Digitalisation in the field of dosing technology: Walther goes digital

23 Sept 2021, 10:00:00

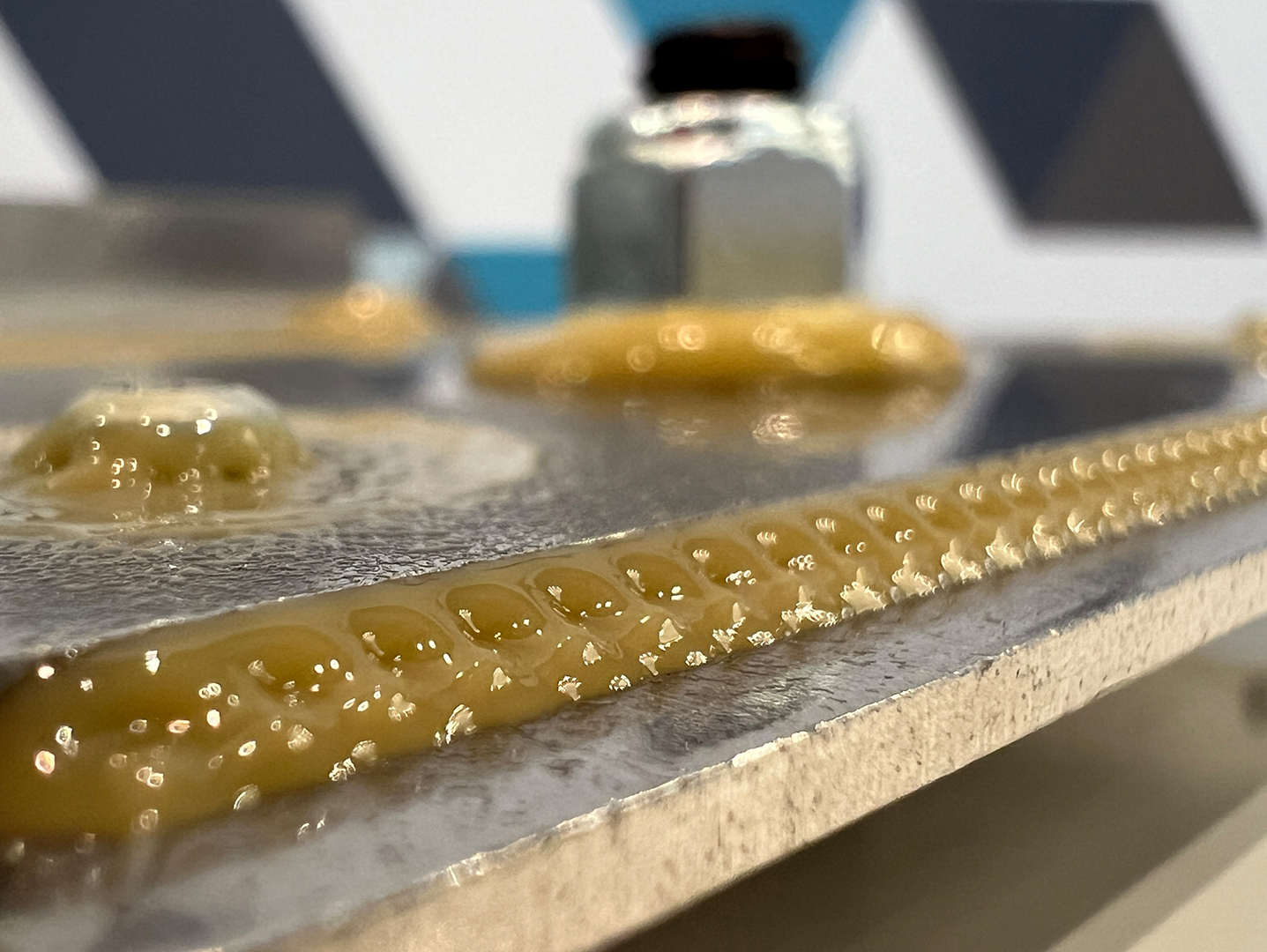

Germersheim, 23 September 2021: The reliable conveying, dosing and application of liquid and pasty media plays a central role in ensuring the function and safety of products in almost all industries. Walther Systemtechnik GmbH has been developing dosing components and systems for over two decades and has established itself as a reliable partner for the realisation of standard solutions through to individual complete systems.

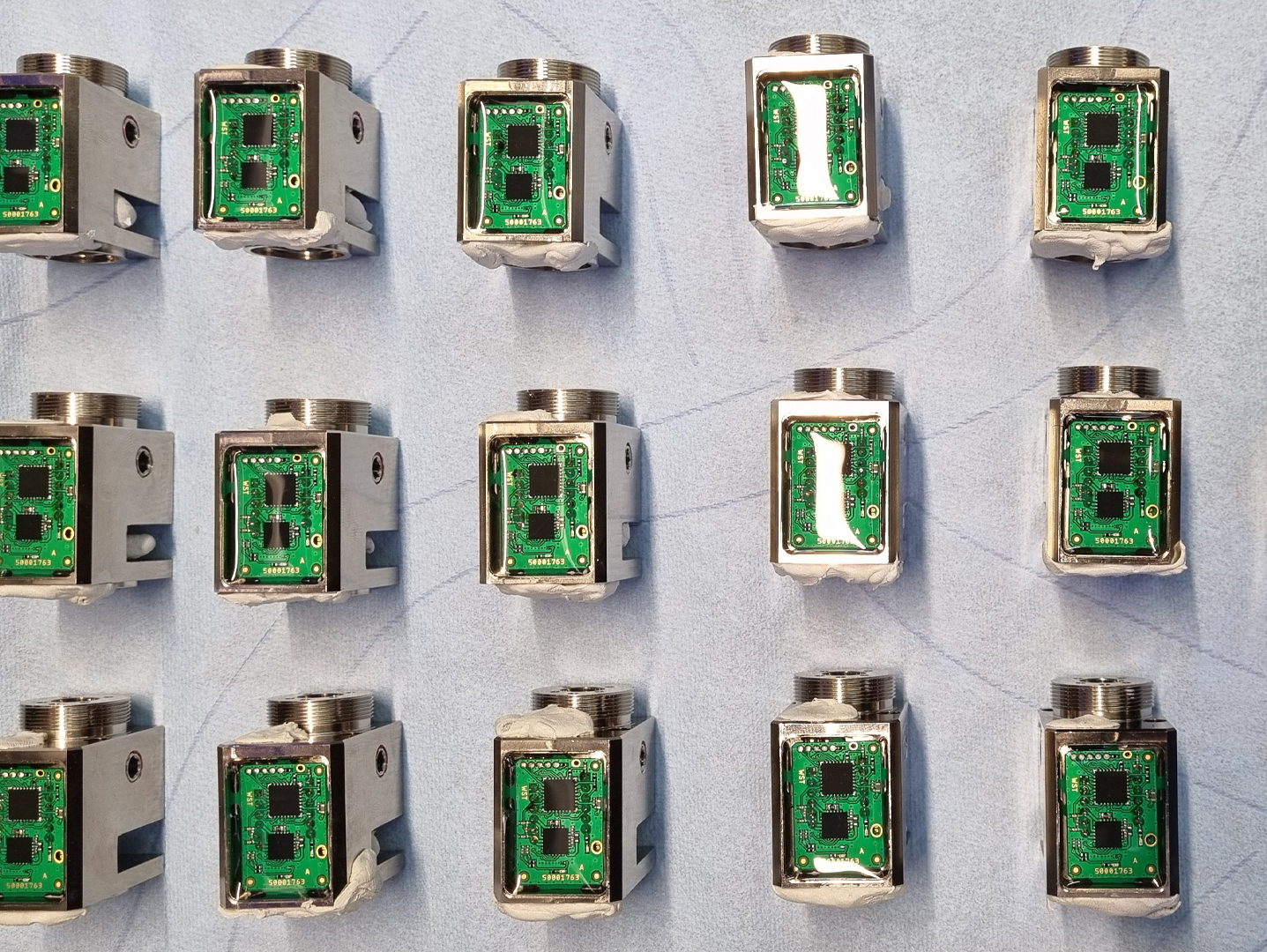

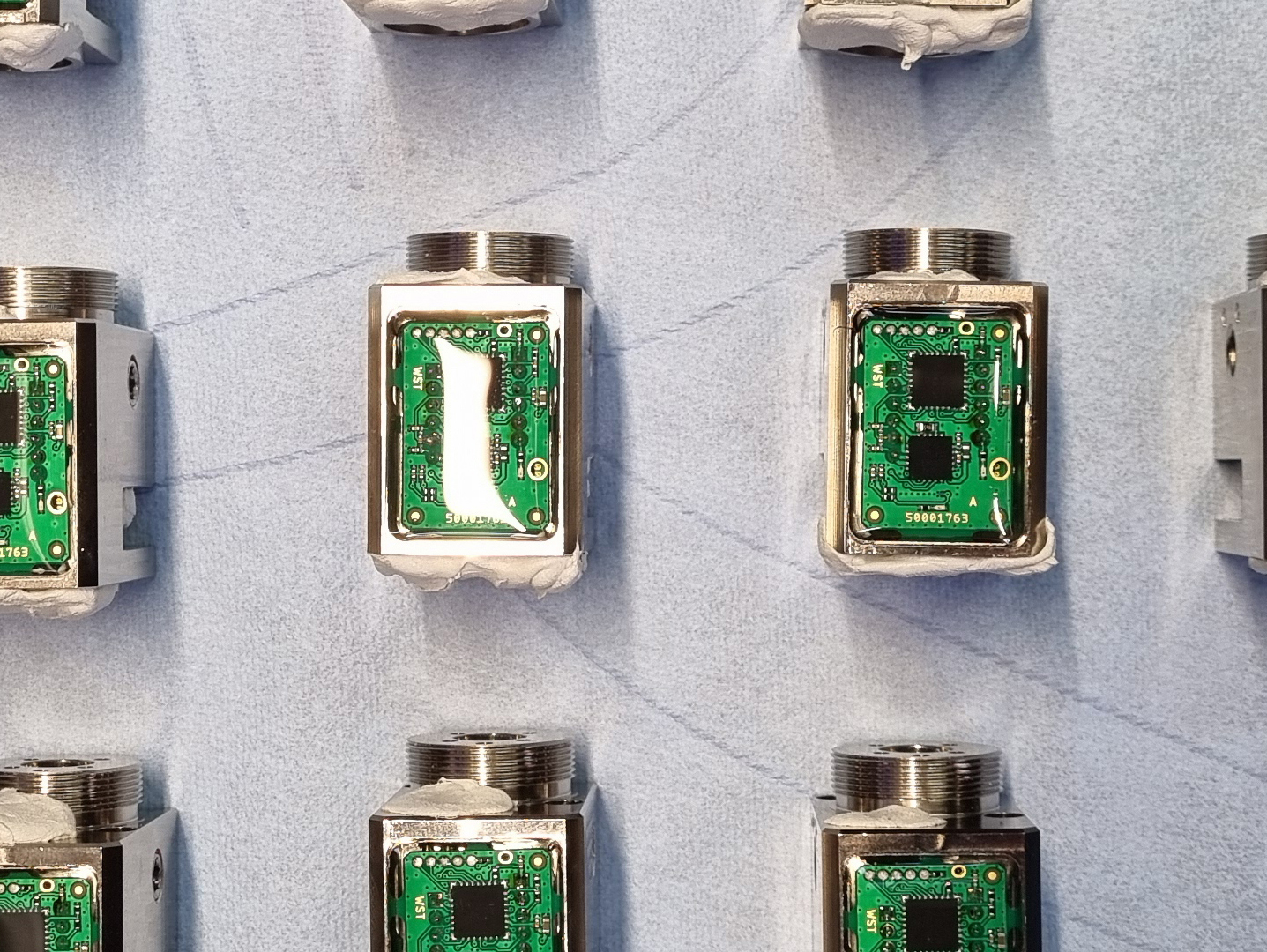

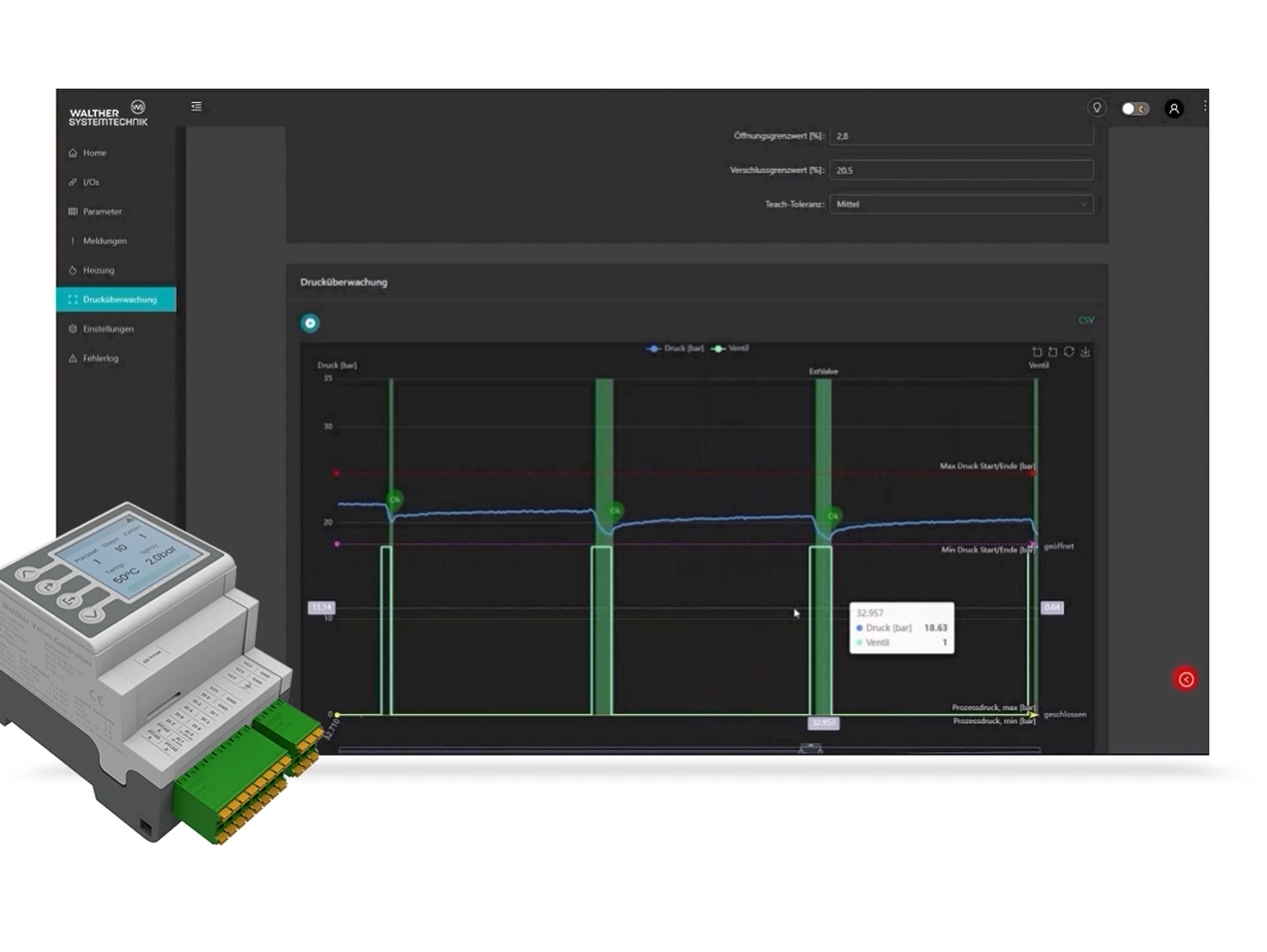

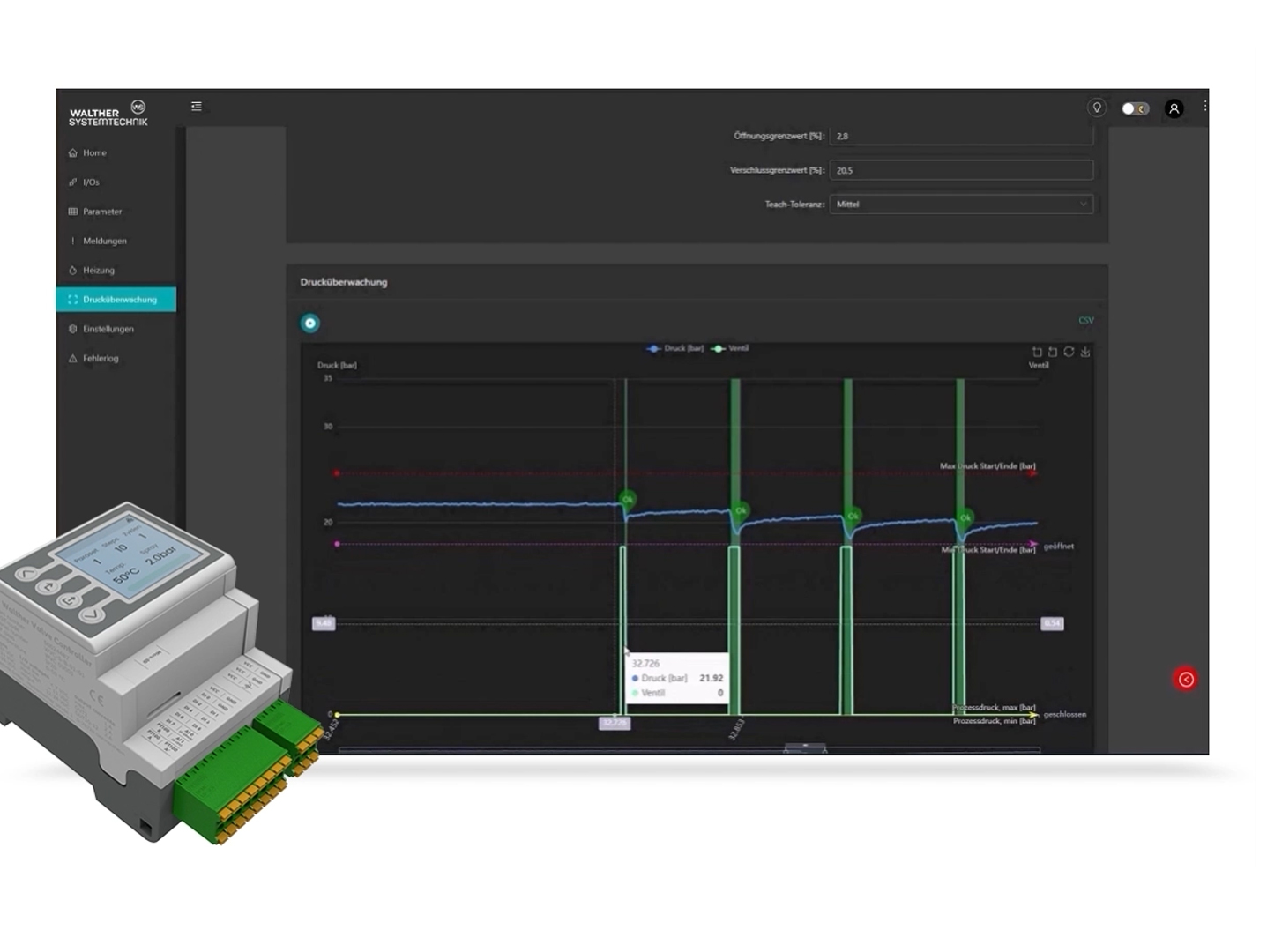

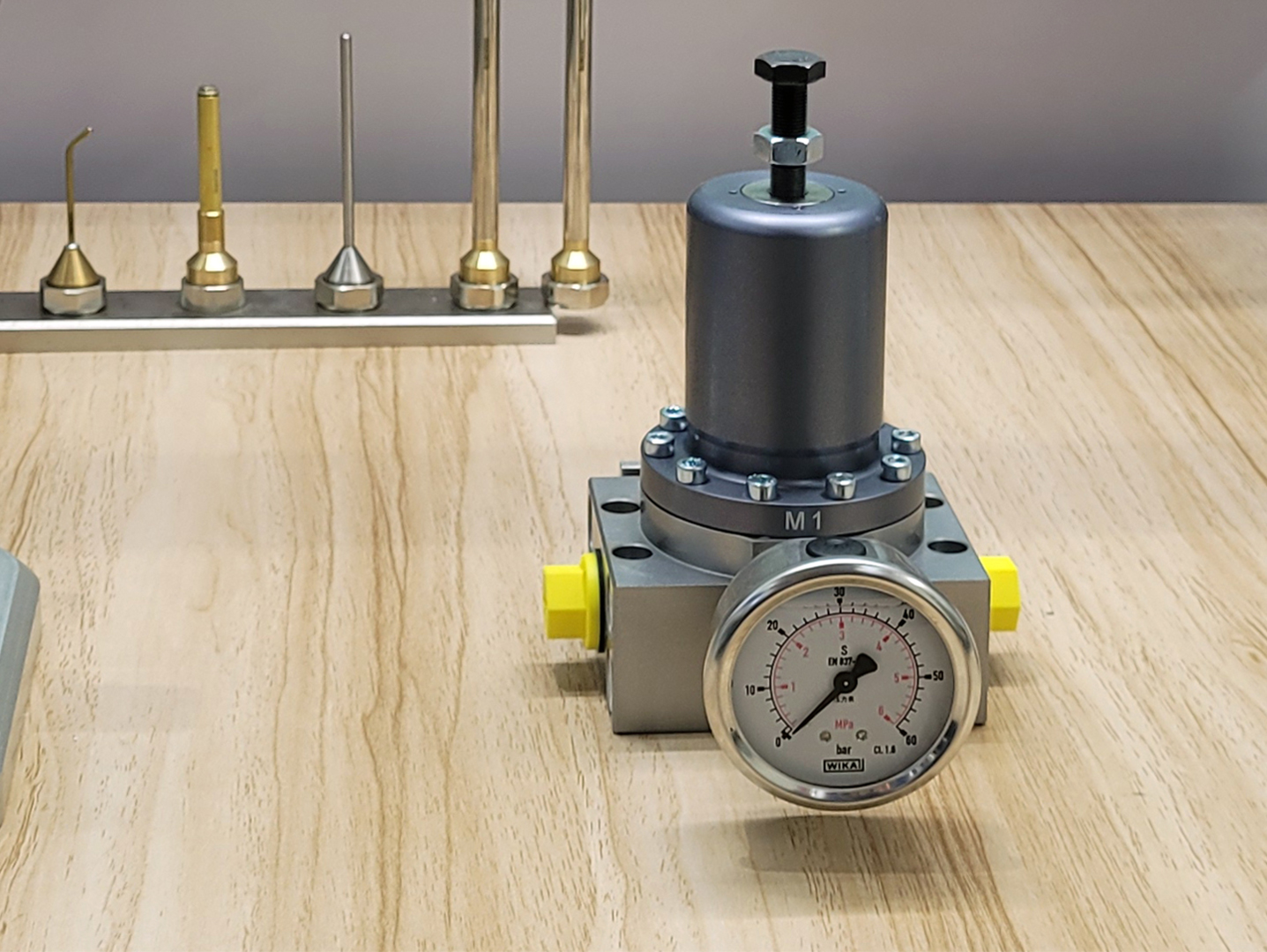

As a driver of innovation, Walther's current I4.0 product family is the latest step in the digitalisation of dosing technology, thus ensuring the future viability of its customers' applications. Whether pumps, media reservoirs, filter systems or modules for air bubble ejection, within the new product family important process and status variables can be recorded in real time using suitable sensors and transferred via analogue and digital interfaces - for example to the system control. This provides the user with new opportunities to increase process capability, Overall Equipment Effectiveness (OEE) and product quality.

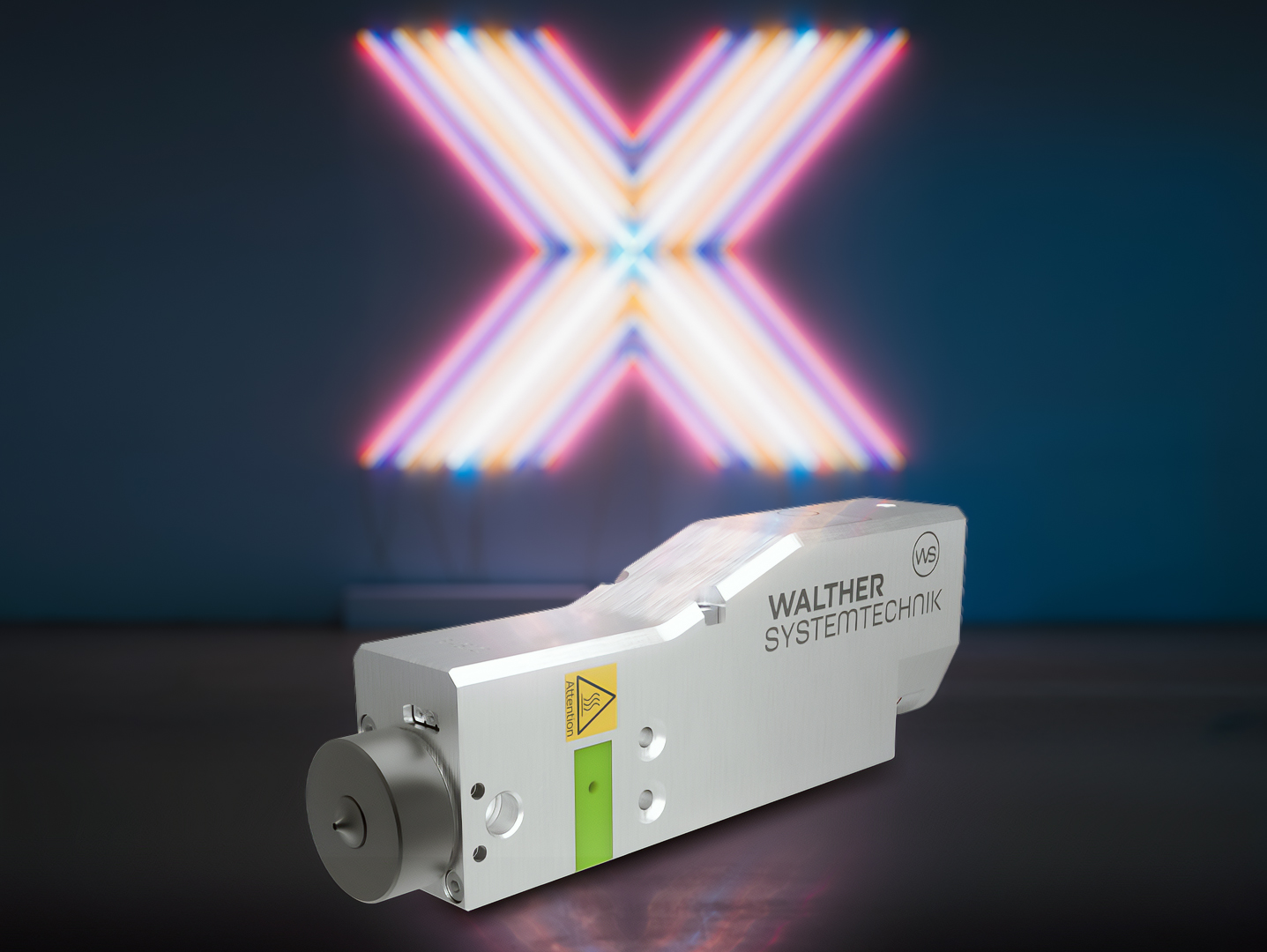

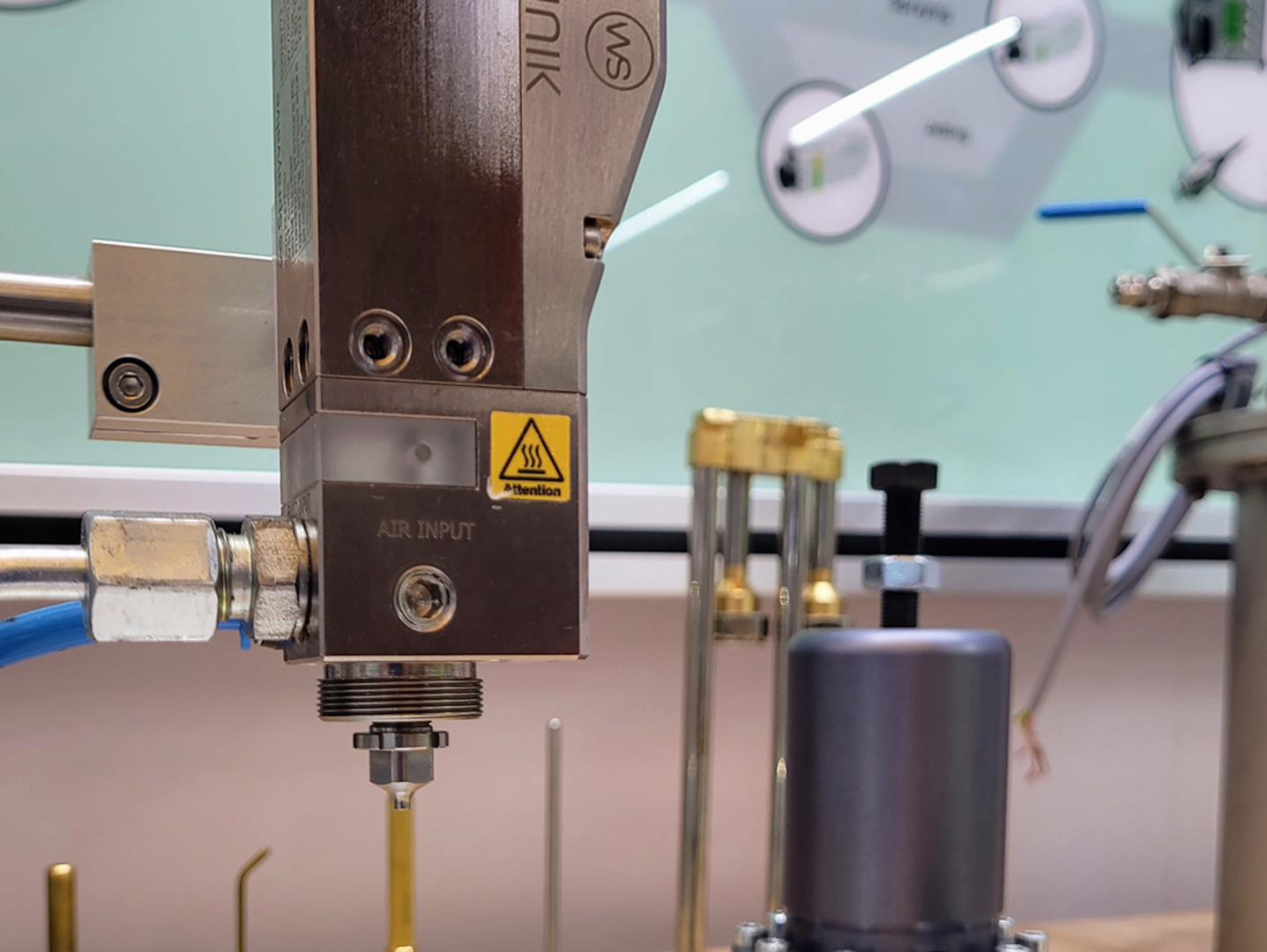

This is illustrated by the latest addition to the I4.0 product family, the WSV spray valve. Designed from the ground up for the application of low to medium viscosity fluids, the valve's integrated design provides a high level of functionality in a small footprint. It combines a pressure sensor, a valve heater with associated temperature control and the electronics for controlling, monitoring and analysing process data. An analogue output, four digital inputs/outputs and an Ethernet connection allow extensive connectivity to peripheral devices as well as remote parameterisation and diagnostics of the valve. In addition, software ADD-ONS and firmware updates can be installed and activated at a later date if required, giving the operator maximum flexibility.

Thanks to its compact design, the smart valve can be easily integrated into both new and existing systems. No external control technology or additional programming is required, significantly reducing the cost and time of commissioning.

The greatest added value can be achieved by combining it with other fluid components from the I4.0 product family. Various process data can be evaluated and the resulting process understanding can be used to maximise the system performance indicator.

Digitalisation in the field of dosing technology: Walther goes digital

Germersheim, 23 September 2021: The reliable conveying, dosing and application of liquid and pasty media plays a central role in ensuring the function and safety of products in almost all industries. Walther Systemtechnik GmbH has been developing dosing components and systems for over two decades and has established itself as a reliable partner for the realisation of standard solutions through to individual complete systems.

As a driver of innovation, Walther's current I4.0 product family is the latest step in the digitalisation of dosing technology, thus ensuring the future viability of its customers' applications. Whether pumps, media reservoirs, filter systems or modules for air bubble ejection, within the new product family important process and status variables can be recorded in real time using suitable sensors and transferred via analogue and digital interfaces - for example to the system control. This provides the user with new opportunities to increase process capability, Overall Equipment Effectiveness (OEE) and product quality.

This is illustrated by the latest addition to the I4.0 product family, the WSV spray valve. Designed from the ground up for the application of low to medium viscosity fluids, the valve's integrated design provides a high level of functionality in a small footprint. It combines a pressure sensor, a valve heater with associated temperature control and the electronics for controlling, monitoring and analysing process data. An analogue output, four digital inputs/outputs and an Ethernet connection allow extensive connectivity to peripheral devices as well as remote parameterisation and diagnostics of the valve. In addition, software ADD-ONS and firmware updates can be installed and activated at a later date if required, giving the operator maximum flexibility.

Thanks to its compact design, the smart valve can be easily integrated into both new and existing systems. No external control technology or additional programming is required, significantly reducing the cost and time of commissioning.

The greatest added value can be achieved by combining it with other fluid components from the I4.0 product family. Various process data can be evaluated and the resulting process understanding can be used to maximise the system performance indicator.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request