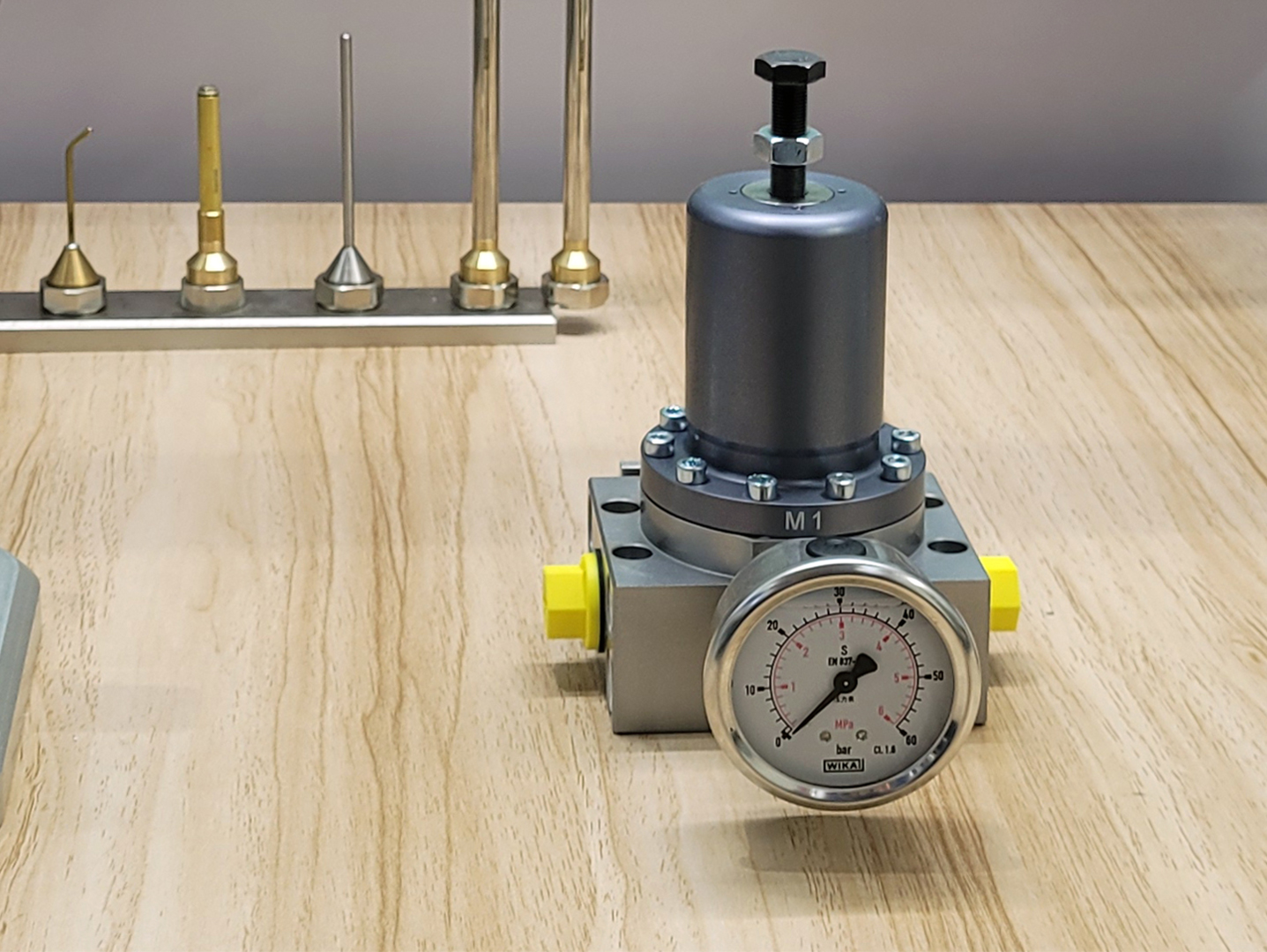

Automated dosing systems

8 Aug 2022, 09:15:00

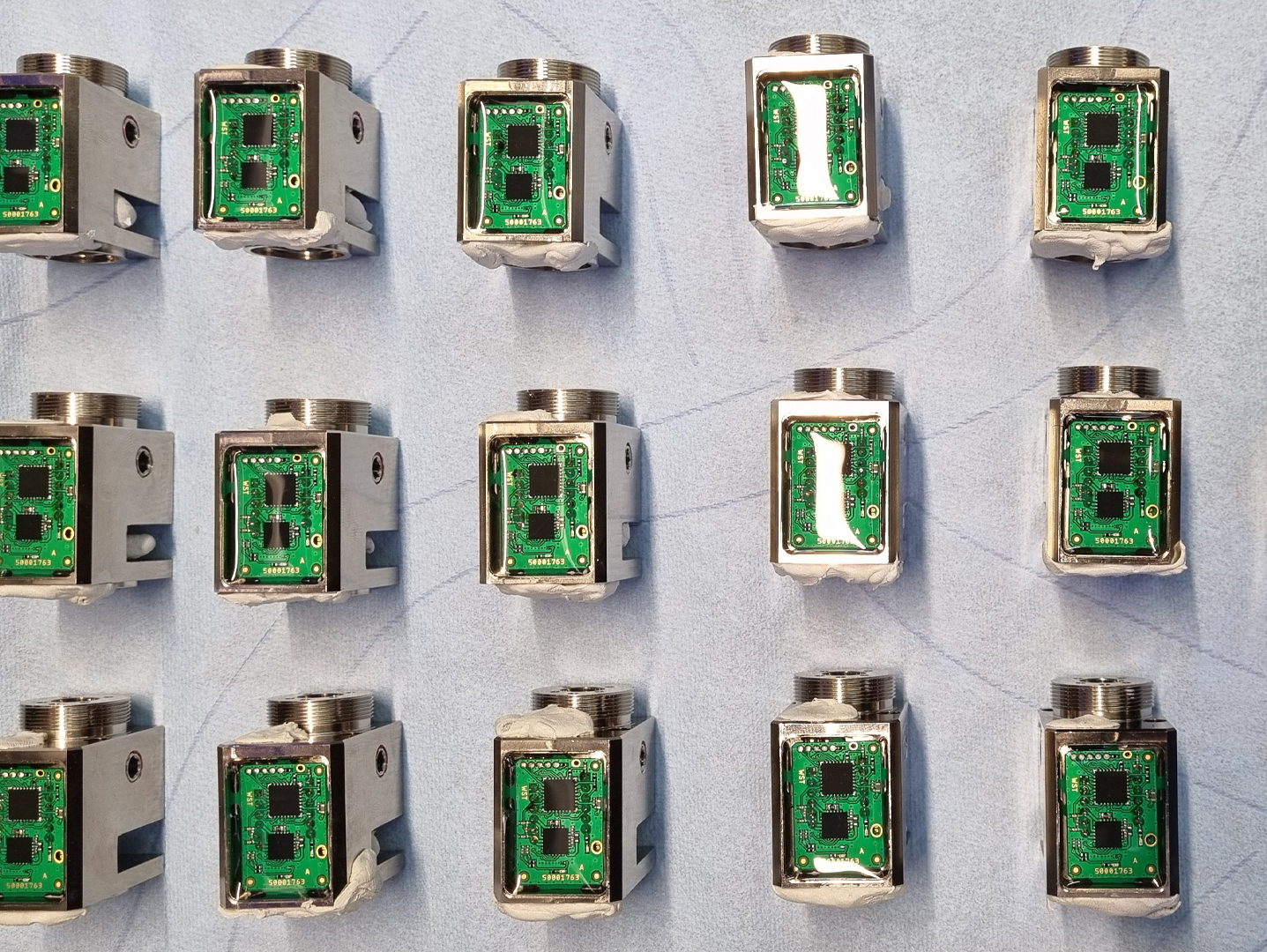

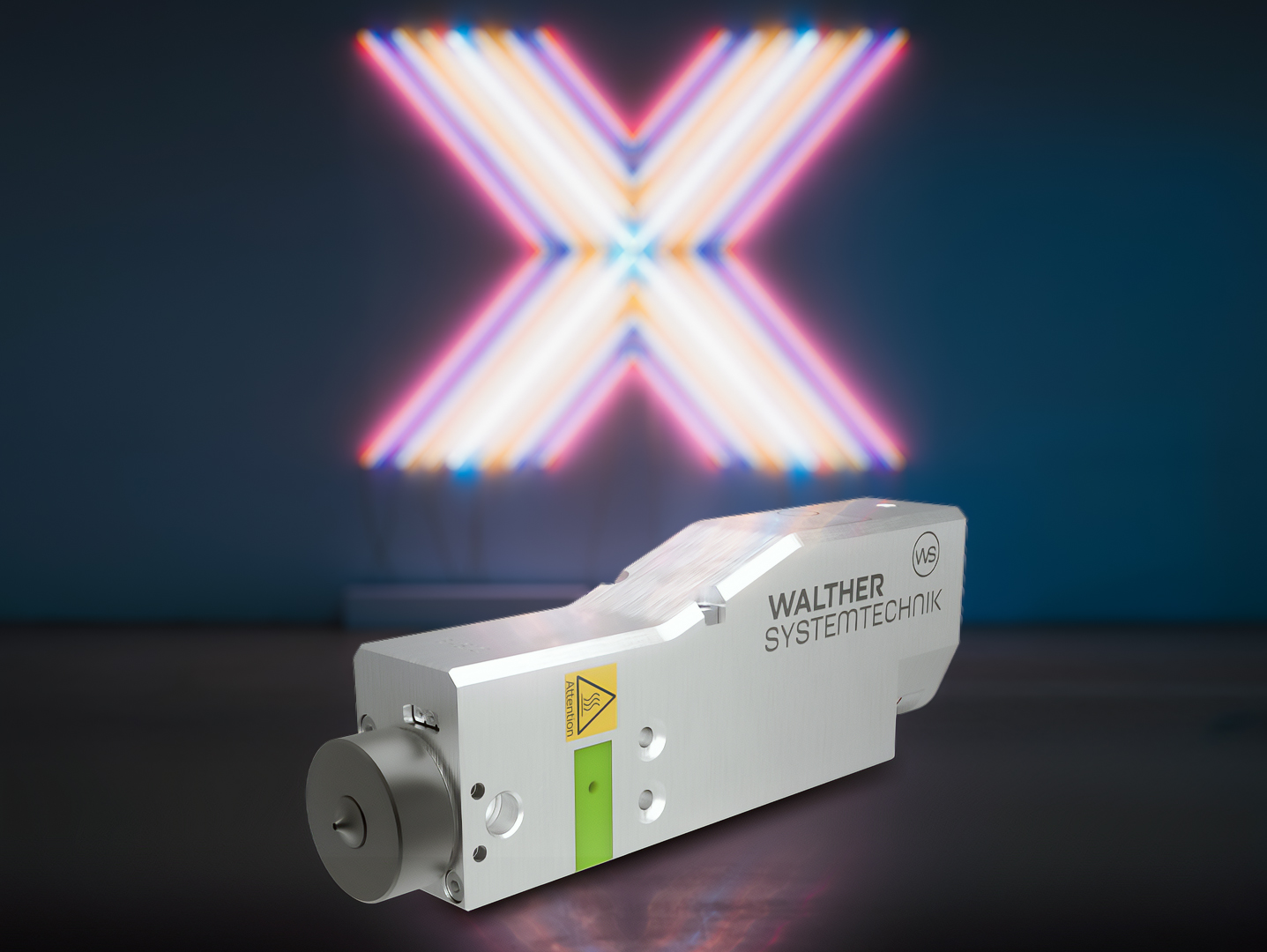

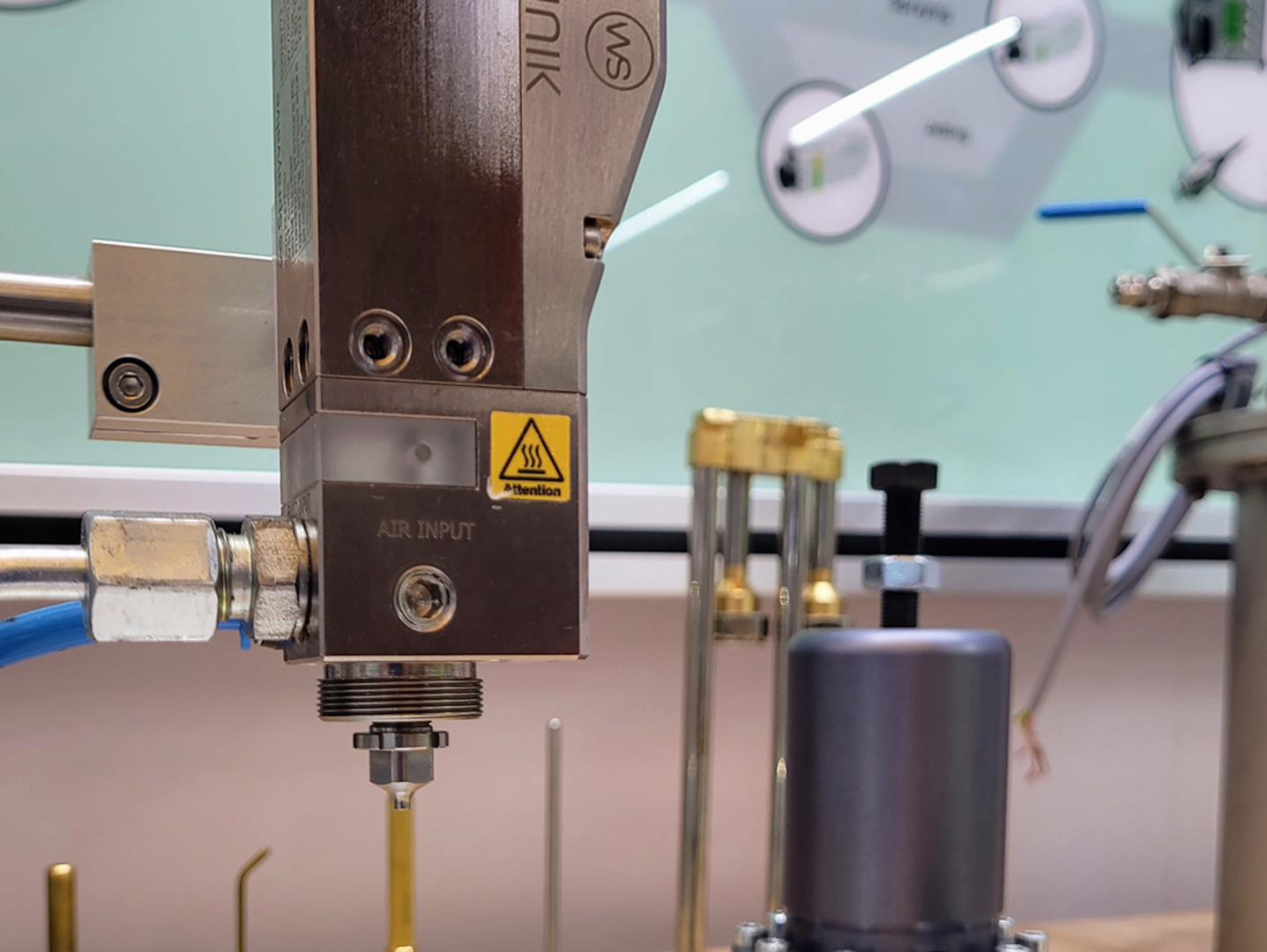

A dosing system provides several advantages over manual application of viscous fluids, improving the efficiency and quality of the production process.

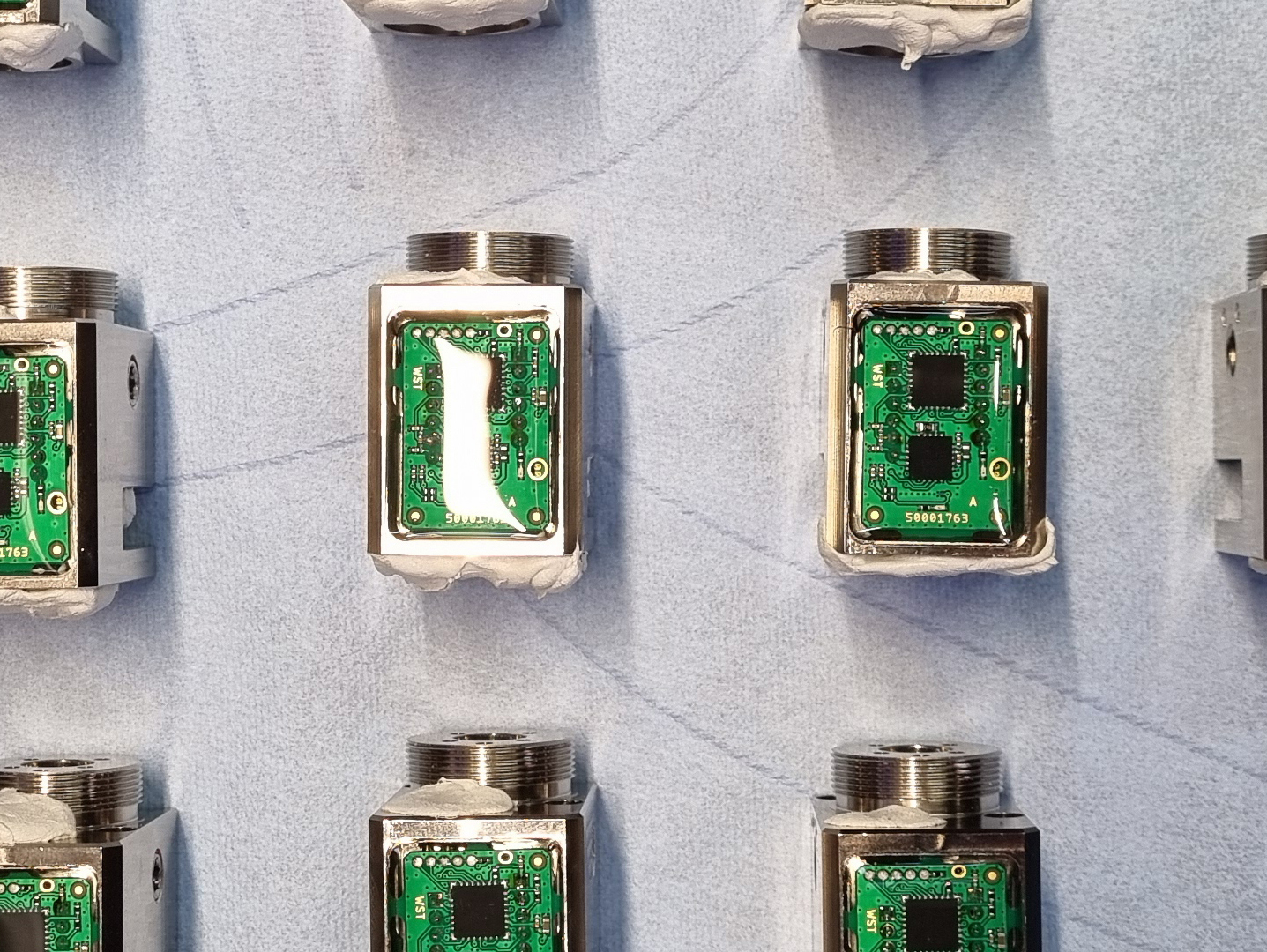

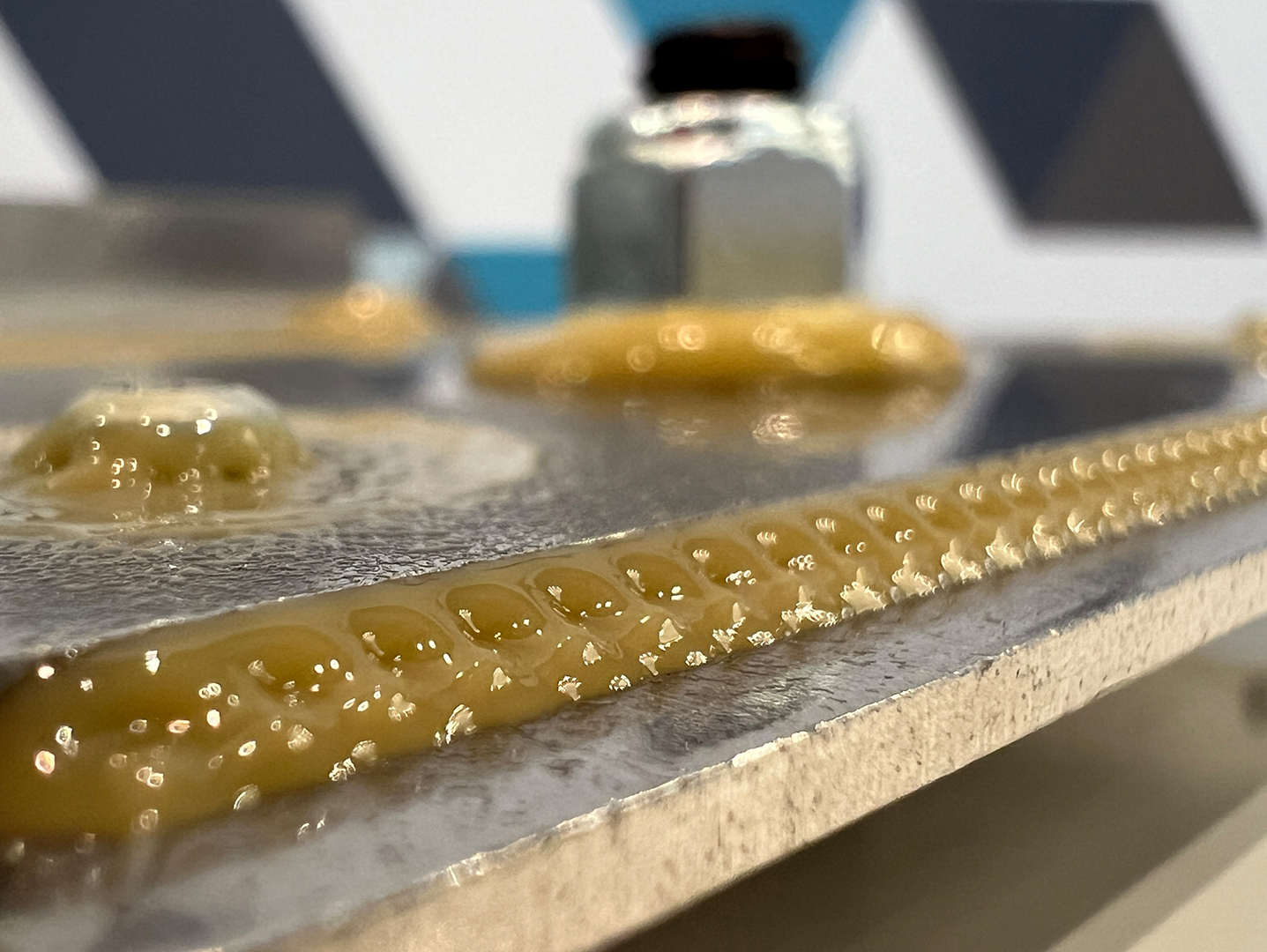

It enhances application quality and repeatability by achieving precise and consistent dosing, regardless of the operator's skills. The result? Consistent application quality and improved product quality.

The risk of over- or under-dosing is minimized thanks to accurate dosing, resulting in a reduced reject rate, less waste, increased productivity, and lower costs.

Additionally, a dosing system allows for precise control over fluid consumption. This approach saves materials, reduces costs, and promotes efficient utilization.

Additionally, dosing systems operate continuously and reliably, increasing availability for optimal production performance.

By quickly and accurately dosing the fluid, achievable cycle times are shortened. This results in increased production capacity and shorter lead times.

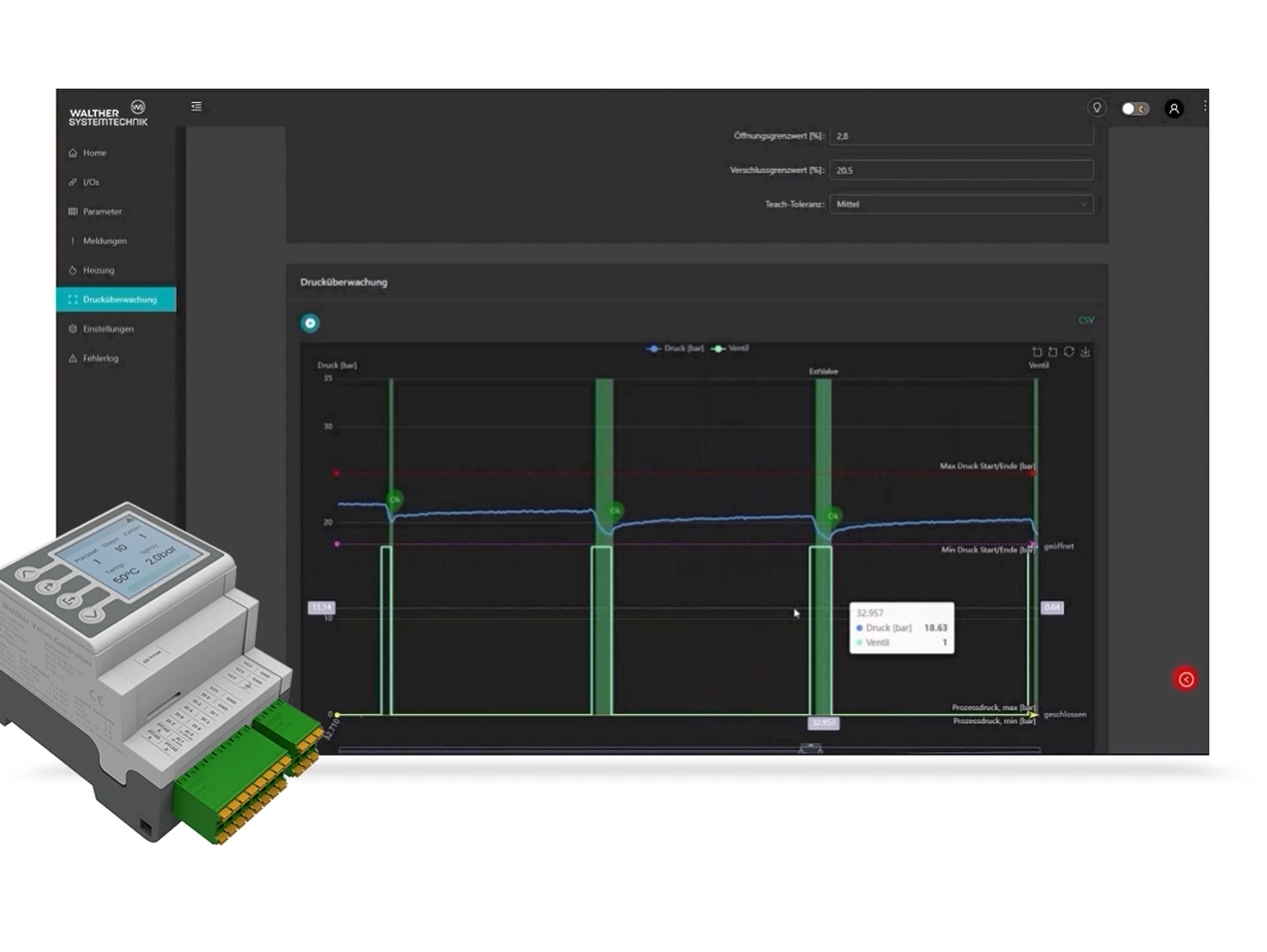

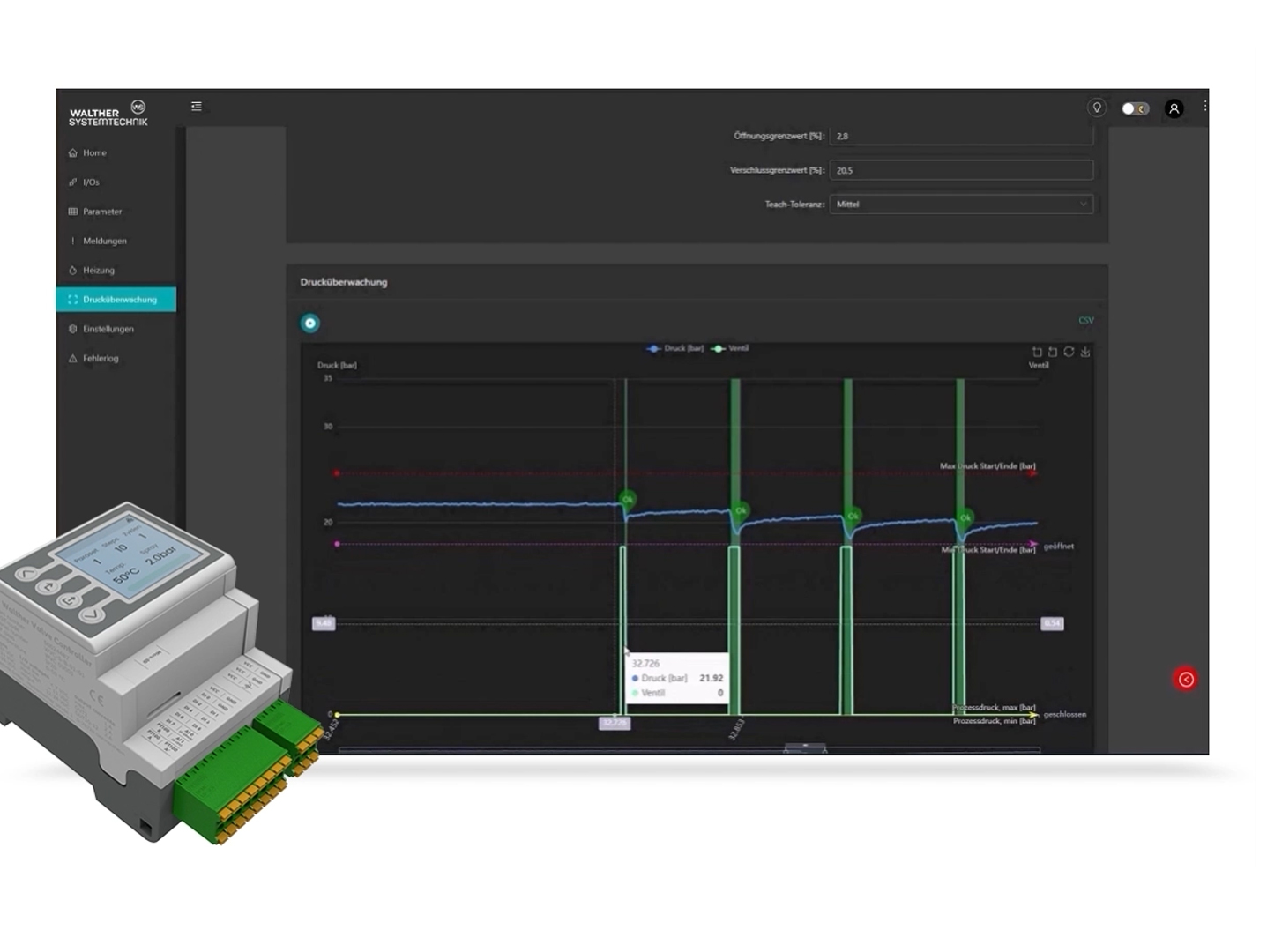

Dosing systems provide real-time monitoring and traceability of the dosing process, ensuring continuous quality control and early error detection.

Are you still applying for jobs manually or have you implemented dosing systems? Let's discuss how you can optimize your production process and benefit from increased quality, efficiency, and cost savings.

Automated dosing systems

A dosing system provides several advantages over manual application of viscous fluids, improving the efficiency and quality of the production process.

It enhances application quality and repeatability by achieving precise and consistent dosing, regardless of the operator's skills. The result? Consistent application quality and improved product quality.

The risk of over- or under-dosing is minimized thanks to accurate dosing, resulting in a reduced reject rate, less waste, increased productivity, and lower costs.

Additionally, a dosing system allows for precise control over fluid consumption. This approach saves materials, reduces costs, and promotes efficient utilization.

Additionally, dosing systems operate continuously and reliably, increasing availability for optimal production performance.

By quickly and accurately dosing the fluid, achievable cycle times are shortened. This results in increased production capacity and shorter lead times.

Dosing systems provide real-time monitoring and traceability of the dosing process, ensuring continuous quality control and early error detection.

Are you still applying for jobs manually or have you implemented dosing systems? Let's discuss how you can optimize your production process and benefit from increased quality, efficiency, and cost savings.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request