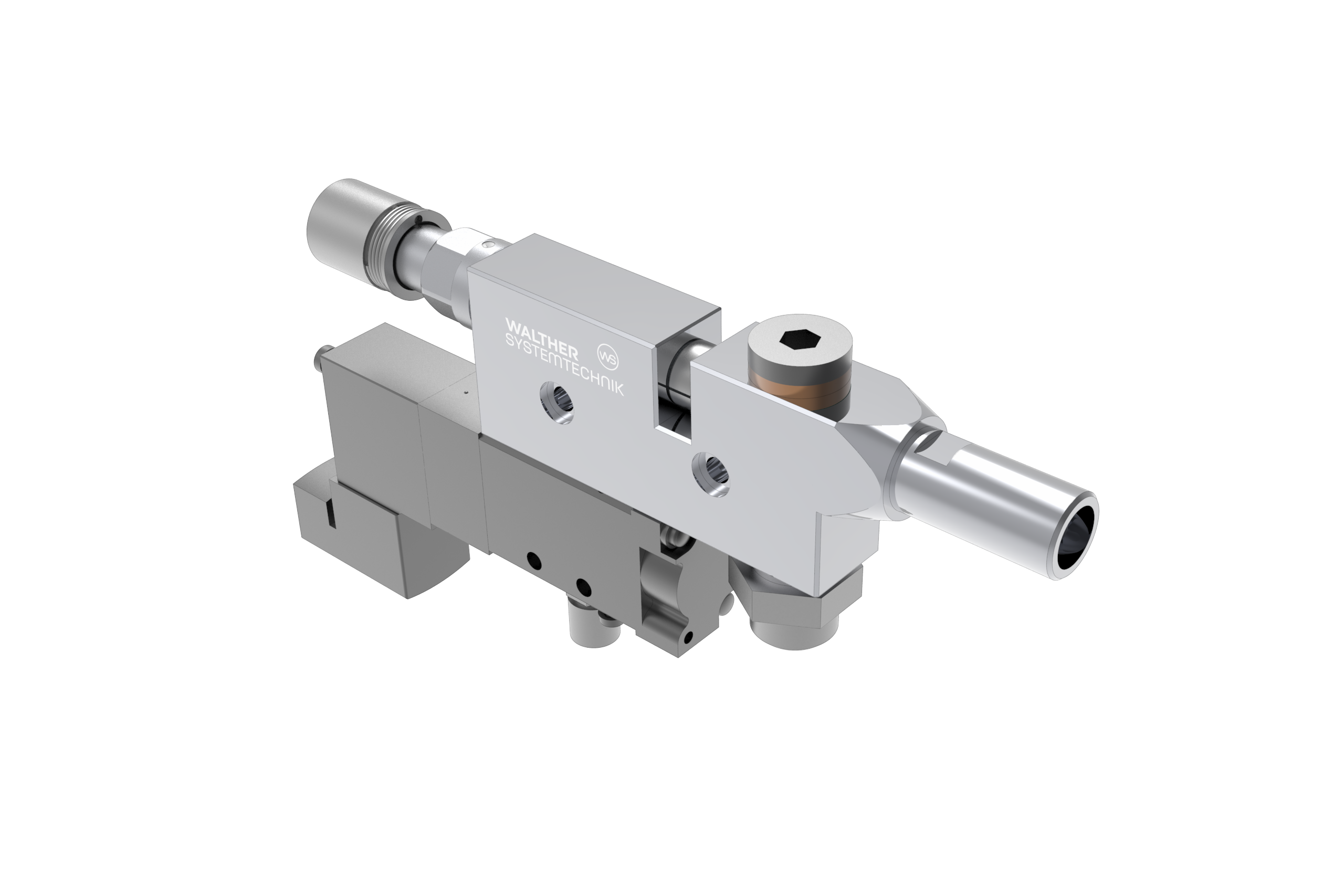

Full-jet Valve VMS-02

With a Full-Jet Valve of the VMS-02 series, you will refer to a robust and very fast switching, pneumatically controlled application valve which is suitable for the continuous or intermitting application of different media and a broad range of viscosity, in particular for sealing compounds, glues and oils.

User appreciate the high precision and excellent repeatability of the applied quantity; they also select the VMS-02 full-jet valves due to their low weight and compact design. They are ideal for high traversing speeds and integration in machines or robots with only little space for installation.

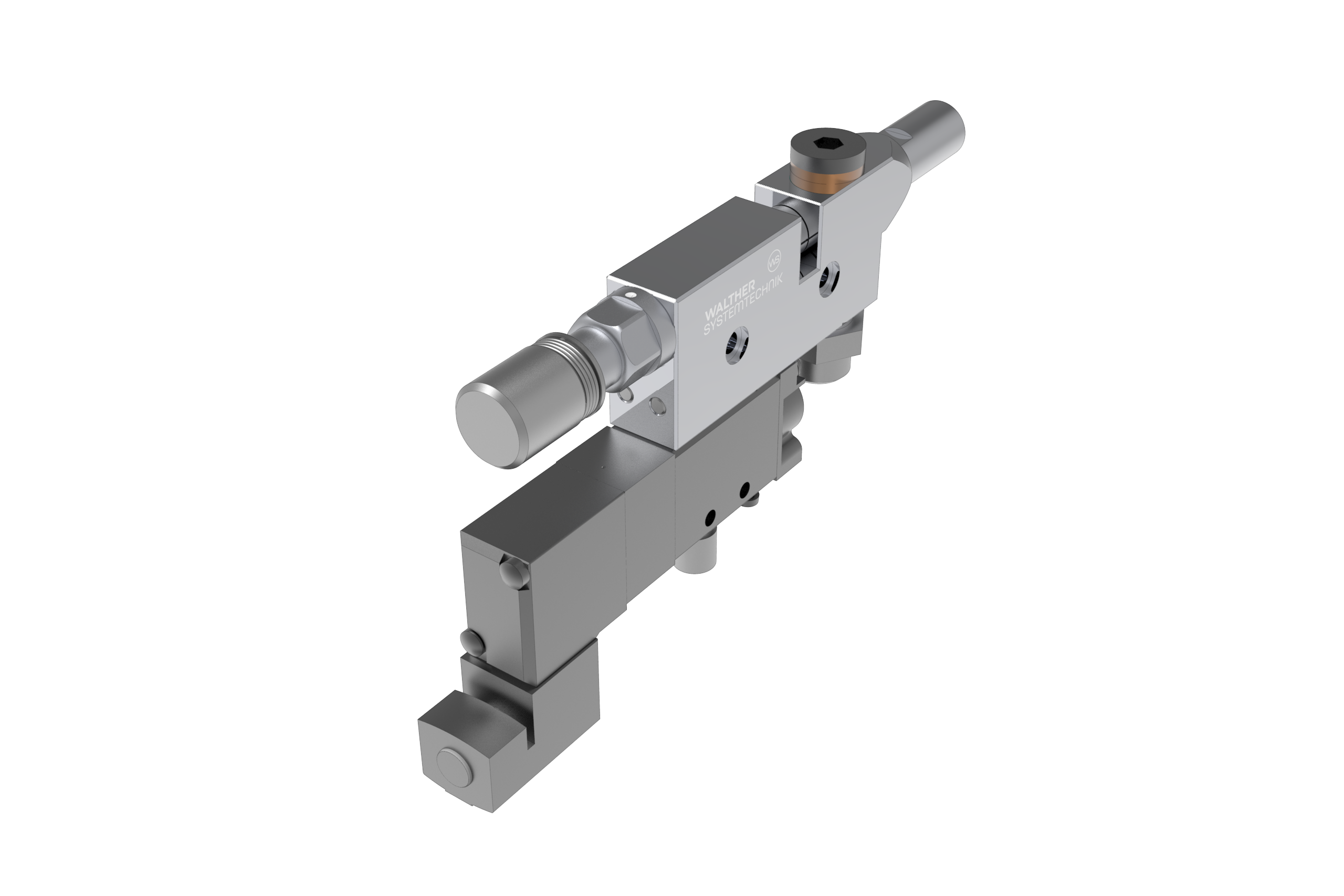

Valves of the VMS-02 series were designed for material pressures up to 100 bar and with the directly flanged 5/2-way valve, they can reach up to 20 tacts per second under the respective operating conditions. The discharge of the material is carried out as a full jet. Heating plates, a sensor for the valve status, different nozzles and needles as well as multiple adapted nozzle extensions are available for this versatile application valve and offer additional flexibility.

- broad spectrum of use for different media and wide range of viscosity

- high flexibility due to replaceable nozzle and dosing needle

- optional heating plate available for valve tempering

- control air pressure: 6 [bar]

- material pressure: max. 100 [bar]

- weight: 375 [g]

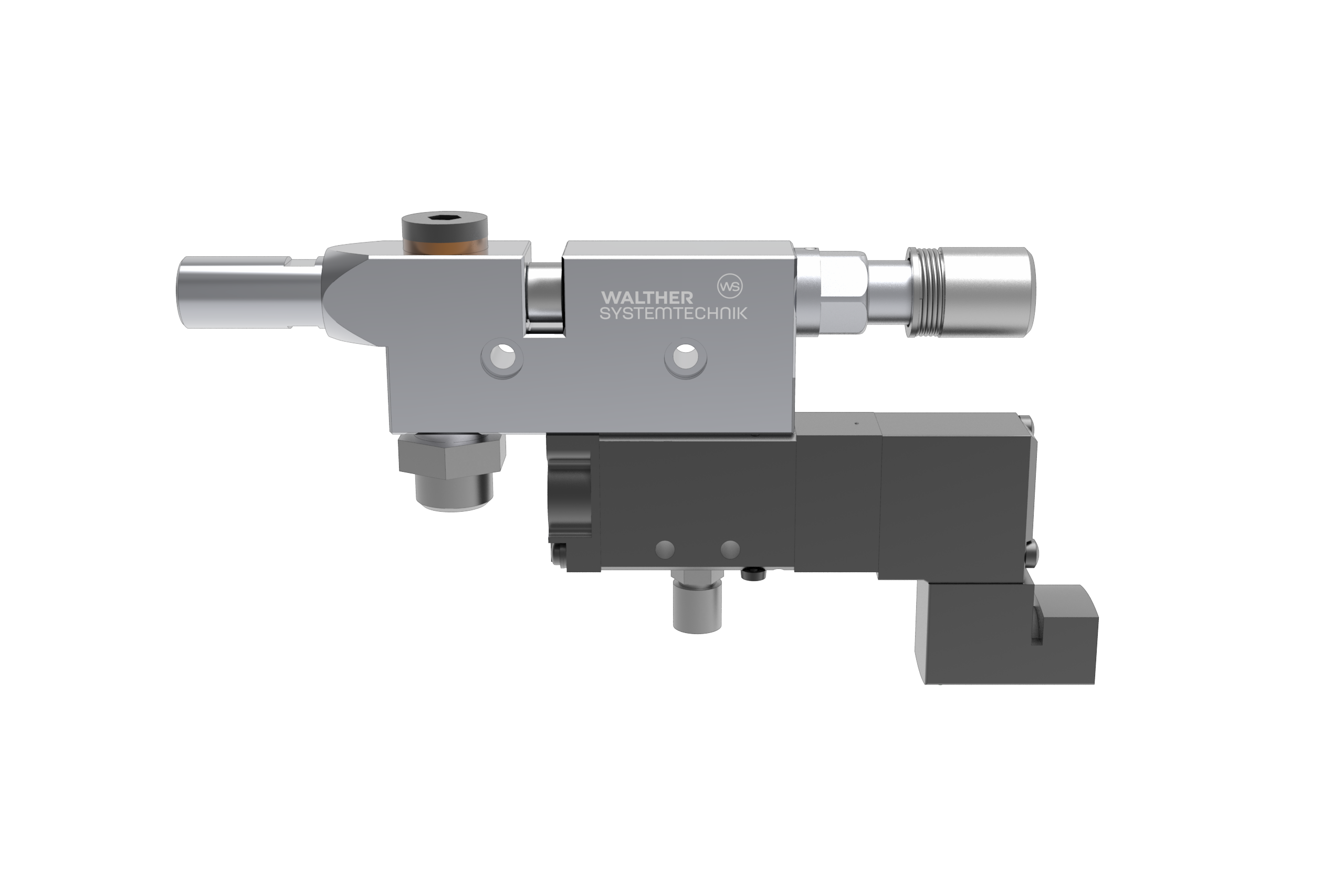

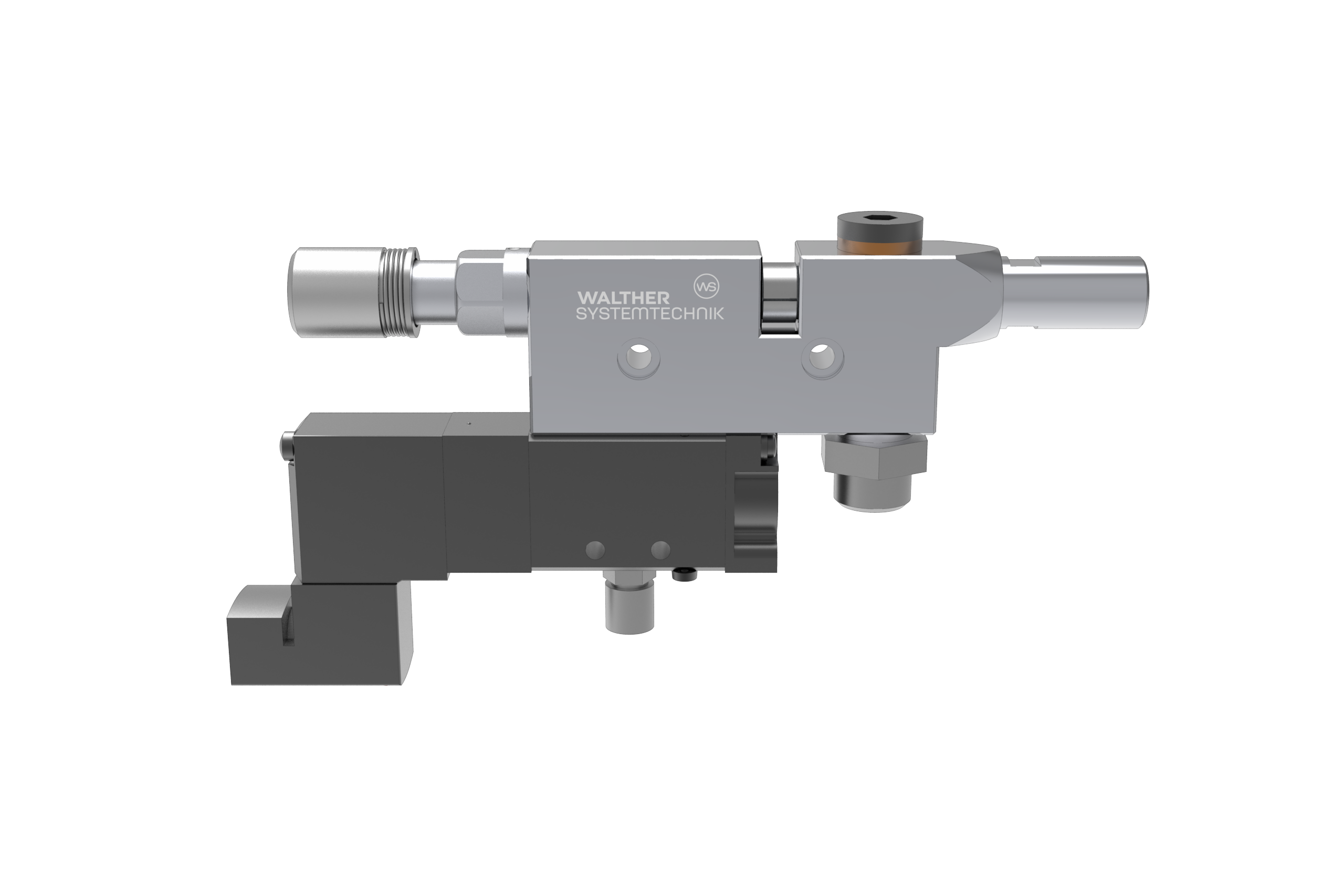

- dimensions KV-version (l x w x h): 144x15x82 [mm]

- dimensions LV-version (l x w x h): 162x15x82 [mm]

- connection „material“: G1/8

- connection „control air“: screw joint for hose 6/4

- available nozzle diameters: 0,2 / 0,3 / 0,5 / 0,8 / 1,0 / 1,2 / 1,5 / 2,0 / 2,5 [mm]

- material - nozzle: stainless steel - needle: carbide

- sealings: Viton