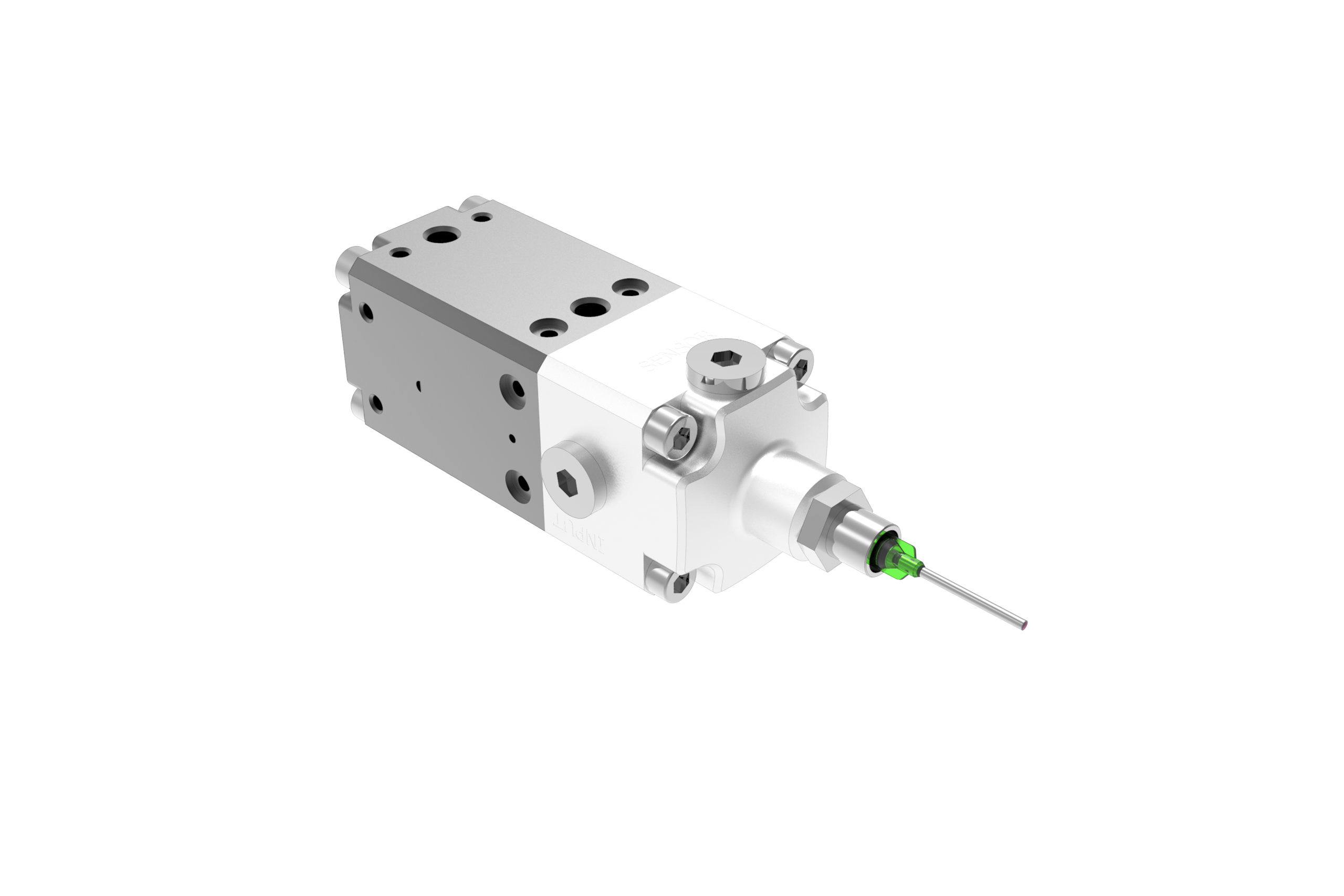

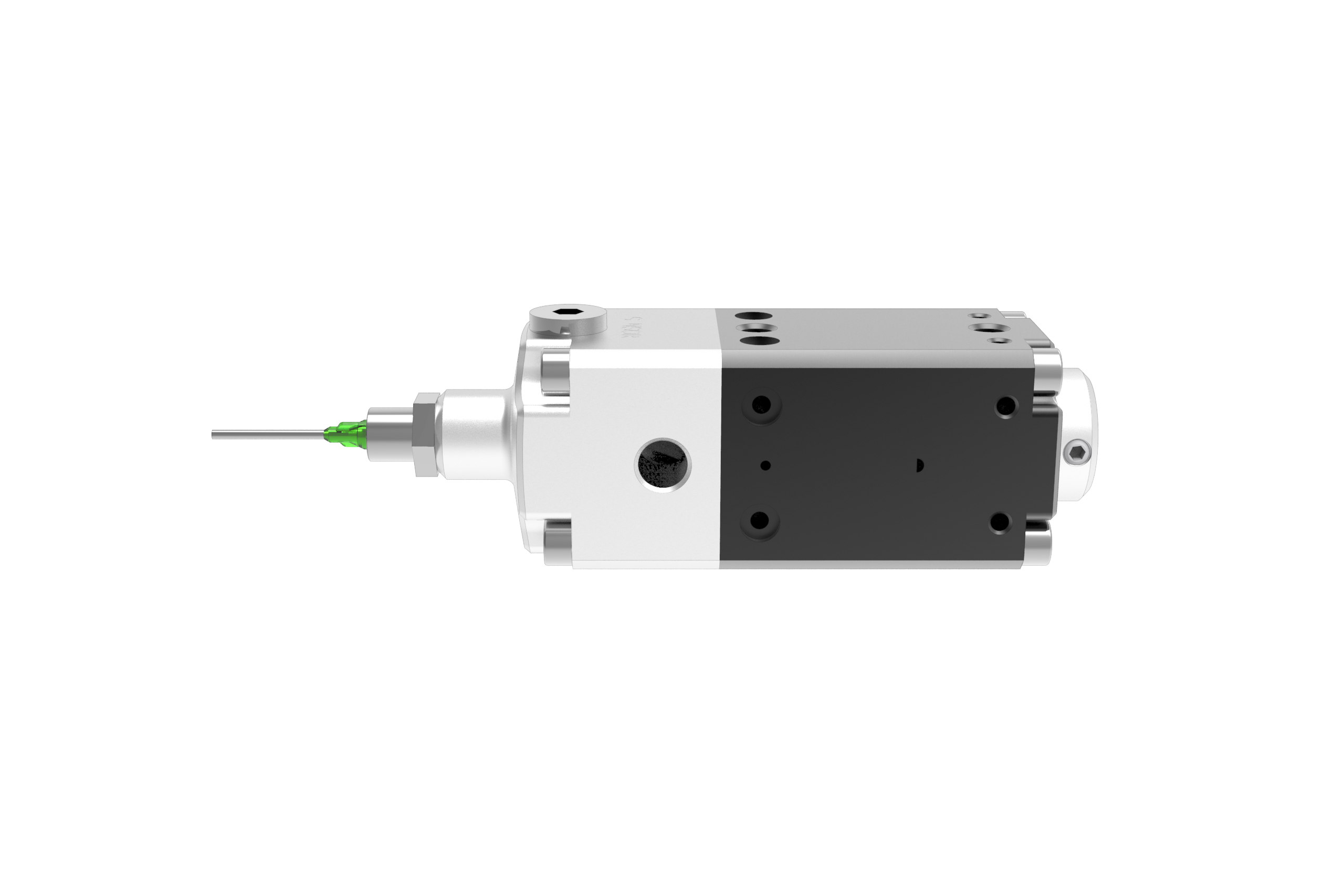

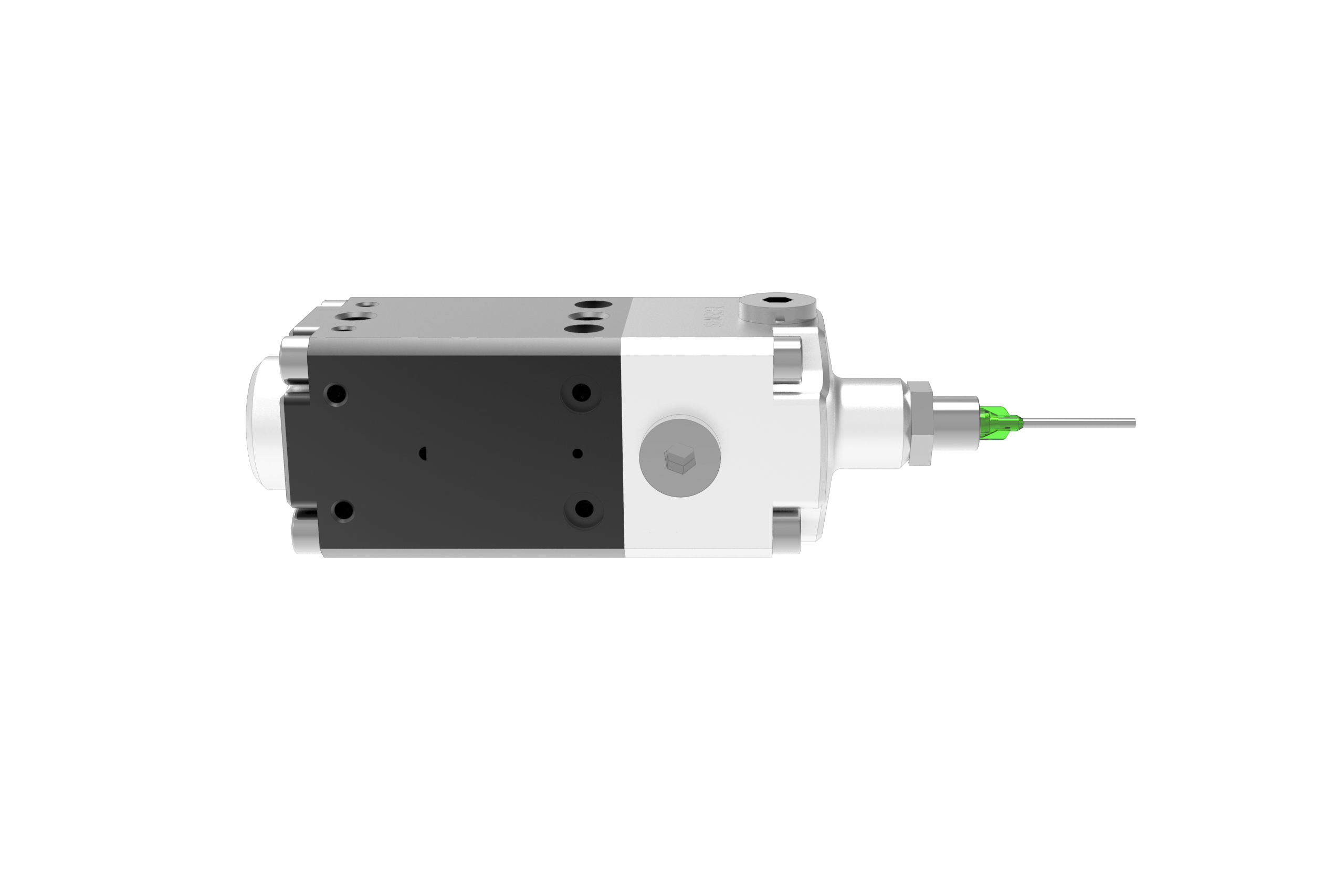

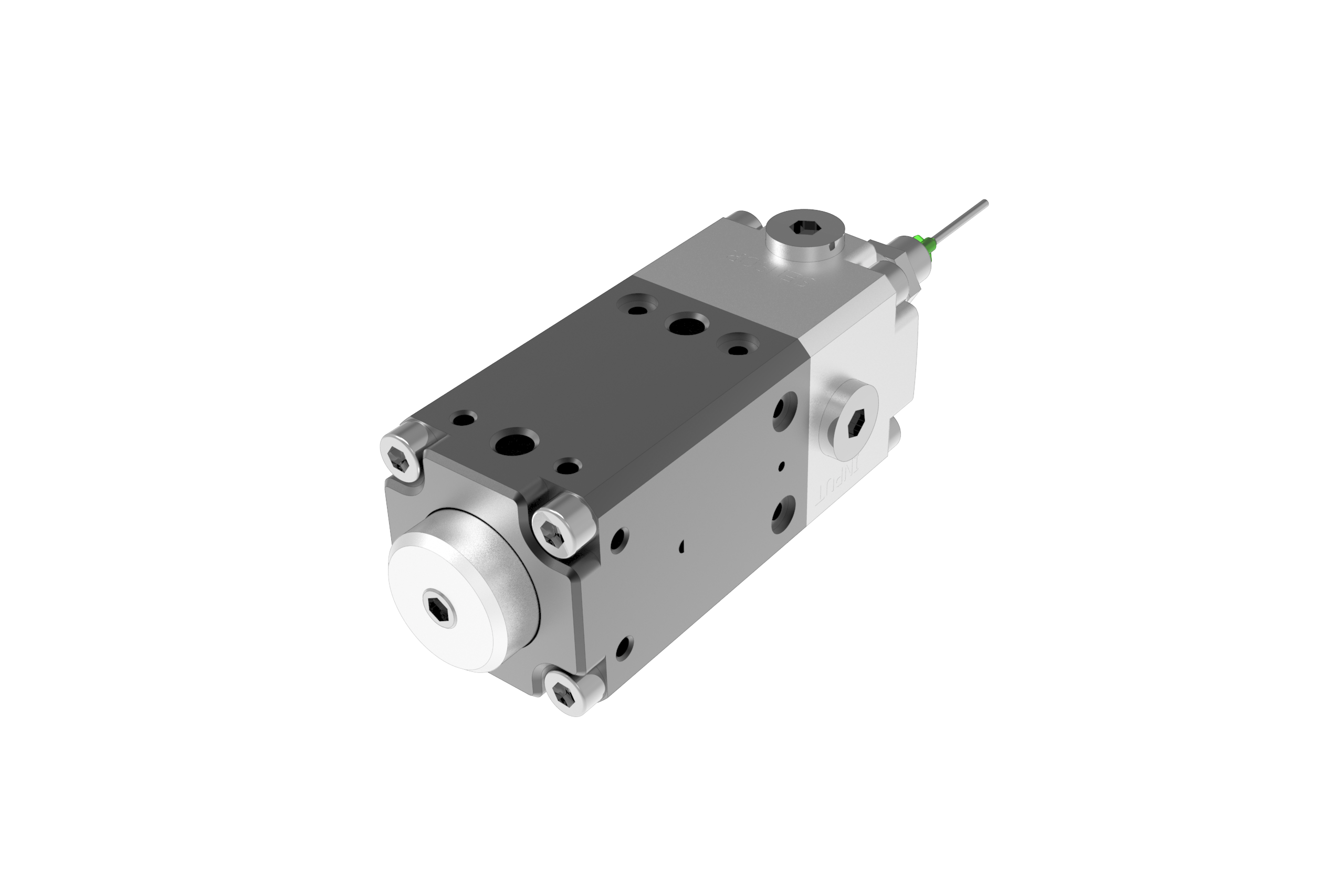

Diaphragm dispensing valve WMAV

The WMAV diaphragm dispensing valve is a robust and powerful dosing valve designed specifically for precise pressure-time dosing of reactive, highly viscous media such as polyurethanes, acrylates, epoxies, silicones, and gap fillers. With its innovative, low-wear design and the option to integrate additional sensors and heating elements, the WMAV provides a flexible solution for demanding dosing processes in modern production environments.

A key feature of the WMAV is its snuff-back effect, which ensures clean media cut-off at the dosing tip, preventing trailing threads and significantly enhancing application accuracy. As the outlet needle closes, it creates a slight vacuum that retracts the medium into the dosing tip, ensuring precise dosing without residue.

The specially designed diaphragm prevents ambient air from entering the valve, protecting moisture-sensitive media, such as certain adhesives, from premature curing. This feature ensures reliable operation, prevents clogging, and reduces the risk of valve damage. The complete sealing also helps avoid media carryover into the environment, supporting safe processing.

For all media-contacting components of the WMAV, only stainless steel (1.4301) combined with PTFE is used, making the valve highly resistant to abrasive and corrosive media, thereby significantly reducing wear. This choice of materials extends the valve’s lifespan and sustainably lowers maintenance costs. In the event of pneumatic failure, the valve’s automatic shut-off function prevents uncontrolled media release, protecting the production environment from contamination—a key contribution to process safety.

The WMAV operates reliably at working pressures up to 150 bar, delivering exceptional dosing accuracy through precise pressure and time control. Options for continuous process monitoring include needle stroke detection and pressure sensors. Additionally, integrated heating can be added to regulate valve temperature, adjusting the flow behavior of the medium to specific process requirements.

The valve is available in three sizes to meet various application needs:

- Size 1: Height 120.8 mm; Width x Depth 40 mm; Media inlet G 1/4"; Opening width 2 mm²

- Size 2: Height 120.8 mm; Width x Depth 40 mm; Media inlet G 1/4"; Opening width 4 mm²

- Size 3: Height 164 mm; Width x Depth 60 mm; Media inlet G 3/8"; Opening width 8 mm²

With a viscosity range of 50 to 1,000,000 mPas, the WMAV covers a wide range of applications and is suited for various media and material characteristics. The combination of precision, safety, and durability makes the Walther diaphragm dispensing valve an ideal choice for demanding production environments where reliable and efficient application of high-viscosity adhesives and sealants is essential.

- Innovative, low-wear design

- Suitable for adhesives and sealants

- Clean media cut-off thanks to snuff-back effect

- Continuous process monitoring possible through connection of additional sensors

- Option to integrate heating elements

- Working pressure: max. 150 [bar]

- Operating temperature: 0 to 80 [°C]

- Media-contacting materials: Stainless steel (1.4301), PTFE

- Viscosity range: 50 – 1,000,000 [mPas]

- Overall height:

- Size: 120.8 [mm]

- Size: 120.8 [mm]

- Size: 164 [mm]

- Width / Depth (square cross-section):

- Size: 40 [mm]

- Size: 40 [mm]

- Size: 60 [mm]

- Media inlet connection:

- Size: G 1/4"

- Size: G 1/4"

- Size: G 3/8"

- Opening width:

- Size: 2 [mm²]

- Size: 4 [mm²]

- Size: 8 [mm²]