Control and Diagnostic System WSDS

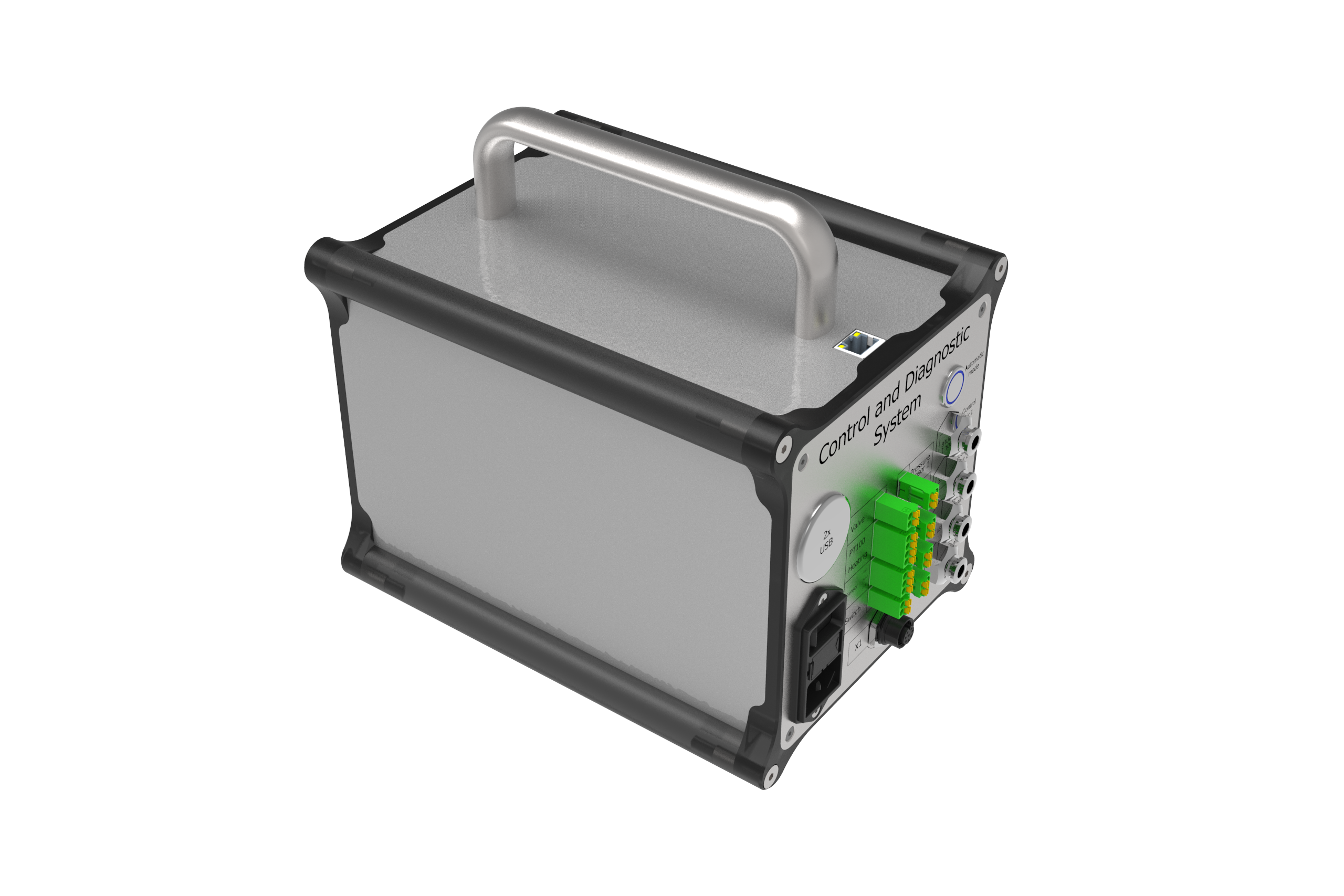

The WSDS Control and Diagnostic System combines important interfaces and helpful features for controlling individual components of your dosing system, and for checking, evaluating or optimizing the overall operation based upon recorded process data.

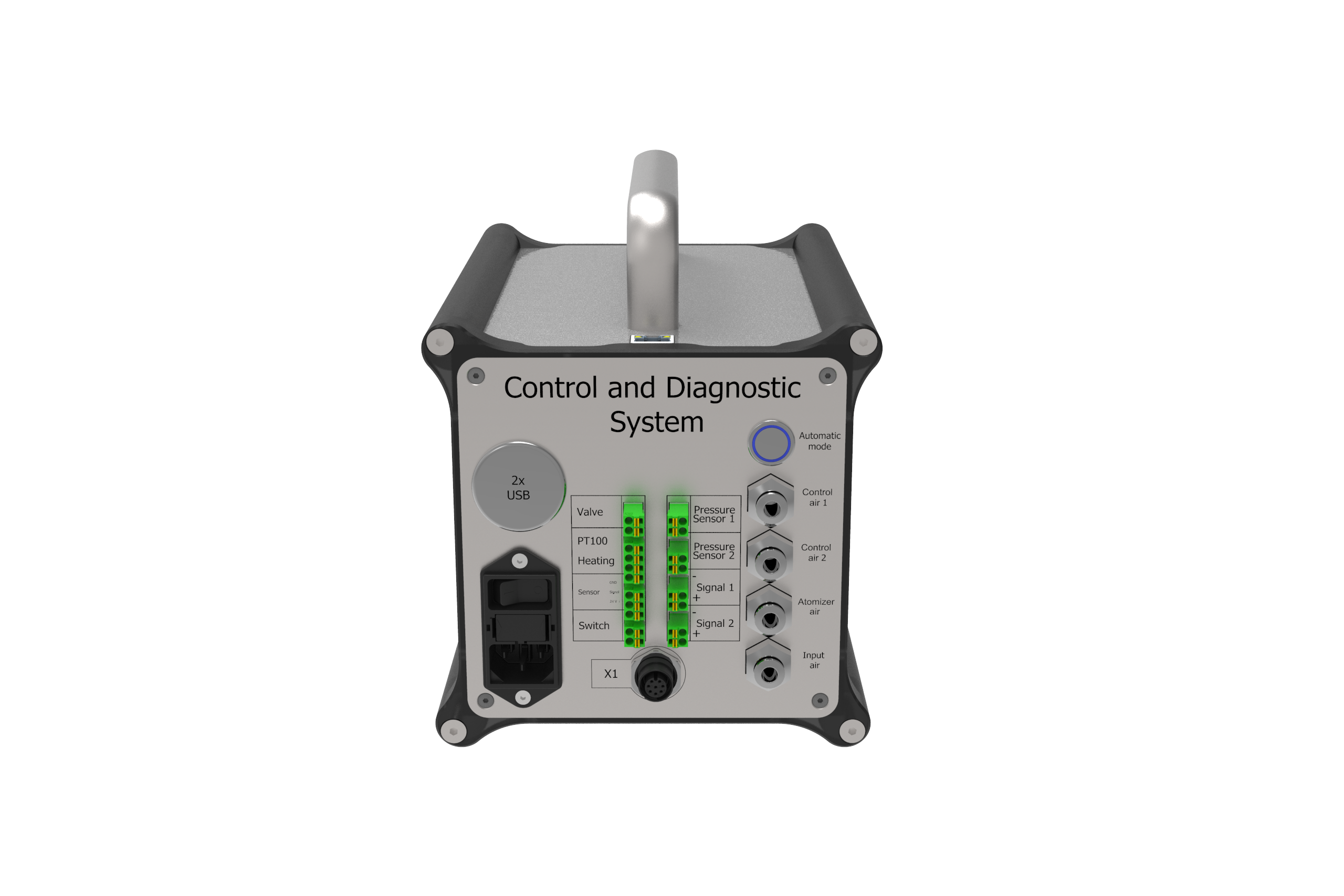

A web interface is used for parametering so that the system is independent from any platform and can be used and controlled with flexibility. Obtain reliable recordings of the values of spray, dosing and pulse valves, valve heatings, sensors such as the PT100 Temperature Sensor or the WLS Light Barrier, pressure sensors with analog outlet – or simply general digital control signals: The WSDS is a mobile combination of control and diagnostic unit and comes with electric, electro-pneumatic and pneumatic interfaces for a direct and system-independent control, for controlling and monitoring compressed air, control air, atomizer air, valves, sensors and heating plates.

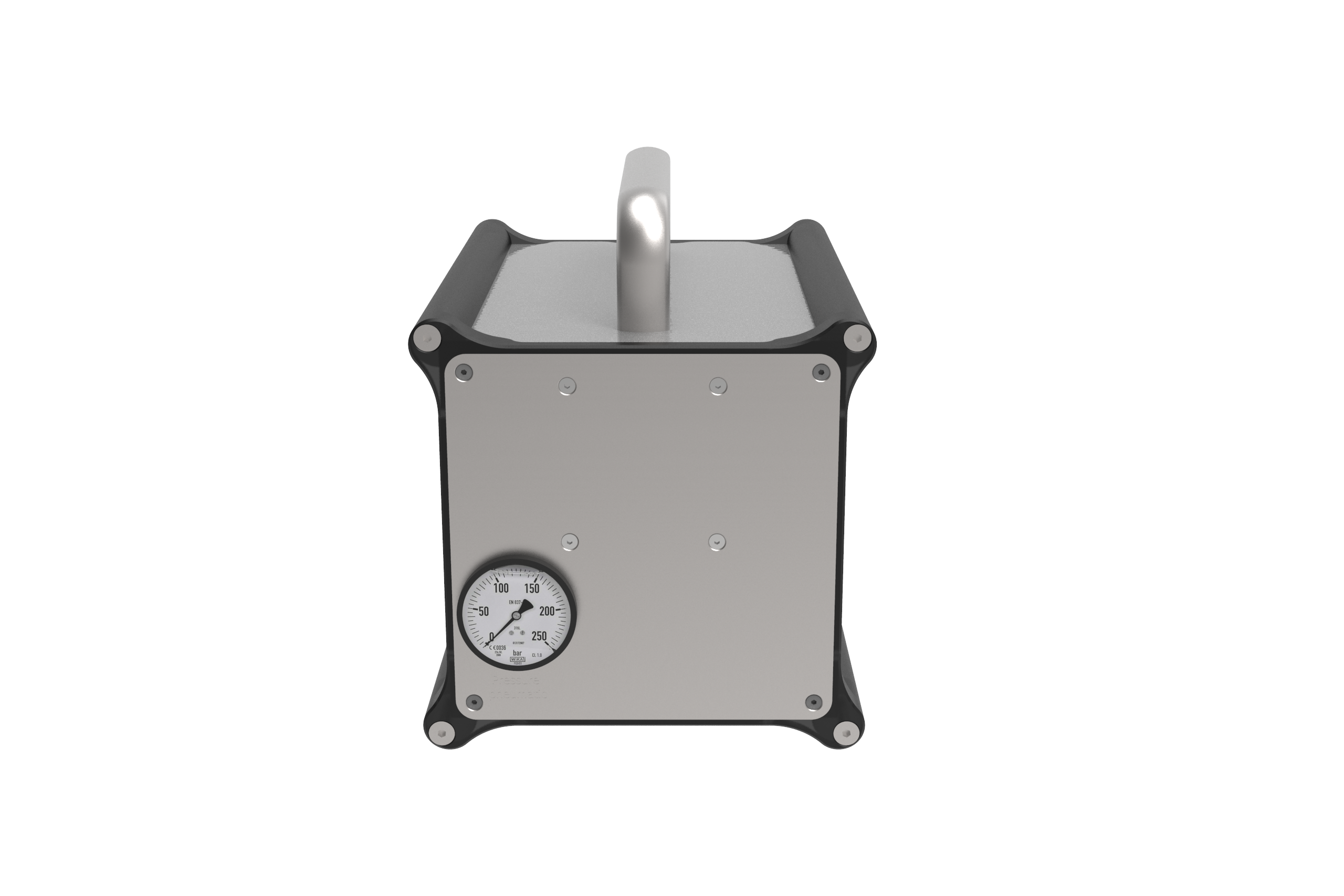

Visualization and parametering of the process parameters will be done with your PC or via the integrated network connection; or via tablet and Smartphone (W-LAN extension optional). All process data can be directly displayed, saved and retrieved at a later time. The WSDS has a compact design, is very flexible and needs only very little space. It comes with an additional, integrated pressure sensor, a temperature controller and a manometer.

- control, monitoring, and regulation of control, pressure, and atomizer air, valves, sensors, etc.

- capturing, visualizing, and storing individual parameters

- integrated pressure sensor, temperature controller, and manometer

- web-based Human-Machine Interface (HMI)

- inlet pressure (pneumatic): 4 to 10 [bar]

- supply voltage: 230 [VAC]

- control voltage: 24 [V]

- operating temperature: 10 to 50 [°C]

- weight: 5 [kg]

- dimensions (l x w x h): 245.9 x 170 x 211 [mm]

- software web interface